Optical fiber automatic plate arranging equipment

An automatic optical fiber arrangement technology, applied in the direction of bundled optical fibers, fiber mechanical structures, etc., can solve the problems affecting the internal image transmission quality of optical fiber image transmission components, affecting the performance of optical fiber light transmission and image transmission, thin cortex thickness, etc., to achieve Fast visualization, monitorable production process, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

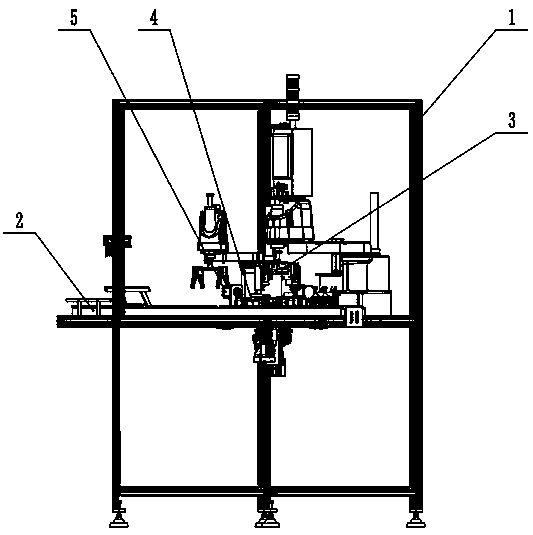

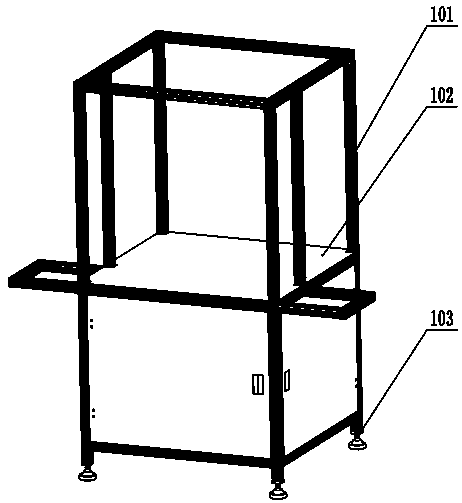

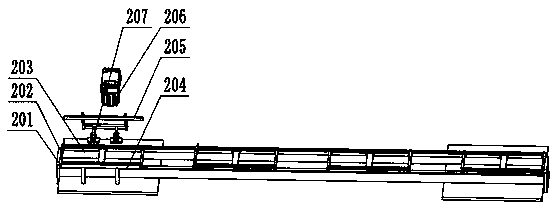

[0021] see Figure 1 to Figure 6As shown, the optical fiber automatic board arrangement device of the present invention has novel structure, rich functions, high degree of automation, improved work efficiency, avoids human participation, saves production costs, and ensures processing quality; it adopts PLC and human-computer interaction interface , improve the degree of equipment automation and visualization, making the operation more convenient and fast; the whole machine fully considers the reliability design, and carries out modular design to facilitate future maintenance and management. The structure includes a body frame 1, a cleaning and surface quality inspection mechanism 2, a material clamping mechanism 3, a panel assembly mechanism 4, and a binding mechanism 5. The cleaning and surface quality inspection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com