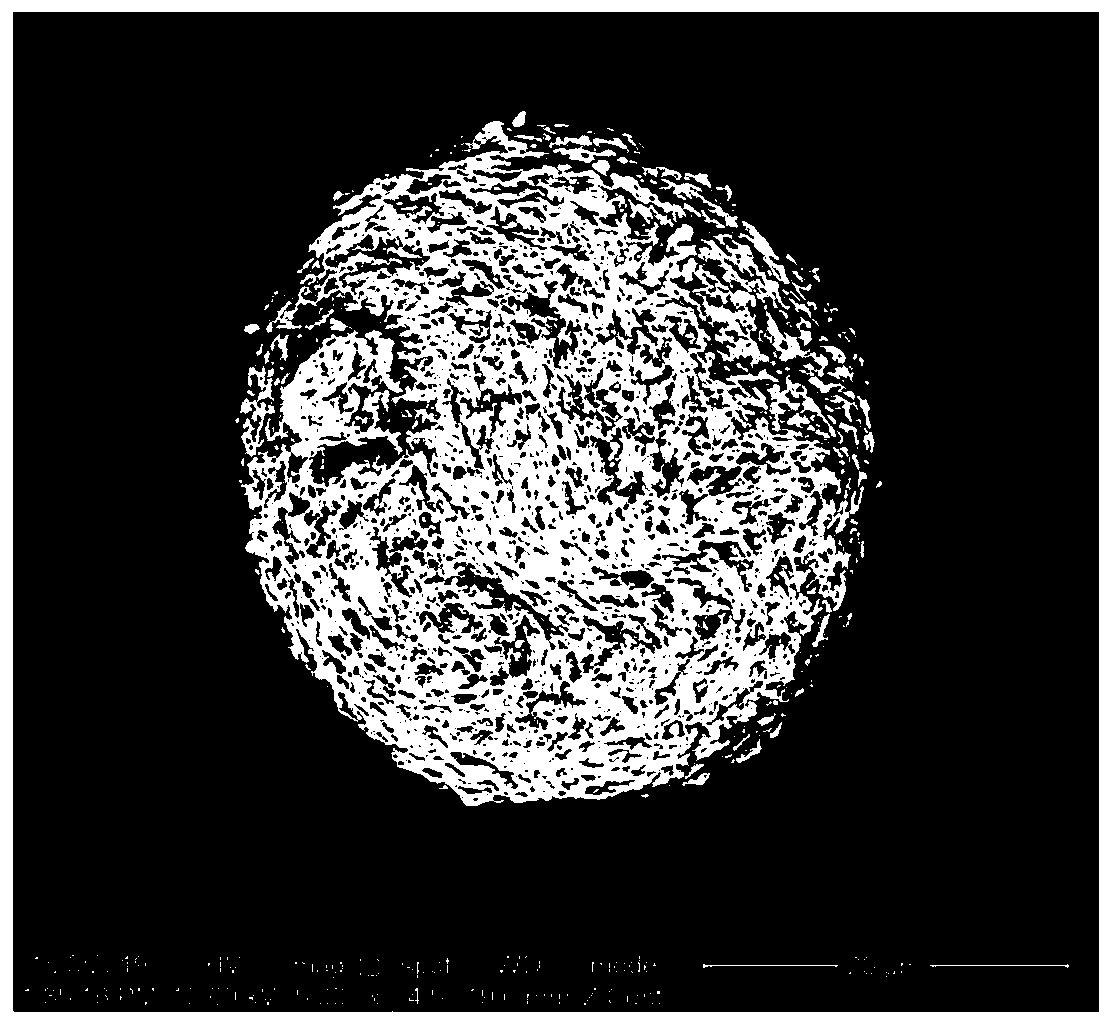

Preparation method of attapulgite balls for adsorption of radioactive nuclides and heavy metal ions

A technology for heavy metal ions and radionuclides, which is applied in the field of preparation of attapulgite pellets, can solve the problems of inconvenient maintenance of centrifuges, easy blockage of liquid phase discharge, and difficulty in scraping and cleaning, and achieves easy solid-liquid separation and improved adsorption energy. , the effect of less synthetic raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027]The preparation method of the attapulgite ball which adsorbs radionuclides and heavy metal ions comprises the following steps:

[0028] (1) Put pure attapulgite in a volumetric flask, then add hydrochloric acid with a concentration of 1-7% in mass fraction, plug the bottle stopper and place it in an oven at 50-80°C for 12-24h activation, after washing at 85 Dry at -105°C for 1-2 hours;

[0029] (2) Place the dried acidified attapulgite powder obtained in step (1) in a high-temperature furnace, and roast at 300-600°C for 1-2h;

[0030] (3) Using isopropanol as the grinding medium, the attapulgite powder obtained in step (2) and alumina grinding balls are mixed by high-energy ball milling, and the mass ratio of the grinding balls to the material is 1:1.5-3.5; grinding The mass ratio of medium and material is 1:2-4, the ball milling rate is 1000-4000r / min, after the ball milling is completed, the obtained slurry is dried for 24 hours to constant weight, ground and sieved t...

Embodiment 1

[0037] The preparation method of the attapulgite ball which adsorbs radionuclides and heavy metal ions adopts the following steps:

[0038] (1) Put pure attapulgite in a volumetric flask, add hydrochloric acid with a mass concentration of 7%, stopper the bottle, place it in an oven at 70°C for 24 hours, and finally wash and dry it. The drying treatment is to burn at 105°C for 1.5h.

[0039] (2) Put the dried acidified attapulgite powder obtained in step (1) in a high-temperature furnace, and bake at 400° C. for 2 hours.

[0040] (3) Using isopropanol as the grinding medium, the attapulgite powder obtained in step (2) and alumina balls are mixed by means of high-energy ball milling. The ball milling rate is 1500r / min. After the ball milling is completed, the obtained slurry Dry for 24 hours to constant weight, grind and sieve to obtain finely ground attapulgite powder.

[0041] (4) Put the powder obtained in step (3) into N-methyl-1-pyrrolidone to stir and disperse, and then ...

Embodiment 2

[0048] The preparation method of the attapulgite ball which adsorbs radionuclides and heavy metal ions adopts the following steps:

[0049] (1) Put pure attapulgite in a volumetric flask, then add hydrochloric acid with a concentration of 5% by mass fraction, cork the bottle, place it in an oven at 60°C for 18 hours, and finally wash and dry it. The drying process is to burn at 100°C for 2h.

[0050] (2) Put the dried acidified attapulgite powder obtained in step (1) in a high-temperature furnace, and bake at 600° C. for 1.5 h.

[0051] (3) Using isopropanol as the grinding medium, the attapulgite powder obtained in step (2) and alumina balls are mixed by high-energy ball milling. The ball milling rate is 2000r / min. After the ball milling, the obtained slurry is Dry for 24 hours to constant weight, grind and sieve to obtain finely ground attapulgite powder.

[0052] (4) Put the powder obtained in step (3) into N-methyl-1-pyrrolidone to stir and disperse, then put it into an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com