Thermal conductive pole piece and preparation method and use thereof

A pole piece and thermally conductive coating technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, structural parts, etc., can solve problems such as affecting the heat dissipation effect of the pole piece, and achieve improved heat dissipation effect, strong manufacturability, and thermal conductivity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

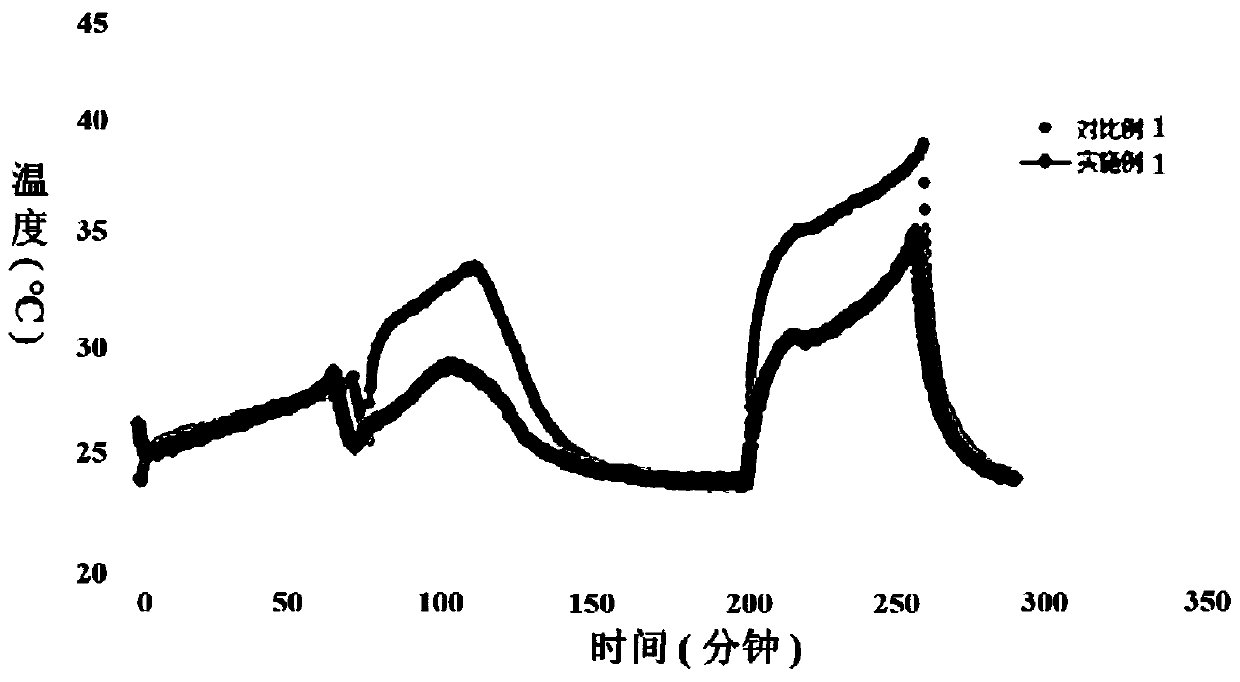

Embodiment 1

[0070] A method for preparing a thermally conductive pole piece comprises the steps of:

[0071] (1) Mix 0.6g silane coupling agent, 0.6g epoxy resin and 100g NMP at 1200rmp for 2h, then add 2.2g multi-walled carbon nanotubes (length is 2μm, diameter is 10nm, aspect ratio is 200) Sand milling and mixing for 1 hour to obtain a thermally conductive slurry with a viscosity of 220mPa.s;

[0072] (2) The heat-conducting slurry is gravure-coated on both sides of the positive electrode sheet respectively, and the side with a positive active material coverage rate of 92% is designated as the A side, and the side with a positive active material coverage rate of 80% is designated as the B side, The thickness of the thermally conductive coating on side A is 1 μm, and the surface density is 0.08 mg / cm 2 , the thickness of the B-side thermally conductive coating is 1 μm, and the surface density is 0.08 mg / cm 2 , dried at 120°C, tape running speed at 1m / min, and cold pressed at 210T press...

Embodiment 2

[0074] The difference from Example 1 is that the multi-walled carbon nanotubes in step (1) are replaced by an equal amount of graphene, and the size of the graphene is 5 μm.

Embodiment 3

[0076] The difference from Example 1 is that the multi-walled carbon nanotubes in step (1) are replaced by an equal amount of graphene, and the size of the graphene is 1 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com