Layered MXene loaded cobalt ferrite composite wave-absorbing material and preparation method thereof

A composite wave-absorbing material, cobalt ferrite technology, applied in the direction of electrical components, magnetic field/electric field shielding, etc., can solve the problem of low wave-absorbing performance, achieve low production cost, broadband strong electromagnetic wave absorption characteristics, and facilitate impedance matching Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment includes the following steps:

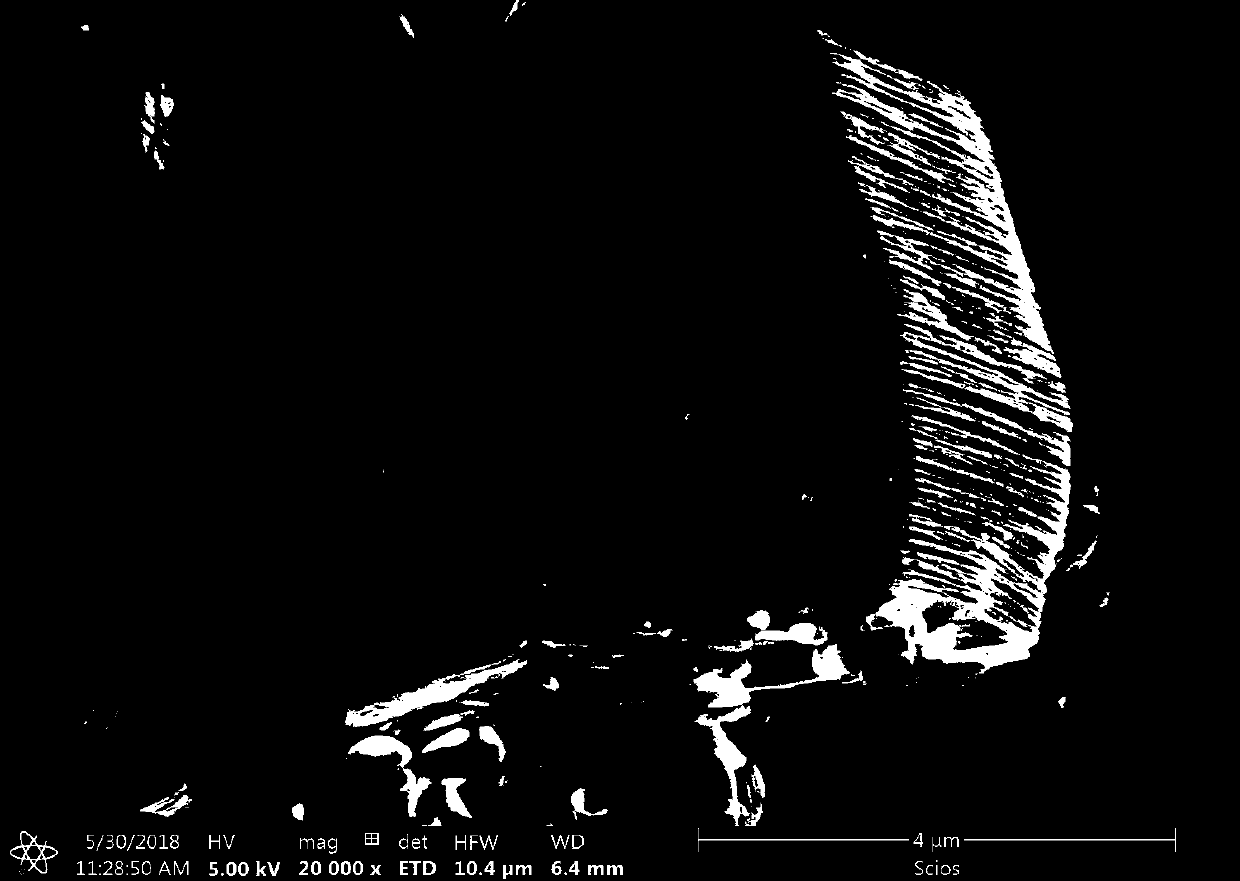

[0026] (1) Preparation of lamellar MXene; weigh 5gTi 3 SiC 2 The MAX phase powder was poured into a 500 ml polytetrafluoroethylene beaker filled with a hydrofluoric acid solution with a mass concentration of 40%, and magnetically stirred at a speed of 300 r / min for 24 h under the ultrasonic assistance of a power of 40 W; After the reaction was completed, the above mixed solution was allowed to stand for 2 h and then the supernatant was removed, then the black precipitate was washed 3 times with deionized water, then filtered and dried at 80° C. for 2 h to obtain MXene powder; The microscopic morphology of the test powder is as follows: figure 1 As shown, it can be seen that the MXene prepared by the present invention presents a lamellar microstructure with uniform morphology;

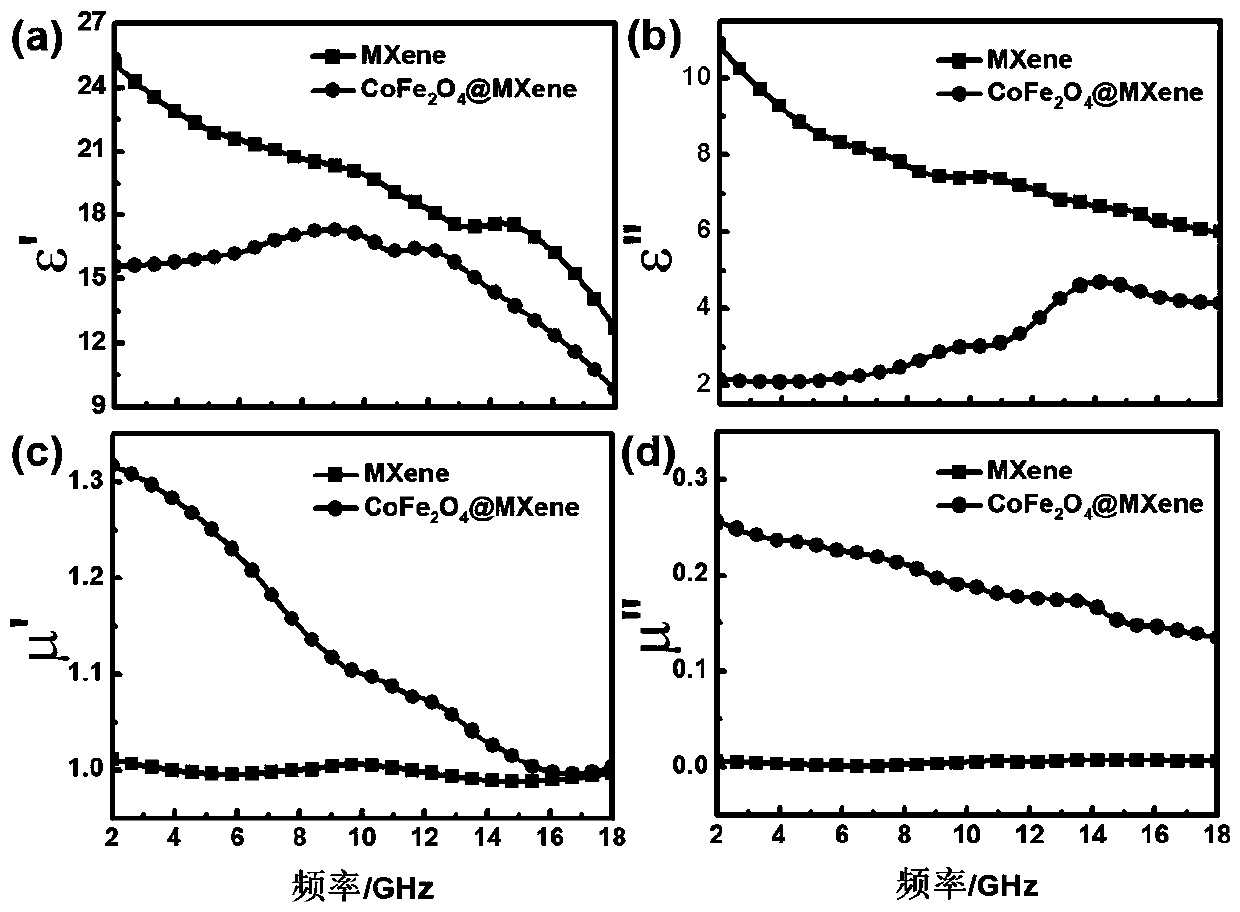

[0027] (2) Preparation of lamellar MXene-loaded cobalt ferrite composite absorbing material; weigh 1.2g CoCl 2 •6H 2 O and 4.1g Fe(NO 3 ) 2...

Embodiment 2

[0031] This embodiment includes the following steps:

[0032] (1) Preparation of lamellar MXene: Weigh 6gTi 3 AlC 2 The MAX phase powder was poured into a 500 mL polytetrafluoroethylene beaker filled with a 40% hydrofluoric acid solution, and stirred magnetically at a speed of 300 r / min for 12 h under the assisted action of ultrasound with a power of 60 W; After the reaction, the above mixture was left to stand for 2 hours and the supernatant was removed, then the black precipitate was washed 4 times with deionized water, then filtered and dried at 60°C for 2 hours to obtain a lamellar MXene powder;

[0033](2) Preparation of lamellar MXene-loaded cobalt ferrite composite absorbing material: weigh 2.4g CoCl 2 •6H 2 O and 5.4g Fe(Cl) 2 •6H 2 O, and dissolved in a glass flask filled with 500 mL of deionized water; pour the lamellar MXene powder obtained above into the mixed aqueous solution, and disperse evenly with magnetic stirring at 250 r / min for 5 h; Slowly add ammoni...

Embodiment 3

[0035] This embodiment includes the following steps:

[0036] (1) Preparation of lamellar MXene: Weigh 8gTi 3 SiC 2 The MAX phase powder was poured into a 500 mL polytetrafluoroethylene beaker filled with a 40% hydrofluoric acid solution, and stirred magnetically at a speed of 400 r / min for 18 h under the assistance of an ultrasonic power of 80 W; After the reaction was over, the above mixture was left to stand for 3 hours and then the supernatant was removed, then the black precipitate was washed 5 times with deionized water, then filtered and dried at 60°C for 3 hours to obtain MXene powder;

[0037] (2) Preparation of lamellar MXene-loaded cobalt ferrite composite absorbing material: Weigh 8.7g Co(NO 3 ) 2 •6H 2 O and 24.2g Fe(NO 3 ) 2 •9H 2 O, and dissolved in a glass flask filled with 500 mL of deionized water. Pour the lamellar MXene powder obtained above into the mixed aqueous solution, and disperse uniformly with magnetic stirring at 500 r / min for 3 h; slowly a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com