Diffuse type sulfur burner

A sulfur incinerator, diffusion type technology, applied in the direction of sulfur compounds, inorganic chemistry, non-metallic elements, etc., can solve the problems of increasing system resistance capacity, high material consumption, increasing energy consumption, etc., to reduce airflow velocity and increase residence time. , the effect of increasing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

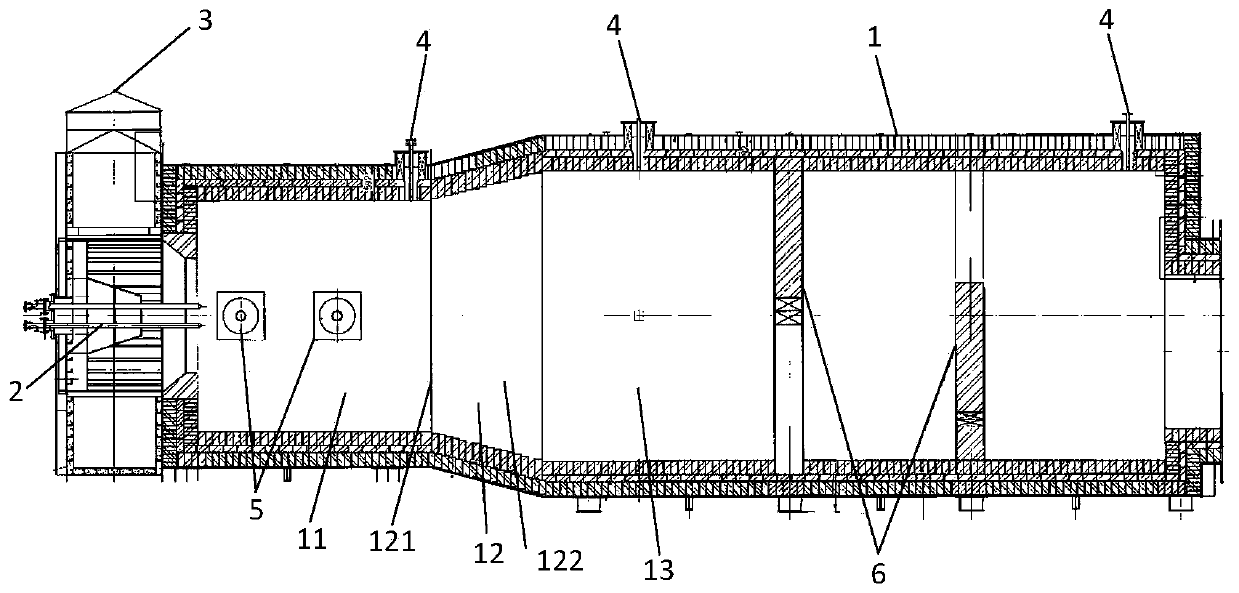

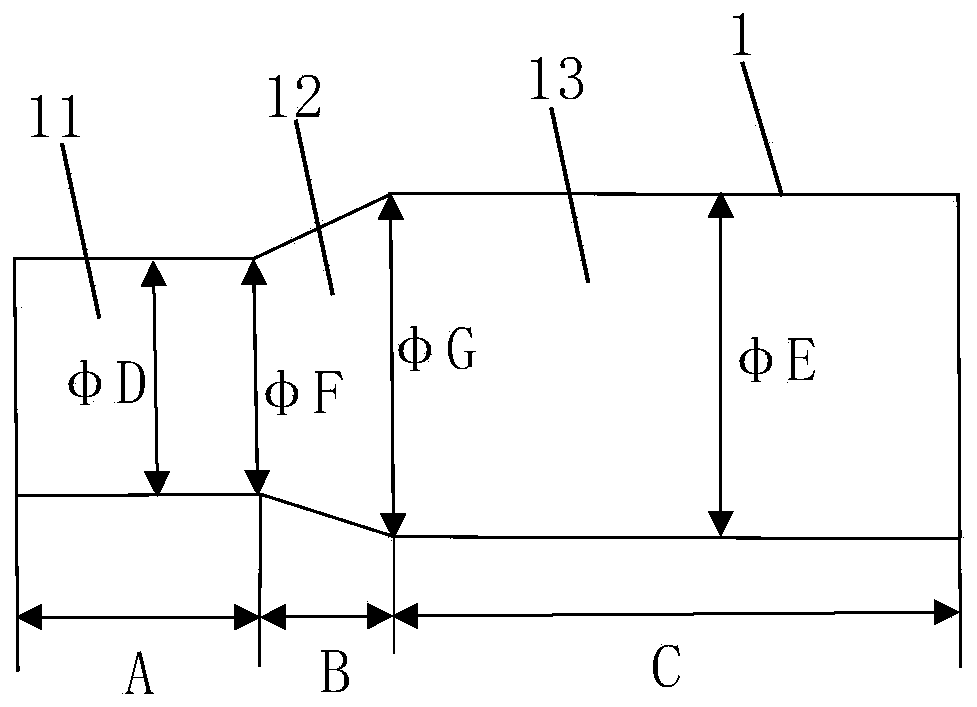

[0025] Fujian Shenyuan New Materials Co., Ltd. built a new 400,000-ton sulfuric acid plant and used this new diffusion type sulfur incinerator. The specific structural dimensions of the sulfur incinerator are as follows: the lengths of the front section of the combustion chamber, the reducing connection chamber and the rear section of the combustion chamber are 4.640 meters, 1.872 meters and 11.041 meters respectively; the inner diameters of the front section of the combustion chamber and the rear section of the combustion chamber are 5.084 meters and 6.084 meters.

[0026] It was put into production in July 2017. The sulfur incinerator has been in good condition for nearly two years of operation, the liquid sulfur is fully burned, and the equipment operates stably. During the overhaul in April 2019, no sublimated sulfur was found in the equipment pipeline inspection.

[0027] To sum up, the sulfur incinerator of the present invention adopts a diffused burner design, the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com