Laser CMT composite welding system, welding method and aluminum alloy vehicle body welding component

A hybrid welding and welding method technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problem of molten pool gas not escaping pores in time, reducing and other problems, and achieves low cost, good process stability, and low welding The effect of heat input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

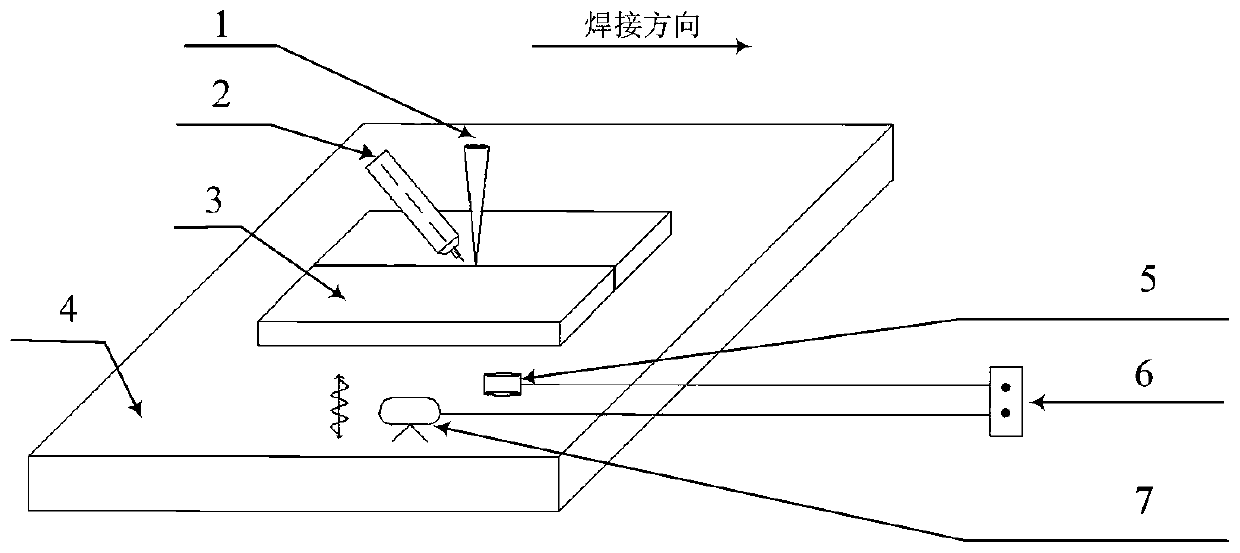

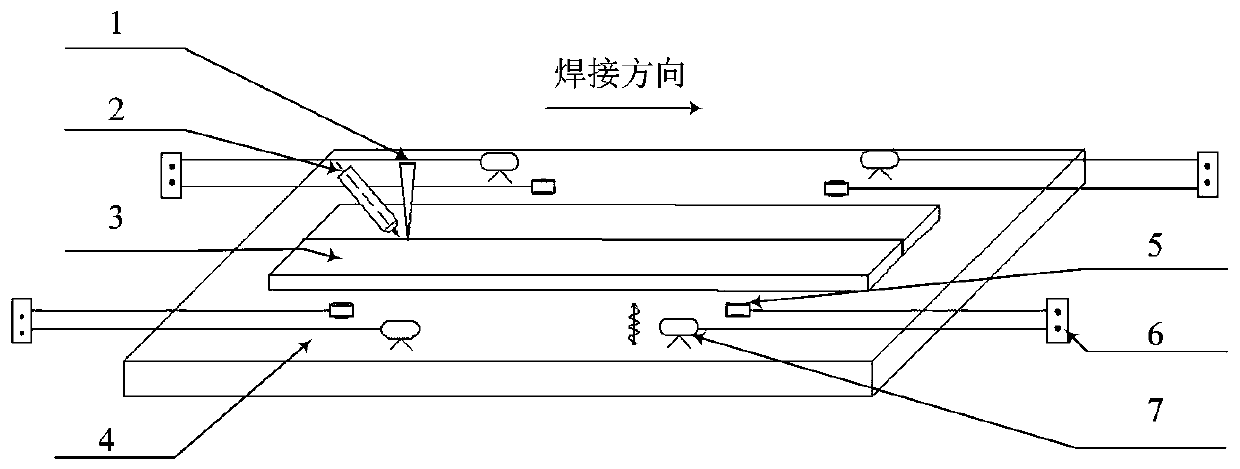

[0040] see figure 1 and figure 2 As shown, Embodiment 1 of the present invention provides a kind of laser CMT composite welding system, comprises welding tooling platform 4, laser device 1, CMT welding torch 2 and exciter 7; Fix workpiece 3 to be welded on described welding tooling platform 4, relatively A weld seam is formed between the adjacent workpieces 3 to be welded, there is a gap between the laser 1 and the CMT welding torch 2 and they are all arranged at the weld seam, the laser produced by the laser 1 and the CMT welding torch 2. The generated welding arc acts together on the weld to form a molten pool. The vibrator 7 is used to provide mechanical vibration, and the vibration generated by it is transmitted to the molten pool to promote the gas in the molten pool to discharge.

[0041] It should be noted that, in this embodiment, "weld seam" refers to the gap formed between adjacent workpieces 3 to be welded without welding.

[0042] In this embodiment, the vibrat...

Embodiment 2

[0052] Such as figure 1 and figure 2 As shown, Embodiment 2 of the present invention provides a welding method using a laser CMT hybrid welding system, which may specifically include the following steps:

[0053] Step 1, before welding, the workpiece 3 to be welded can be wiped with acetone or the like to remove surface oil, and the surface oxide film is removed by mechanical grinding with a wire wheel until the metallic luster is exposed, and the processed workpiece 3 to be welded is fixed on the welding tooling platform 4;

[0054] Step 2, fix the vibrator 7 at a suitable position on the welding tooling platform 4 or the workpiece 3 to be welded, and at the same time, paste the acceleration sensor 5 on the position near the vibrator 7 through an adhesive to detect and ensure that the vibrator 7 For the stability of the system work, the surface where the acceleration sensor 5 is installed should be smooth and smooth to ensure that the acceleration sensor 5 has no obvious sh...

Embodiment 3

[0068] Embodiment 3 of the present invention also provides an aluminum alloy vehicle body welding component, which at least includes a first workpiece and a second workpiece, and the first workpiece and the second workpiece are welded together by the above-mentioned welding method, that is, using The above-mentioned laser CMT hybrid welding method welds the weld seam formed between the first workpiece and the second workpiece, and welds the first workpiece and the second workpiece as a whole. It can greatly reduce or even eliminate the pores generated in the welding process, can ensure the welding quality of aluminum alloy car body welding components, and improve the structure and performance of welded joints.

[0069] The embodiment of the present invention takes the application of laser CMT composite welding technology on the high-speed train car body, especially the aluminum alloy car body as an example. It can be understood that MIG welding, TIG welding and plasma arc weldi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com