Environment-friendly anti-freezing corrosion-resistant fire-fighting fluid and preparation method thereof

A kind of fire-fighting liquid and environmental protection technology, which can be applied to fire-fighting equipment and other directions, can solve the problem of easy freezing of fire-fighting water, and achieve the effect of ensuring fire-fighting safety and stable behavior.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] In order to solve the problem that fire-fighting water is easy to freeze when the temperature is low, the invention provides an environmentally friendly antifreeze and anti-corrosion fire-fighting liquid and a preparation method thereof, which is used for fire-fighting and can replace fire-fighting water below zero in winter.

[0028] The degree of polymerization of the fatty alcohol polyvinyl ether in the present invention is 10-15; the degree of polymerization of the sodium polyacrylate is 1000. The fatty alcohol polyvinyl ether is also called fatty alcohol polyoxyethylene ether. All raw materials used are chemically pure.

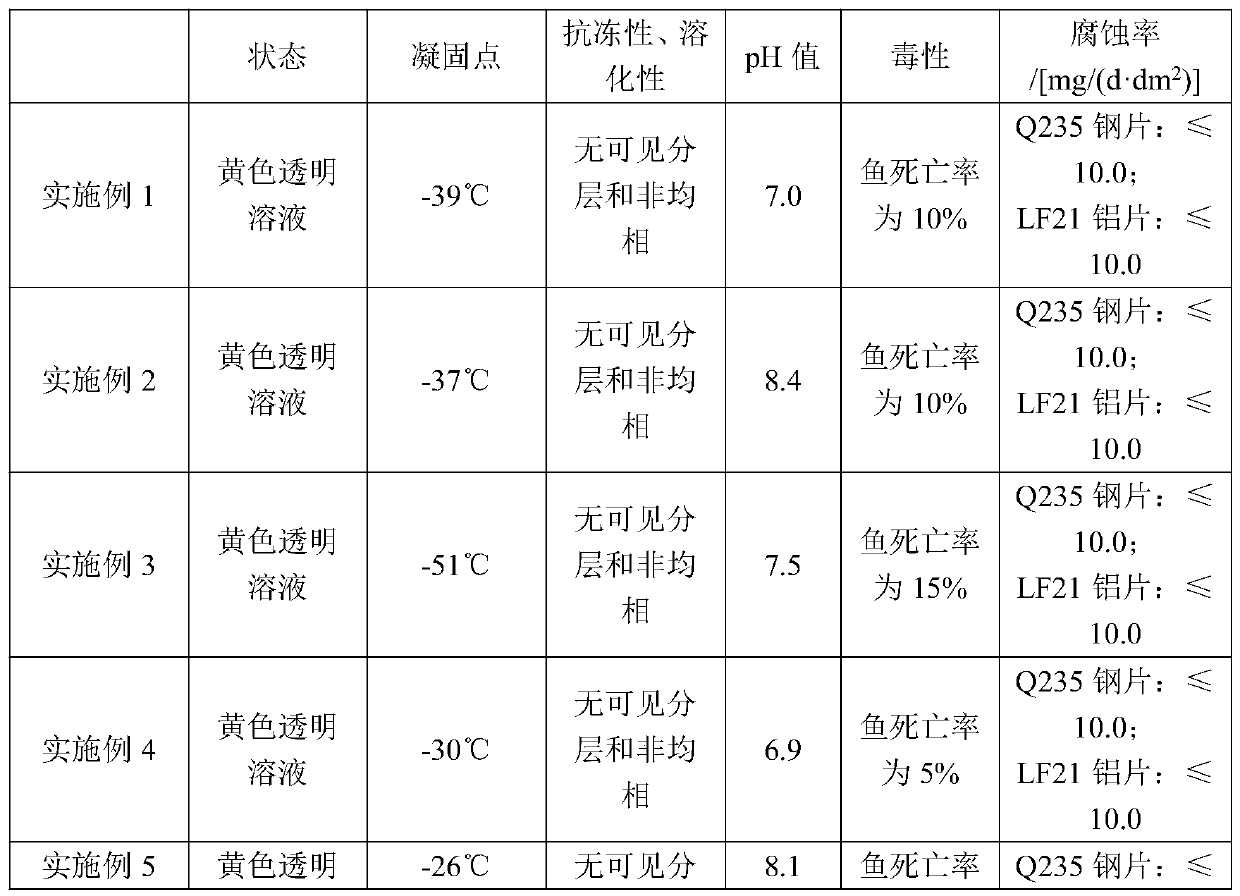

Embodiment 1

[0030] The environment-friendly antifreeze and anti-corrosion fire-fighting liquid described in this embodiment is composed of the following components by mass percentage: 14.25% of magnesium chloride, 20% of magnesium acetate, 10% of calcium chloride, 5% of potassium bicarbonate, 10% of carbonamide, and 0.4% of phytic acid. %, 0.15% of fatty alcohol polyvinyl ether, 0.15% of hexadecylamine, 0.05% of sodium polyacrylate (PAAS for short), 40% of water, and the sum of the mass percentages of the above components is 100%.

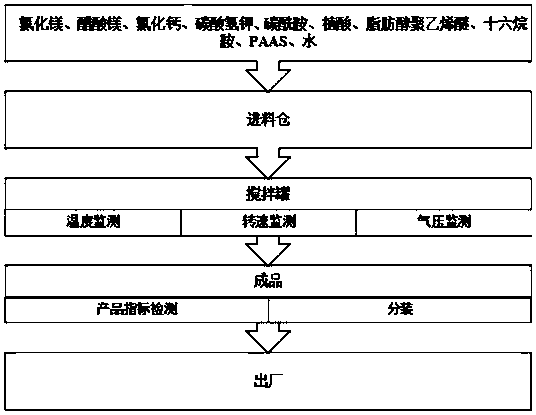

[0031] The preparation method of environmental protection antifreeze anti-corrosion fire fighting liquid described in the present embodiment comprises the following steps (see figure 1 ):

[0032] (1) Weigh 14.25kg of magnesium chloride, 20kg of magnesium acetate, 10kg of calcium chloride, 5kg of potassium bicarbonate, 10kg of carbonamide, 0.4kg of phytic acid, 0.15kg of fatty alcohol polyvinyl ether, and 0.15kg of cetylamine according to mass percentage , so...

Embodiment 2

[0036] The environment-friendly antifreeze and anti-corrosion fire-fighting fluid described in this embodiment is composed of the following components by mass percentage: 8% magnesium chloride, 25% magnesium acetate, 15% calcium chloride, 5% potassium bicarbonate, 6% carbonamide, and 0.55% phytic acid. %, fatty alcohol polyvinyl ether 0.05%, hexadecylamine 0.05%, sodium polyacrylate 0.005%, water 40.345%, the sum of the mass percentages of the above components is 100%.

[0037] The preparation method of the environment-friendly antifreeze and anti-corrosion fire-fighting liquid described in the present embodiment comprises the following steps:

[0038] (1) Take by weight percentage 8kg of magnesium chloride, magnesium acetate 25kg, calcium chloride 15kg, potassium bicarbonate 5kg, carbonamide 6kg, phytic acid 0.55kg, fatty alcohol polyvinyl ether 0.05kg, cetylamine 0.05kg, Sodium polyacrylate 0.005kg, water 40.345kg, spare;

[0039] (2) add each raw material that step (1) tak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com