Method for processing brown rice noodles by baking and pretreating rice bran

A pretreatment and rice bran technology, applied in the direction of food science, etc., can solve the problems of short shelf life, poor taste, easy oxidation and rancidity of brown rice vermicelli, and achieve the effects of convenient storage and transportation, reducing hardness, and expanding product production and sales channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

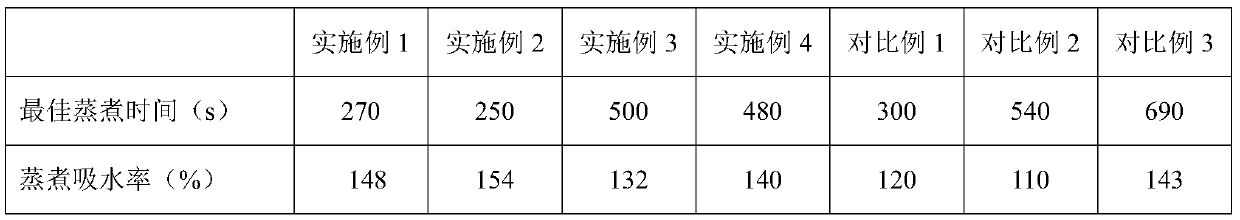

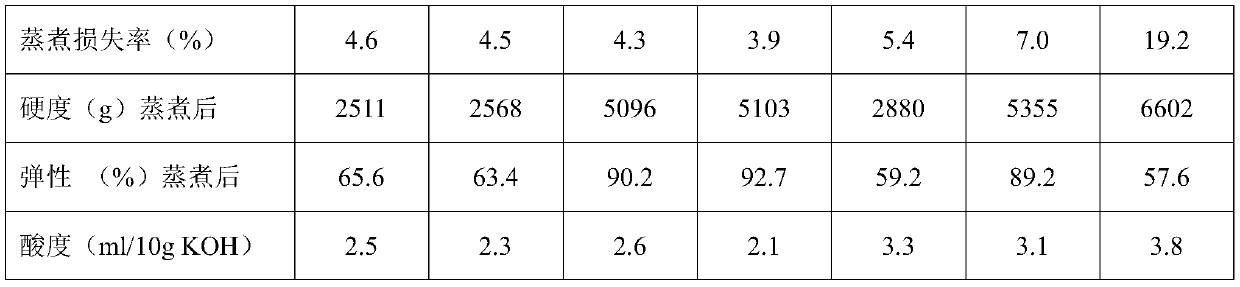

Examples

Embodiment 1

[0040] Select indica brown rice, remove floating ash and mixed gravel and other sundries, wash with pure water, and grind to obtain rice bran and white rice. The rice bran was roasted at a roasting temperature of 200° C. for 10 minutes. After the rice bran is cooled, soak the rice bran and water at a ratio of 1:2 for 2 hours, and use a colloid mill to grind the rice bran to control the particle size range of 200-300 μm. Soak the white rice and water at a ratio of 1:2 for 2 hours, then grind it with a stone mill, and control the particle size range of the white rice flour to 200-300 μm. Then the rice bran slurry and the white rice slurry are uniformly mixed, ground by a stone mill, and the particle size range of the rice bran and white rice flour in the slurry is controlled to be 100-200 μm. Monitor the concentration of the mixed slurry with a Baume meter, adjust the concentration of the mixed slurry to be about 25 Baume degrees, spread the mixed slurry into thin slices, and s...

Embodiment 2

[0042]Select indica brown rice, remove floating ash and mixed gravel and other sundries, wash with pure water, and grind to obtain rice bran and white rice. The rice bran was roasted at a roasting temperature of 150° C. for 20 minutes. After the rice bran is cooled, soak the rice bran and water at a ratio of 1:4 for 6 hours, and use a colloid mill to grind the rice bran to control the particle size range of 200-300 μm. Soak the white rice and water at a ratio of 1:4 for 6 hours, then grind it with a stone mill, and control the particle size range of the white rice flour to 200-300 μm. Then the rice bran slurry and the white rice slurry are uniformly mixed, ground by a stone mill, and the particle size range of the rice bran and white rice flour in the slurry is controlled to be 100-200 μm. Monitor the concentration of the mixed slurry with a Baume meter, adjust the concentration of the mixed slurry to be about 15 Baume degrees, spread the mixed slurry into thin slices, and st...

Embodiment 3

[0044] Weigh the early indica brown rice, wash it with pure water, remove floating ash and mixed gravel and other sundries. Brown rice is milled to obtain rice bran and white rice. The rice bran was roasted at a roasting temperature of 220° C. for 5 minutes. Grind the white rice to a particle size of 30-50 μm. The roasted rice bran is crushed to a particle size of 30-50 μm, and mixed with white rice flour to form brown rice flour. Adjust the water content of the brown rice flour to between 35-40%, and wet it under normal temperature for 8 hours. The brown rice flour is extruded and matured into strips in a single-screw self-cooking machine, and extruded in a wire extruder. Aging in 20°C incubator for 4h; re-steaming at 80°C for 3h. Dry in a hanging dryer at a temperature of 50°C for 1 hour. The dried brown rice noodles are collected, cut to length, and bagged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com