Femtosecond laser direct writing and DMD maskless photoetching integrated printing equipment

A maskless lithography and femtosecond laser technology, which is applied in the field of integrated equipment for large-area processing of micro-nano structures, can solve the problems of processing failure, high cost of femtosecond lasers, and shell collapse, and save processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

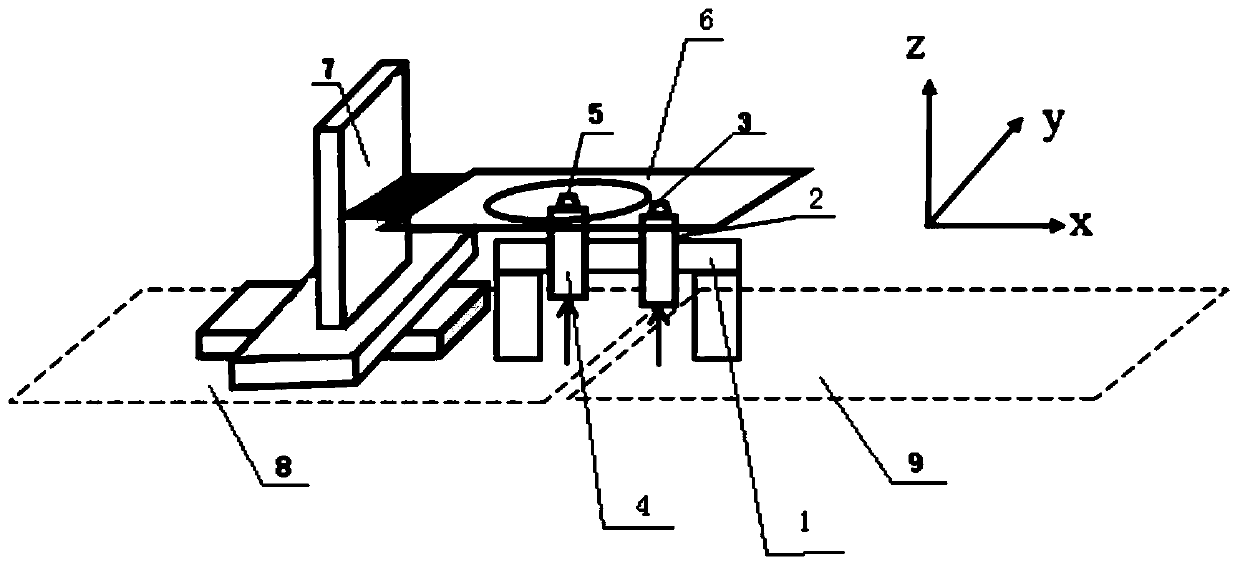

[0019] Femtosecond laser direct writing and DMD maskless photolithography integrated printing equipment, such as figure 1 Shown: including motion platform 1, DMD maskless lithography system projection objective adjustment sleeve 2, DMD maskless lithography system projection objective lens 3, femtosecond laser direct writing system microscopic objective adjustment sleeve 4, femtosecond laser Direct writing system microscope objective lens 5, sample holder 6, three-dimensional precision controllable displacement platform 7, femtosecond laser direct writing system 8 and DMD maskless photolithography system 9, the distance between the moving platform 1 and the optical platform is 35 cm, and the The DMD maskless lithography system projection objective lens adjustment sleeve 2 and the femtosecond laser direct writing system microscopic objective lens adjustment sleeve 4 are both arranged on the motion platform 1, and the DMD maskless lithography system projection objective lens 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com