Organosilicon-modified acrylate emulsion and preparation method thereof, heat transfer printing back coating liquid, heat transfer printing carbon ribbon back coating and carbon ribbon

An acrylate and silicone technology, used in coating, printing, ink ribbon, etc., can solve the problems of inability to meet the transfer process, poor adhesion performance of substrates, short service life, etc., to facilitate large-scale production, durable The effect of good thermal and slip properties and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

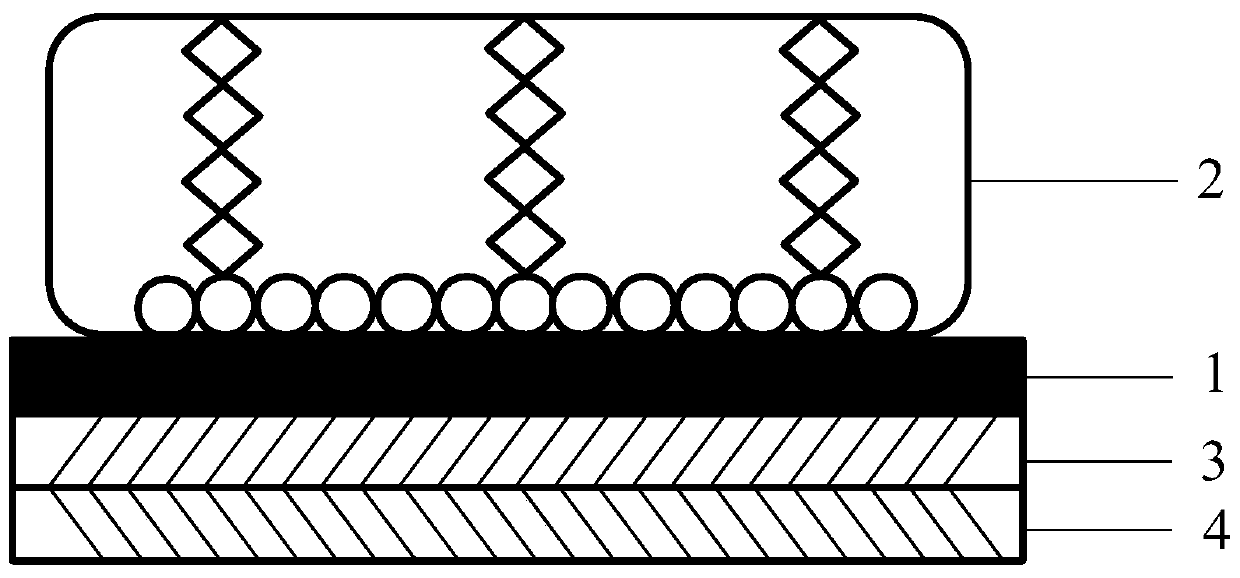

Image

Examples

preparation example Construction

[0088] According to the second aspect of the present invention, the present invention provides the preparation method of the above-mentioned organosilicon-modified acrylate emulsion, comprising the following steps: dissolving the acrylate monomer and the organosilicon-modified acrylate active monomer in a solvent, and then adding The initiator, the acrylate monomer and the organosilicon-modified acrylate active monomer are polymerized to obtain the organosilicon-modified acrylate emulsion.

[0089] The organosilicon-modified acrylate emulsion provided by the invention has simple preparation process, convenient operation, facilitates large-scale production, and reduces preparation cost.

[0090] In a preferred embodiment of the present invention, the acrylate monomer and the organically modified acrylic oligomer are dissolved in a solvent, heated to 30-35°C, and then an initiator is added to further improve the polymerization efficiency and shorten the polymerization time .

...

Embodiment 1

[0112] This embodiment provides a silicone-modified acrylate emulsion, the raw materials of which include the following raw materials in parts by mass: 60 parts of acrylate monomers, 40 parts of silicone-modified acrylate active monomers, diphenyl peroxide 0.3 parts of formyl (BPO), wherein the molecular formula of silicone modified acrylate is R 1 -Si(CH 3 ) 2 -(O-Si(CH 3 ) 2 ) n -O-Si(CH 3 ) 2 -OCO-C(CH 3 )=CH 2 , the number average molecular weight is 10000, R 1 is n-butyl, R 2 It is a propyl group, and the acrylate monomer is a mixture of methyl methacrylate and butyl acrylate, and the mass ratio of the two is 65:8.

Embodiment 2

[0114] This embodiment provides a silicone-modified acrylate emulsion, the raw materials of which include the following raw materials in parts by mass: 80 parts of acrylate monomers, 20 parts of silicone-modified acrylate active monomers, diphenyl peroxide 0.3 parts of formyl, wherein the silicone-modified acrylate and the acrylate monomer are the same as those in Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coating amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com