Composition for regulating high-alkali coal, regulating method and application

A high-alkali coal and composition technology, applied in the field of coal ash chemistry, can solve the problems of ash on the surface of the equipment and the poor slag hanging effect of the water-cooled wall, and achieve the goal of reducing the amount, reducing the difficulty and labor intensity of production operations, and expanding the scope of application. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

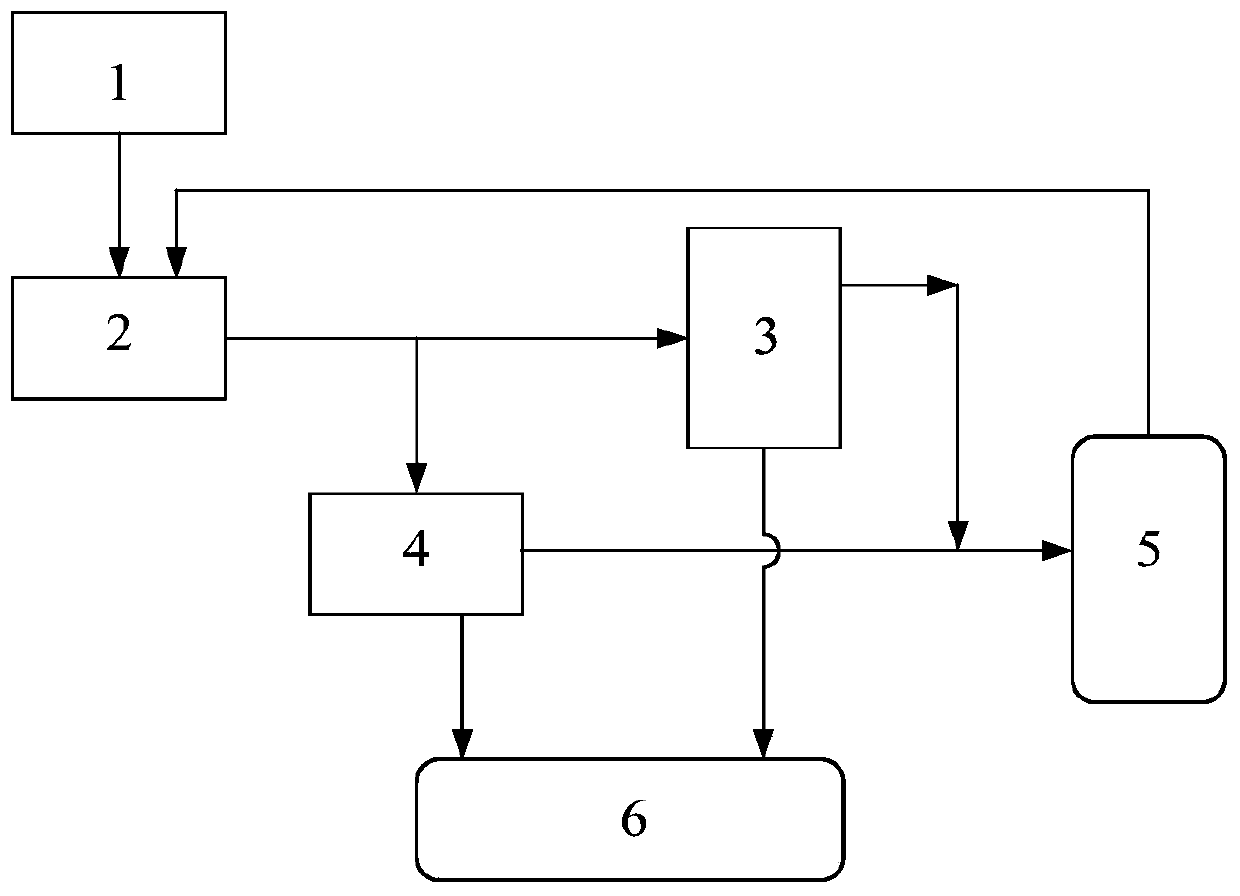

[0042] Such as figure 1 As shown, the Xinjiang Zhundong high-alkali coal is processed by the high-alkaline raw coal crushing and weighing system 1, and then fully mixed with the fly ash from the by-product fly ash collection system 5 of the project in the ash-increasing and anti-sedimentation agent mixing system 2 And ground into fine coal powder, then sent to the gasification unit 3 and power unit 4 respectively, the fly ash generated after gasification or combustion is sent to the by-product fly ash collection system 5 of the project, and the coal ash is sent to the project By-product coal ash collection system6.

[0043] Regularly sample the fly ash in the by-product fly ash collection system 5 of the project, and check whether the alkali-acid ratio (B / A) in the ash component is ≤0.1, and judge whether the batch of fly ash can be used as ash increasing Depressants.

[0044] If the test finds that the fly ash by-product of the project has an alkali-acid ratio (B / A) > 0.1, it...

Embodiment 2

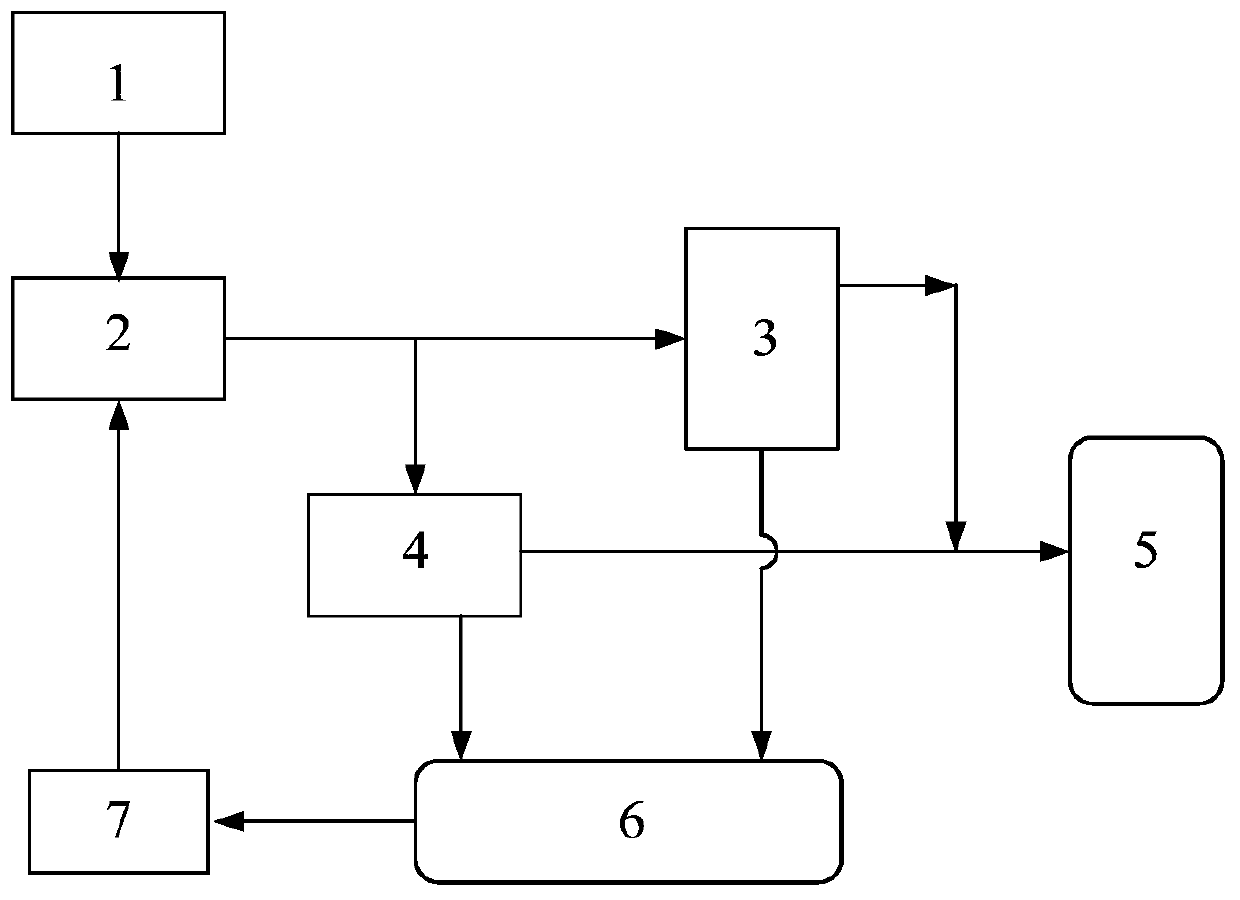

[0046] Such as figure 2 As shown, Xinjiang Zhundong high-alkali coal is processed by the high-alkaline raw coal crushing and weighing system 1, and then fully mixed with the coal ash from the project coal ash crushing and pulverizing system 7 in the ash-increasing and anti-sedimentation agent mixing and pulverizing system 2 And ground into fine coal powder, then sent to the gasification unit 3 and power unit 4 respectively, the fly ash generated after gasification or combustion is sent to the by-product fly ash collection system 5 of the project, and the coal ash is sent to the project By-product coal ash collection system6.

[0047] Regularly sample the coal ash in the by-product coal ash collection system 6, and check whether the alkali-acid ratio (B / A) in the ash component is ≤0.1, so as to judge whether the batch of coal ash can be used to increase ash and suppress sedimentation agent.

[0048] If the test finds that the alkali-acid ratio (B / A) of the coal ash slag prod...

Embodiment 3

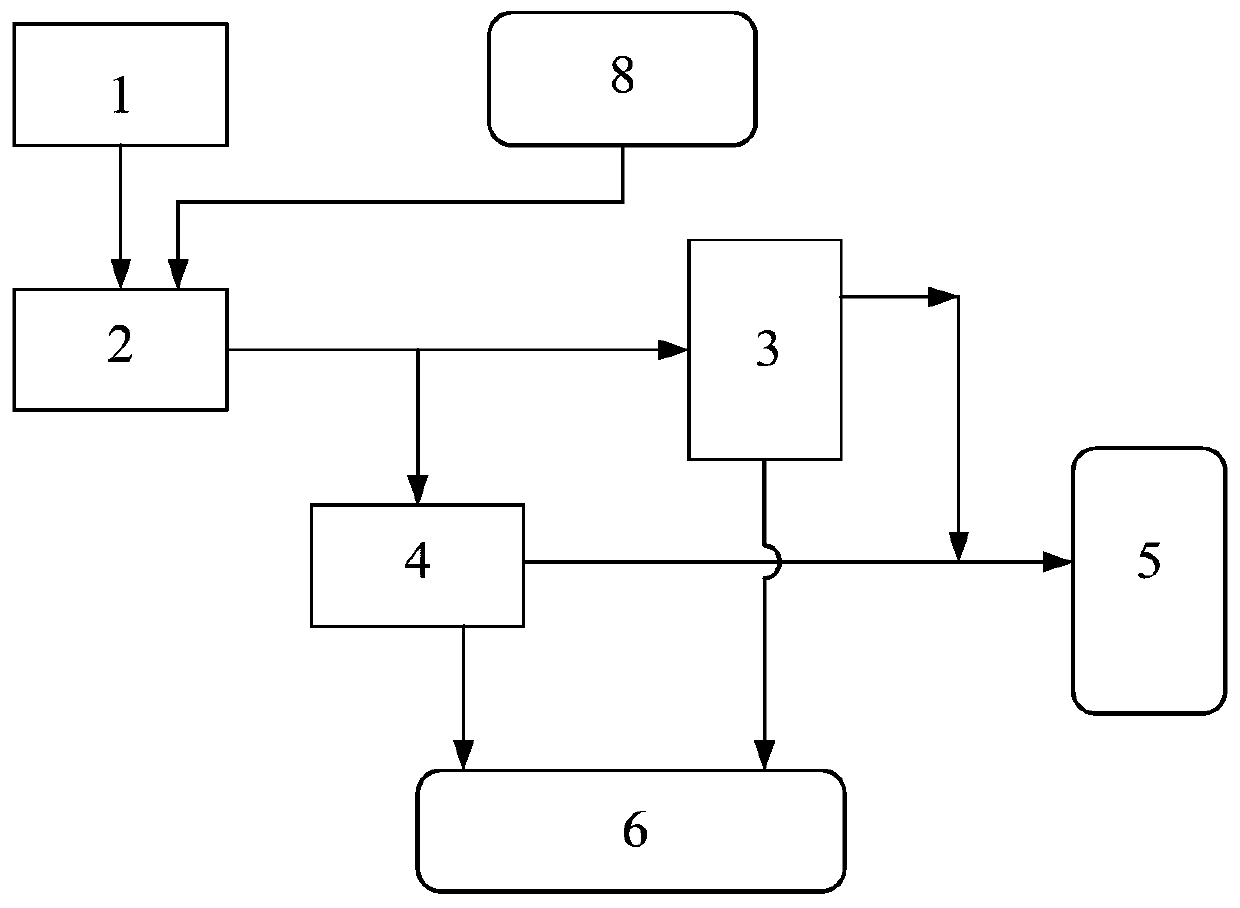

[0050] Such as image 3 As shown, after the Xinjiang Zhundong high-alkaline coal is processed by the high-alkaline raw coal crushing and weighing system 1, it is fully mixed with the fly ash from the purchased ash-increasing and anti-sedimentation agent storage tank 8 in the ash-increasing and anti-sedimentation agent mixing system 2. Mixed and ground into fine coal powder, then sent to the gasification unit 3 and power unit 4 respectively, the fly ash generated after gasification or combustion is sent to the by-product fly ash collection system 5 of the project, and the coal ash is sent to the Project by-product coal ash collection system 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com