Edible oil locking preservation method

A fresh-keeping method and edible oil technology, applied in the direction of using additives to preserve fatty substances, using back pressure perfusion, bottle perfusion, etc., can solve the problems of increasing the cost of natural antioxidants, achieve the effect of improving oxidation stability and solving oxidative rancidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

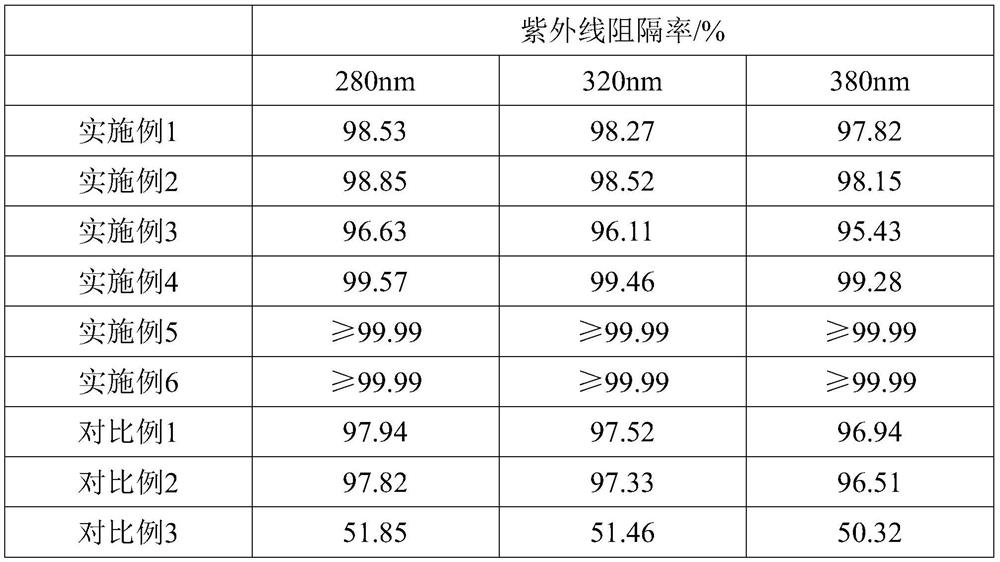

Embodiment 1

[0030] A rapeseed oil locking preservation method, including natural antioxidants, filled with nitrogen filled and ultraviolet bottle packaging.

[0031] Natural antioxidants are tea polyphenols, and the amount of food is 0.1 g / kg.

[0032] The nitrogen filling includes nitrogen-filled oil storage tanks, nitrogen purge oil pipes and packaging bottles, and filled nitrogen seals, nitrogen purity ≥99.9%, nitrogen seal bottle internal endspace residual content of 2.5% .

[0033] Synthesis of polyethylene terephthalate: 166 g of terephthalic acid, 65 g of ethylene glycol, and ethylene glycol titanium (10 ppm of titanium titanate) is added to the polymerization kettle (10 ppm of terephthalic acid), at temperature 230 ° C, pressure 0.2 MPa was esterified for 3 h, evacuated, and the polymerization was polymerized at a temperature of 270 ° C, and the polymerization of polyethylene terephthalate was obtained.

[0034] Preparation of UV-UV mother particles: The polyethylene terephthalate p...

Embodiment 2

[0037] A soybean oil locking preservation method, including natural antioxidants added, nitrogen filled and ultraviolet bottle packaging.

[0038] Natural antioxidants are vitamin E, which is added to 0.2 g / kg.

[0039] Filling filling includes nitrogen-filled oil tanks before filling, nitrogen purge oil pipeline and packaging bottle and filled nitrogen seal, nitrogen purity ≥99.9%, nitrogen seal in the bottle of nitrogen seal is 2.0%. .

[0040] Synthesis of polyethylene terephthalate: 166 g of terephthalic acid, 72 g of ethylene glycol and ethylene glycol titanium (10 ppm of titanium titanate), 10 ppm of phenylene terephthalic acid, pressure at temperature 230 ° C, pressure 0.2 MPa was esterified for 3 h, evacuated, and the polymerization was polymerized at a temperature of 270 ° C, and the polymerization of polyethylene terephthalate was obtained.

[0041] Preparation of UV-UV mother particles: The polyethylene terephthalate prepared polyethylene terephthalate and the UV extr...

Embodiment 3

[0044]A corn oil locking preservation method, including natural antioxidants, filled with nitrogen filled and ultraviolet bottle packaging.

[0045] Natural antioxidants are sesame phenol and add amount of 0.05 g / kg.

[0046] The nitrogen-filled filling includes nitrogen-filled oil storage tanks, nitrogen purge oil pipes and packaging bottles and filled nitrogen seals, nitrogen purity ≥99.9%, nitrogen seal bottle internal end-empty endonal residue content is 1.5% .

[0047] Synthesis of polyethylene terephthalate: 166 g of terephthalic acid, 85 g of ethylene glycol, and ethylene glycol titanium (10 ppm of titanium titanate), 10 ppm in temperature of 230 ° C, pressure at temperature 230 ° C, pressure 0.2 MPa was esterified for 3 h, evacuated, and the polymerization was polymerized at a temperature of 270 ° C, and the polymerization of polyethylene terephthalate was obtained.

[0048] Preparation of UV-UV mother particles: The polyethylene terephthalate prepared polyethylene terep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com