Marine cable aging performance testing method

A test method and technology for marine cables, which are applied in the field of cables, can solve problems such as cable insulation damage, failure to evaluate and judge the cable insulation state, and insulation layer aging, so as to avoid accidents and safety hazards and improve the safe and stable operation of ships.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

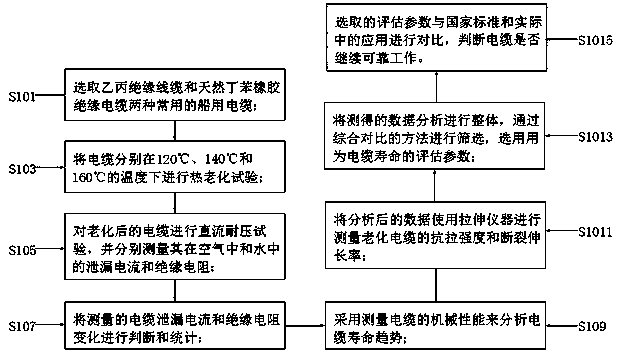

[0028] Embodiment one, such as figure 1 As shown, a method for testing the aging performance of a marine cable according to an embodiment of the present invention includes a DC comparison method, a direct reading method and a megger method, and specifically includes the following steps:

[0029] Step S101, selecting two commonly used marine cables, ethylene-propylene insulated cables and natural styrene-butadiene rubber insulated cables;

[0030] Step S103, performing thermal aging tests on the cables at temperatures of 120°C, 140°C and 160°C respectively;

[0031] Step S105, performing a DC withstand voltage test on the aged cable, and measuring its leakage current and insulation resistance in air and water respectively;

[0032] Step S107, judging and counting the measured cable leakage current and insulation resistance changes;

[0033] Step S109, analyzing the cable life trend by measuring the mechanical properties of the cable;

[0034] Step S1011, using a tensile inst...

Embodiment 2

[0037] Embodiment 2, the temperature of the test field during the measurement is 16° C., and the humidity is 30-60%.

Embodiment 3

[0038] Embodiment 3, the trend of the elongation at break is mathematically fitted using an exponential function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com