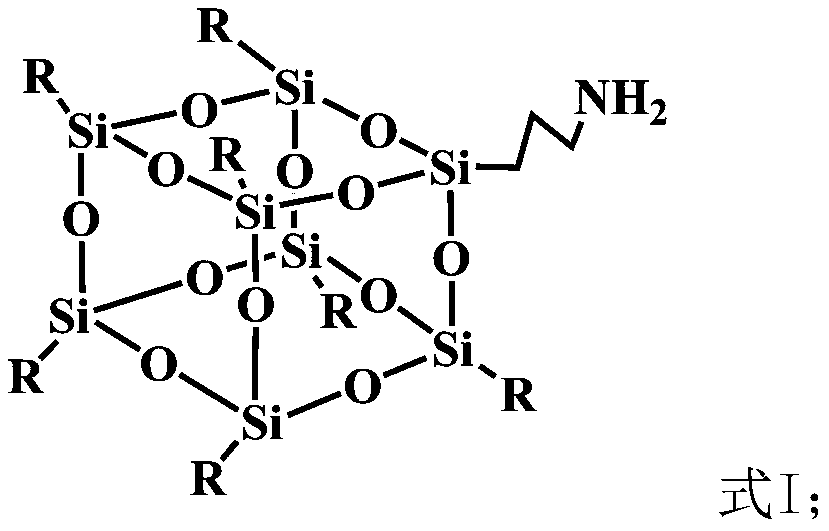

Polyurethane thermoplastic elastomer modified by amino POSS and preparation method of thermoplastic elastomer

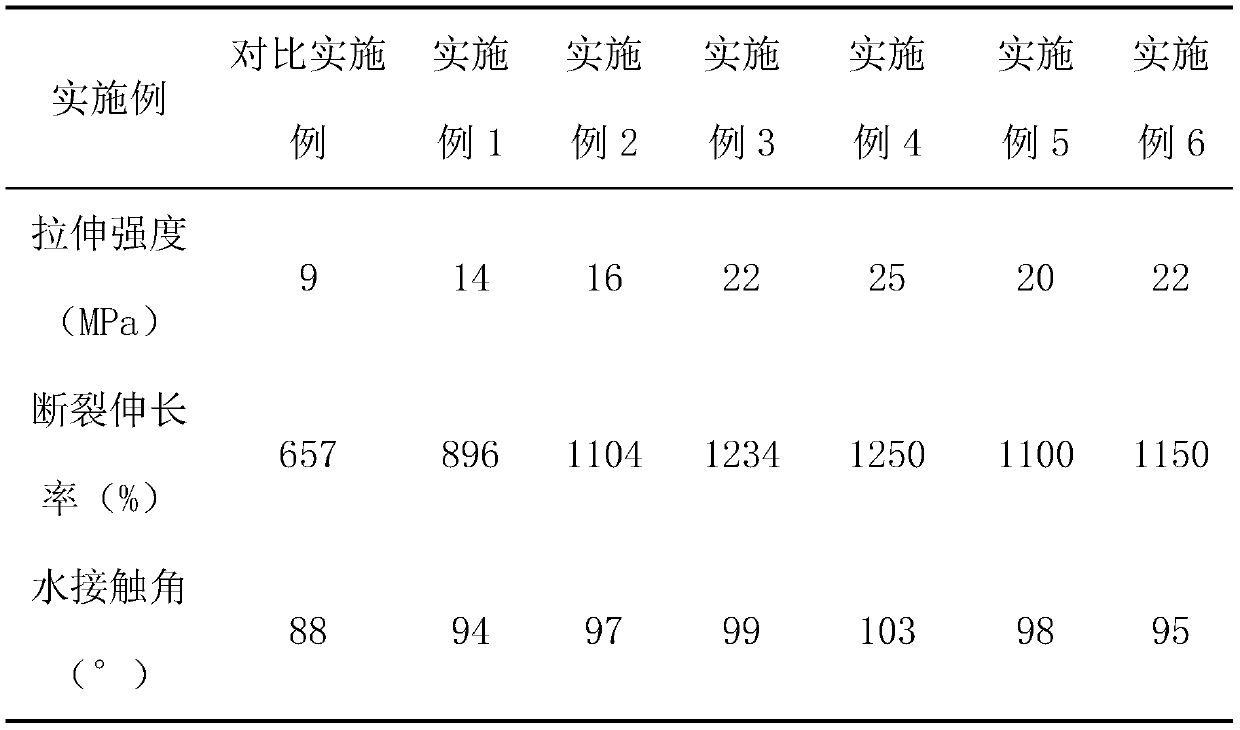

A thermoplastic elastomer and polyurethane technology, applied in the field of amino-POSS modified polyurethane thermoplastic elastomer and its preparation, can solve the problems of poor compatibility between POSS and polyurethane, unfavorable long-life use of materials, low dielectric constant, etc. The effect of improving surface hydrophobicity, improving elongation at break, increasing tensile strength and elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] First weigh each component by the following parts by weight:

[0037] Amino POSS: 1 part;

[0038] Isophorone diisocyanate: 50 parts;

[0039] Polytetrahydrofuran: 30 parts;

[0040] Dibutyltin dilaurate: 0.1 part;

[0041] Acetone: 100 parts;

[0042] Then in high purity N 2 Under protection, dissolve the water-removing polytetrahydrofuran PTMG in dry acetone, stir well, add the catalyst dibutyltin dilaurate and heat to a slight boil.

[0043] Then slowly add isophorone diisocyanate IPDI, reflux reaction for 3 hours, add amino POSS, continue to react for 1 hour and then stop heating;

[0044] The resulting emulsion was left to stand at room temperature until there were no obvious bubbles, then slowly poured into a polytetrafluoroethylene mold, and left to stand at room temperature for 1 day to obtain the amino POSS-modified polyurethane thermoplastic elastomer material.

Embodiment 2

[0046] First weigh each component by the following parts by weight:

[0047] Amino POSS: 4 parts;

[0048] Isophorone diisocyanate: 50 parts;

[0049] Polytetrahydrofuran: 30 parts;

[0050] Dibutyltin dilaurate: 0.1 part;

[0051] Acetone: 105 parts;

[0052] Then in high purity N 2 Under protection, dissolve the water-removing polytetrahydrofuran PTMG in dry acetone, stir well, add the catalyst dibutyltin dilaurate and heat to a slight boil;

[0053] Then slowly add isophorone diisocyanate IPDI, reflux reaction for 4 hours, add amino POSS, continue to react for 1 hour, then stop heating;

[0054] The resulting emulsion was left to stand at room temperature until there were no obvious bubbles, then slowly poured into a polytetrafluoroethylene mold, and left to stand at room temperature for 1 day to obtain the amino POSS-modified polyurethane thermoplastic elastomer material.

Embodiment 3

[0056] First weigh each component by the following parts by weight:

[0057] Amino POSS: 7 parts;

[0058] Isophorone diisocyanate: 50 parts;

[0059] Polytetrahydrofuran: 40 parts;

[0060] Dibutyltin dilaurate: 0.1 part;

[0061] Acetone: 110 parts;

[0062] Then in high purity N 2 Under protection, dissolve the water-removing polytetrahydrofuran PTMG in dry acetone, stir well, add the catalyst dibutyltin dilaurate and heat to a slight boil;

[0063] Then slowly add isophorone diisocyanate IPDI, reflux reaction for 5 hours, add amino POSS, continue to react for 1 hour and stop heating;

[0064] The resulting emulsion was left to stand at room temperature until there were no obvious bubbles, then slowly poured into a polytetrafluoroethylene mold, and left to stand at room temperature for 1 day to obtain the amino POSS-modified polyurethane thermoplastic elastomer material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com