Combined exploitation gas mixed source proportion quantitative determination method of coal seam group

A technology for gas extraction and determination of methods, applied in gas discharge, mining equipment, measuring devices, etc., can solve problems such as potential safety hazards, failure to consider coal occurrence, gas parameter difference characteristics, standard evaluation, etc., to ensure production safety , to overcome the effects that cannot be quantitatively determined

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

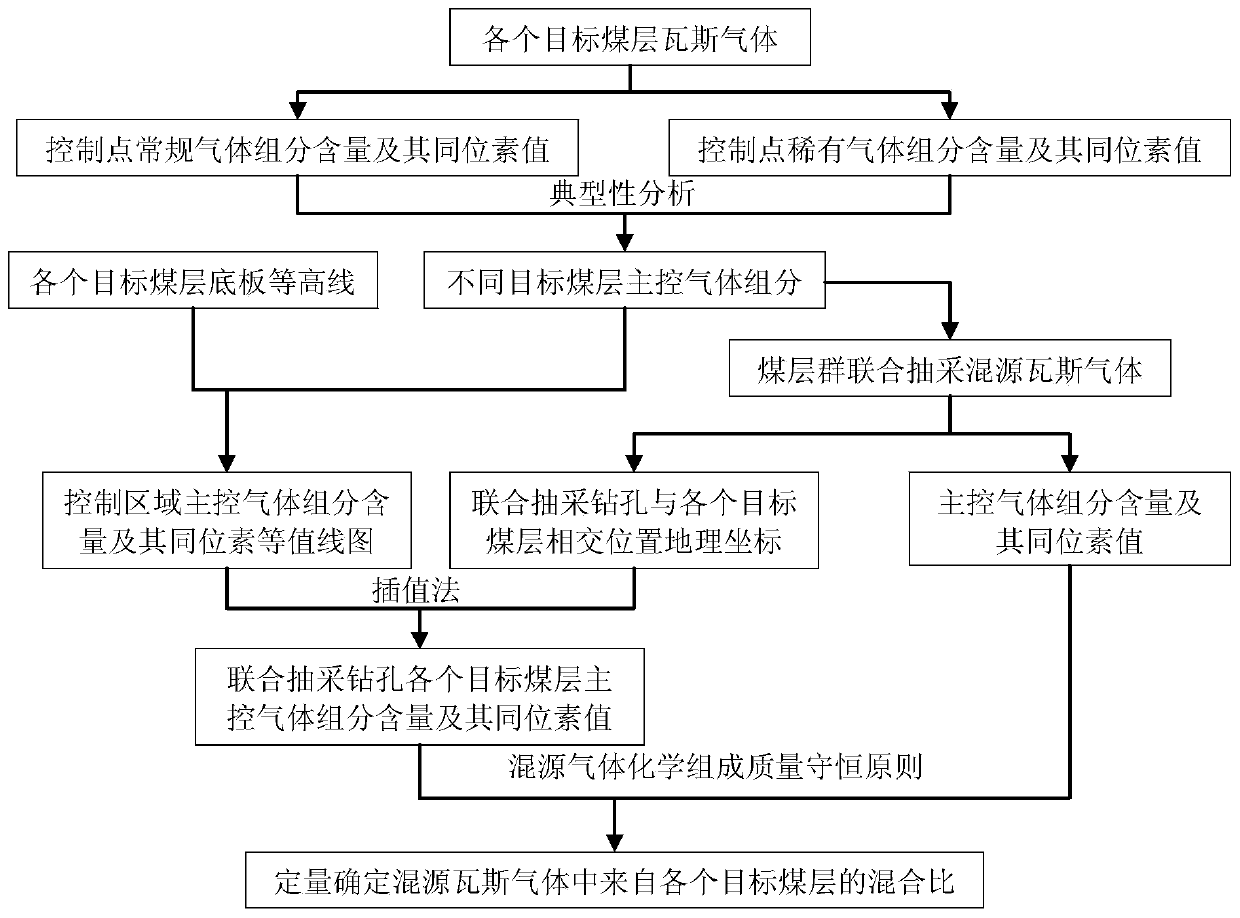

[0039] The implementation flow chart of a method for quantitatively determining the proportion of mixed sources of gas in coal seam group joint drainage is as follows figure 1 As shown, in conjunction with the determination method of the mixing ratio of mixed-source gas mixed in two coal seam groups composed of M6 coal seam 1 and M8 coal seam 2 in a coal mine in Southwest China as an example, the specific implementation process of the method of the present invention is described:

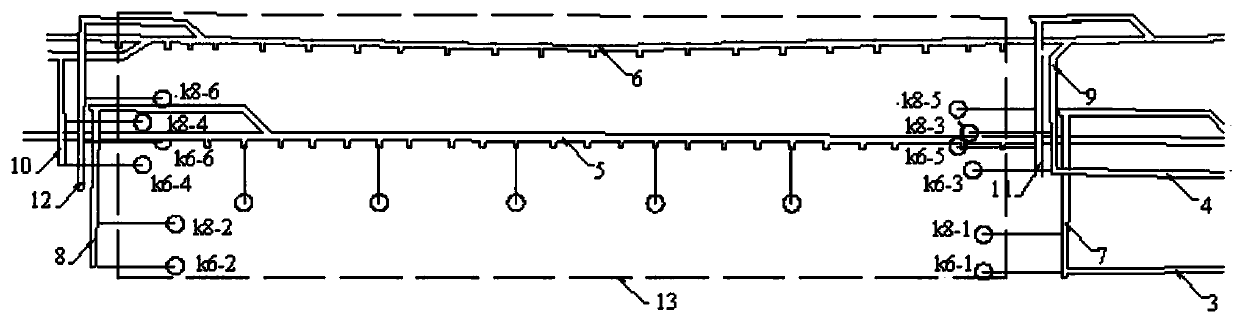

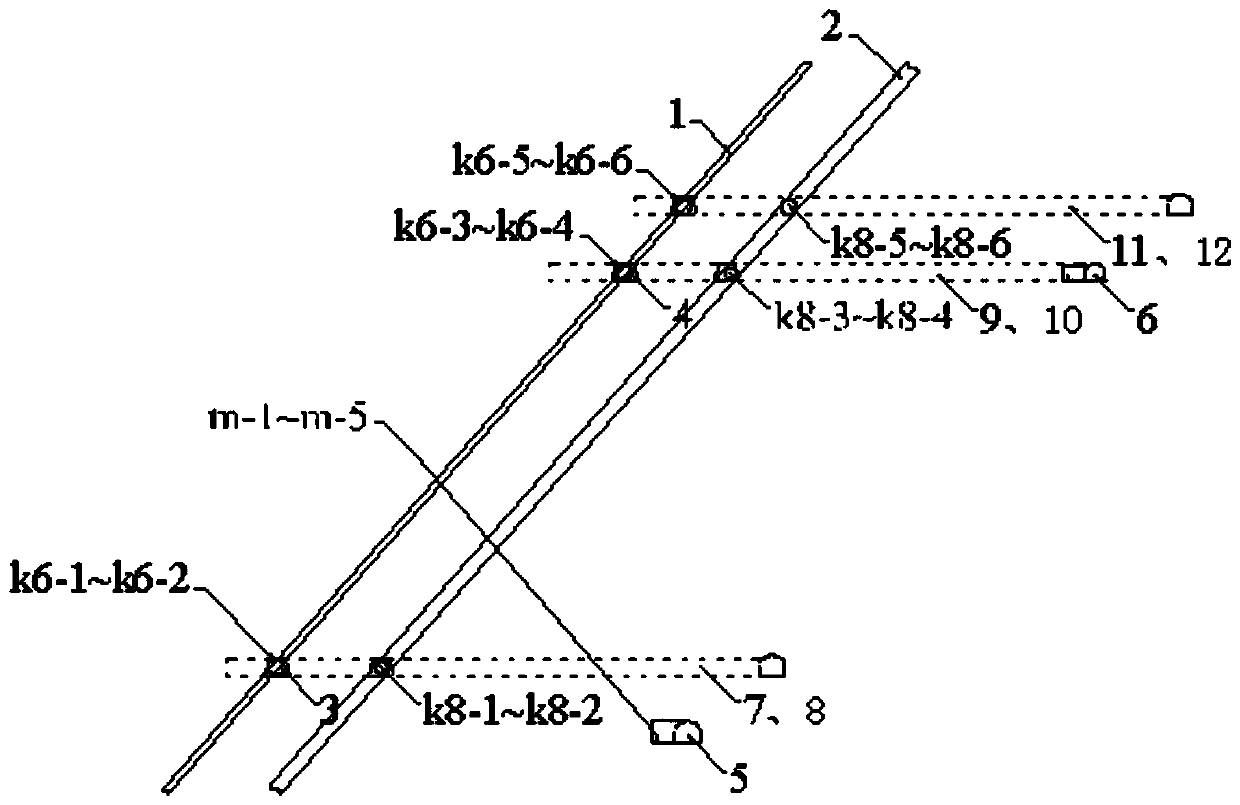

[0040] A coal mine test area in Southwest China such as figure 2 and image 3 As shown, the mine range includes M6 coal seam 1 and M8 coal seam 2. The mine has been arranged to complete the M6 coal seam return airway 3 and the M6 coal seam air inlet 4. The mine is designed in +300 main lane 5 and +380 main lane 6 Construction coal seam group joint drainage drilling, coal seam group joint drainage drilling end point coordinate coverage range is the control area 13.

[0041] M6 coal seam contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com