Moisture-proof mildew-proof color putty for inner walls

A color and putty technology, applied in the direction of filling slurry, etc., can solve the problems of poor moisture resistance, easy to drop powder, easy to crack, etc., and achieve the effect of strong moisture resistance, beautiful effect and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

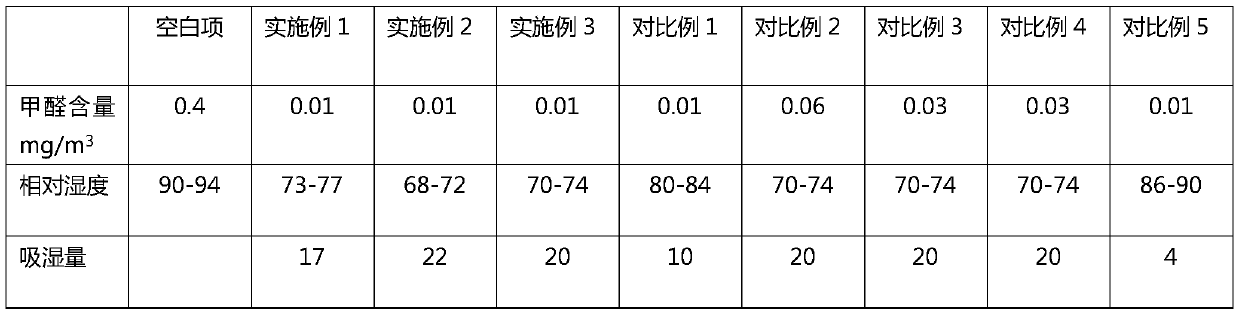

Examples

Embodiment 1

[0027] A kind of moisture-proof mildew-proof colored putty for interior walls of the present embodiment comprises 500 parts of white cement, 500 parts of light calcium carbonate, 10 parts of wood calcium, 6 parts of dry powder anti-mold agent, 3 parts of dispersant, and 50 parts of colored stone powder. 15 parts of redispersible rubber powder, 2 parts of starch ether, 5 parts of cellulose ether, 15 parts of xanthan gum, 20 parts of nano titanium dioxide, 10 parts of activated carbon, 10 parts of zeolite, 2 parts of graphene, 8 parts of super absorbent resin, ion Exchange resin 4 parts.

Embodiment 2

[0029] A kind of moisture-proof mildew-proof colored putty for interior walls of the present embodiment comprises 600 parts of white cement, 400 parts of talcum powder, 3 parts of wood calcium, 4 parts of dry powder anti-mold agent, 2 parts of dispersant, 30 parts of colored stone powder, and can be redispersed 10 parts of rubber powder, 1 part of starch ether, 3 parts of cellulose ether, 10 parts of xanthan gum, 10 parts of nano titanium dioxide, 5 parts of activated carbon, 5 parts of zeolite, 1 part of graphene, 12 parts of super absorbent resin, ion exchange resin 10 servings.

Embodiment 3

[0031] A kind of moisture-proof mildew-proof color putty for inner wall of the present embodiment comprises 550 parts of white cement, 450 parts of heavy calcium carbonate, 6 parts of wood calcium, 5 parts of dry powder anti-mold agent, 2 parts of dispersant, 40 parts of colored stone powder, can 13 parts of redispersible rubber powder, 1.5 parts of starch ether, 4 parts of cellulose ether, 13 parts of xanthan gum, 15 parts of nano titanium dioxide, 7 parts of activated carbon, 7 parts of zeolite, 1.5 parts of graphene, 10 parts of super absorbent resin, ion Exchange resin 7 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com