Formula and method for preparing freeze-dried powder containing oligopeptide-1

A technology of freeze-dried powder and oligopeptide, which is applied in pharmaceutical formulations, preparations for skin care, and medical preparations containing active ingredients, etc. It can improve skin elasticity, strengthen skin barrier, and promote cell regeneration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

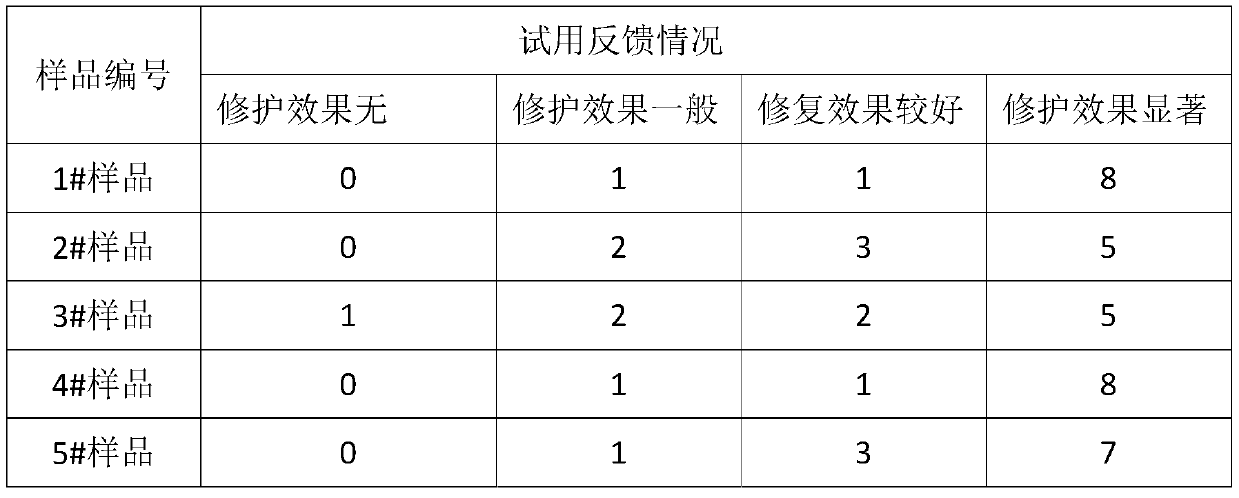

Examples

Embodiment 1

[0029] The lyophilized powder preparation method of the present embodiment is as follows:

[0030] (1) Weigh the material according to the following formula for preparing the lyophilized powder containing oligopeptide-1:

[0031] Water: 83%; Oligopeptide-1: 10%; Mannitol: 7%;

[0032] (2) Mix water and mannitol, raise the temperature to 75° C., stir and mix evenly, and cool down to obtain a mixed material body;

[0033] (3) Cool down the mixed material body to 40°C, add oligopeptide-1, stir and mix evenly, and continue to cool down;

[0034] (4) After the material cools down to 30°C, pour the material body into a glass bottle, and take it out of the pot after being frozen and sublimated.

[0035] The freeze-dried powder prepared in this example has better shaping effect.

Embodiment 2

[0037] The lyophilized powder preparation method of the present embodiment is as follows:

[0038] (1) Weigh the material according to the following formula for preparing the lyophilized powder containing oligopeptide-1:

[0039] Water: 89%; Oligopeptide-1: 5%; Mannitol: 6%;

[0040] (2) Mix water and mannitol, raise the temperature to 80° C., stir and mix evenly, and cool down to obtain a mixed material body;

[0041] (3) Cool down the mixed material body to 45°C, add oligopeptide-1, stir and mix evenly, and continue to cool down;

[0042] (4) After the material cools down to 35°C, pour the material body into a glass bottle, and take it out of the pot after freezing and sublimating.

[0043] The freeze-dried powder prepared in this example has better shaping effect.

Embodiment 3

[0045] The lyophilized powder preparation method of the present embodiment is as follows:

[0046] (1) Weigh the material according to the following formula for preparing the lyophilized powder containing oligopeptide-1:

[0047] Water: 87%; Oligopeptide-1: 5%; Mannitol: 8%;

[0048] (2) Mix water and mannitol, raise the temperature to 78°C, stir and mix evenly, and cool down to obtain a mixed material body;

[0049] (3) Cool down the mixed material body to 43°C, add oligopeptide-1, stir and mix evenly, and continue to cool down;

[0050] (4) After the material cools down to 32°C, pour the material body into a glass bottle, and take it out of the pot after freezing and sublimating.

[0051] The freeze-dried powder prepared in this example has better shaping effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com