Qualitative and quantitative analysis method for high-pressure liquid material

A technology for high-pressure liquid and liquid components, which is applied in the field of quantitative analysis and qualitative analysis of high-pressure liquid materials, can solve the problems of long residence time, difficult detection of liquid materials, low detection efficiency, etc. The effect of high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0176] The preparation method of the present invention will be further described in detail below in conjunction with specific examples. It should be understood that the following embodiments are only illustrative and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies implemented based on the foregoing contents of the present invention are covered by the scope of the present invention.

[0177] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples, unless otherwise specified, can be obtained from commercial sources.

Embodiment 1

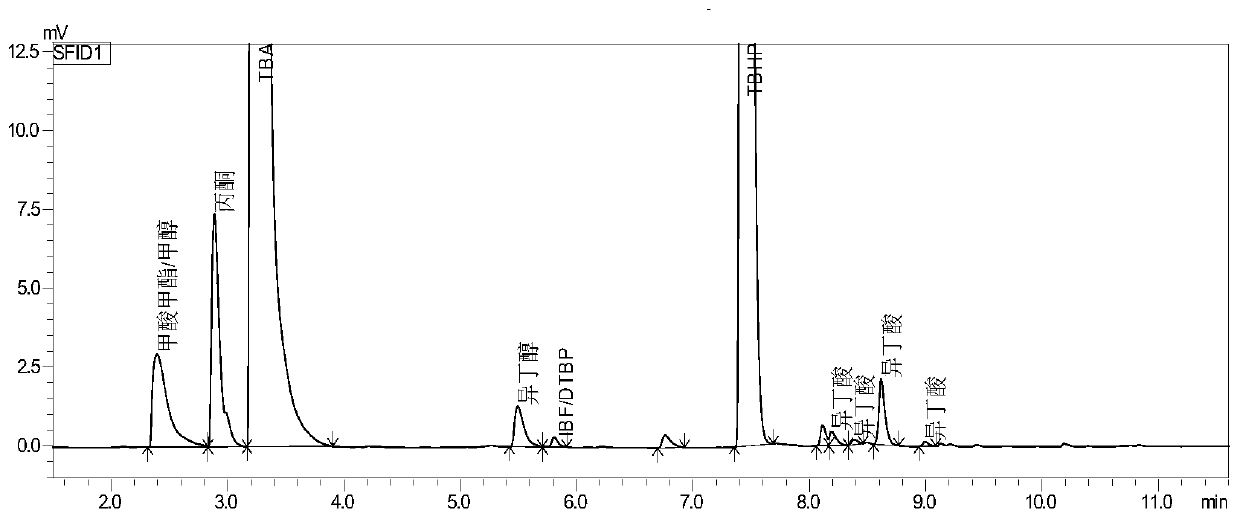

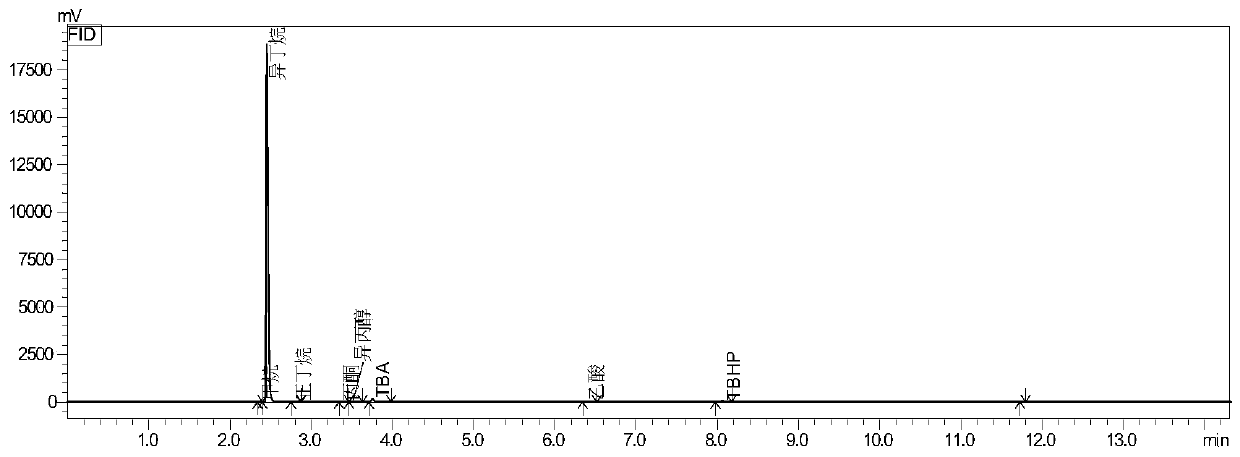

[0179] 1 The sample is the high-pressure liquid material obtained after the pilot test of isobutane oxidation

[0180] 2 sample pretreatment

[0181] Weigh and sample the cylinder to the nearest 0.01g and record it as m 0 . Add about 150g of water to a three-necked flask with a shut-off valve, accurate to 0.01g, and record the weight as M 1 ; Weigh the total mass of the sampled cylinder m 1 , Accurate to 0.01g. Connect the three-necked flask with the sampling small steel bottle, and connect the sampling bag with the other interface of the three-necked flask. After connection, the entire system is evacuated. Then fill the entire system with high-purity nitrogen to replace the air in the system. After the replacement is completed, close the nitrogen filling valve. Slowly open the cylinder outlet valve to avoid splashing of bubbles emerging from the liquid surface, and release the liquid within 8-10 minutes. Replace the nitrogen in the gas bag with the overflowing gas. After the sa...

Embodiment 2

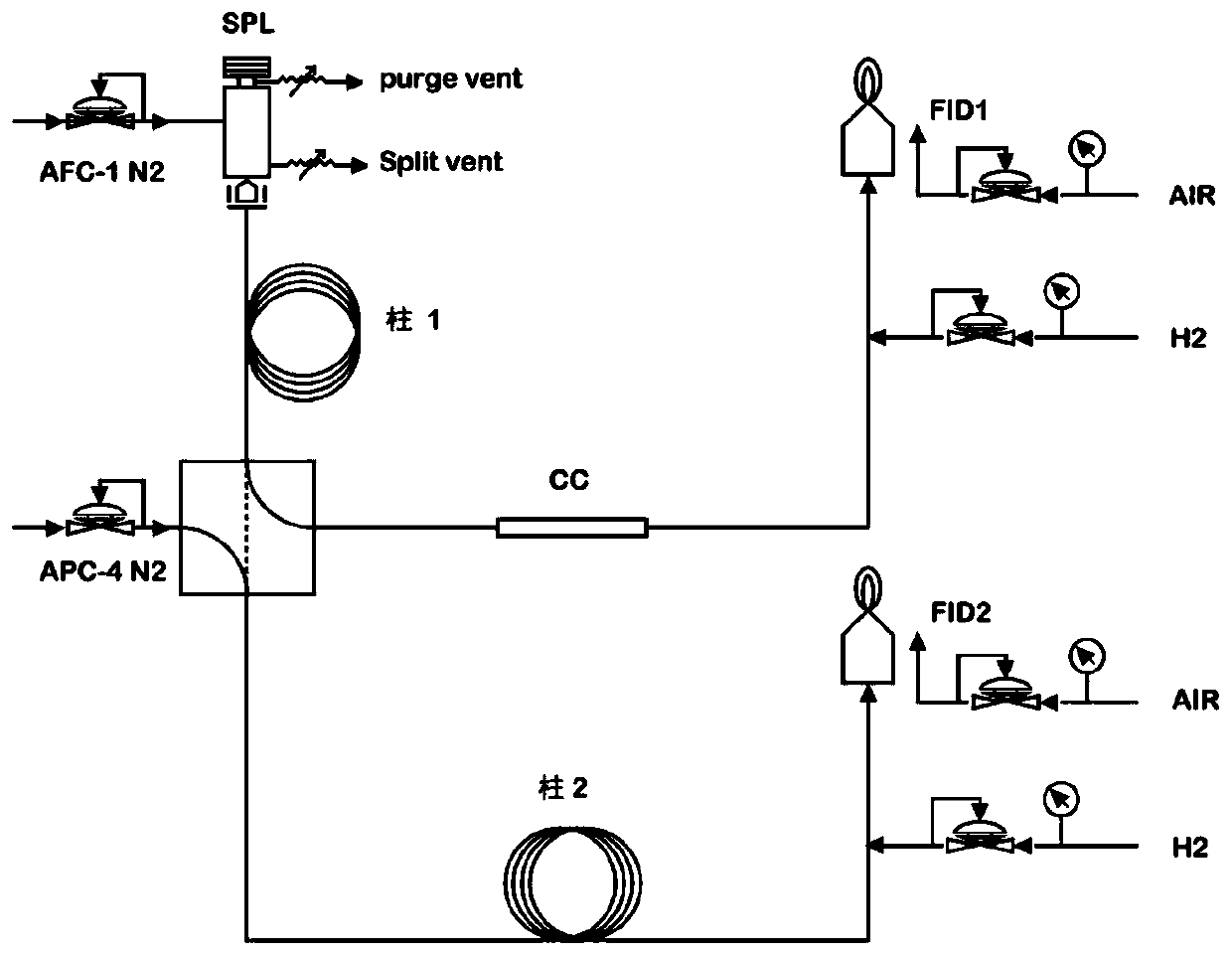

[0225] This embodiment provides a detection unit for liquid components. The detection unit includes a gas chromatograph, a sixth chromatographic column, a first detector, a second detector, an automatic flow controller, and an automatic pressure controller; the gas phase The chromatograph includes an injection port, a fourth chromatographic column, a fifth chromatographic column, and a heart-cutting part; one end of the fourth chromatographic column is connected to the injection port of the gas chromatograph, and the other end is connected to the inlet of the heart-cutting part, The first outlet end of the heart-cutting component is connected to the first detector through the sixth chromatographic column; the second outlet end is connected to the fifth chromatographic column, and the outlet end of the fifth chromatographic column is connected to the second detector;

[0226] The first detector and the second detector are thermal conductivity cell detectors or hydrogen flame ioniza...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com