Multifunctional C4F7N/CO2 mixed gas distribution system and method

A C4F7N, mixed gas technology, used in mixing methods, gas and gas/vapor mixing, organic gas insulators, etc., can solve the problems of slow vaporization, unable to quickly prepare mixed gas, etc., to ensure stability and improve gas distribution rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

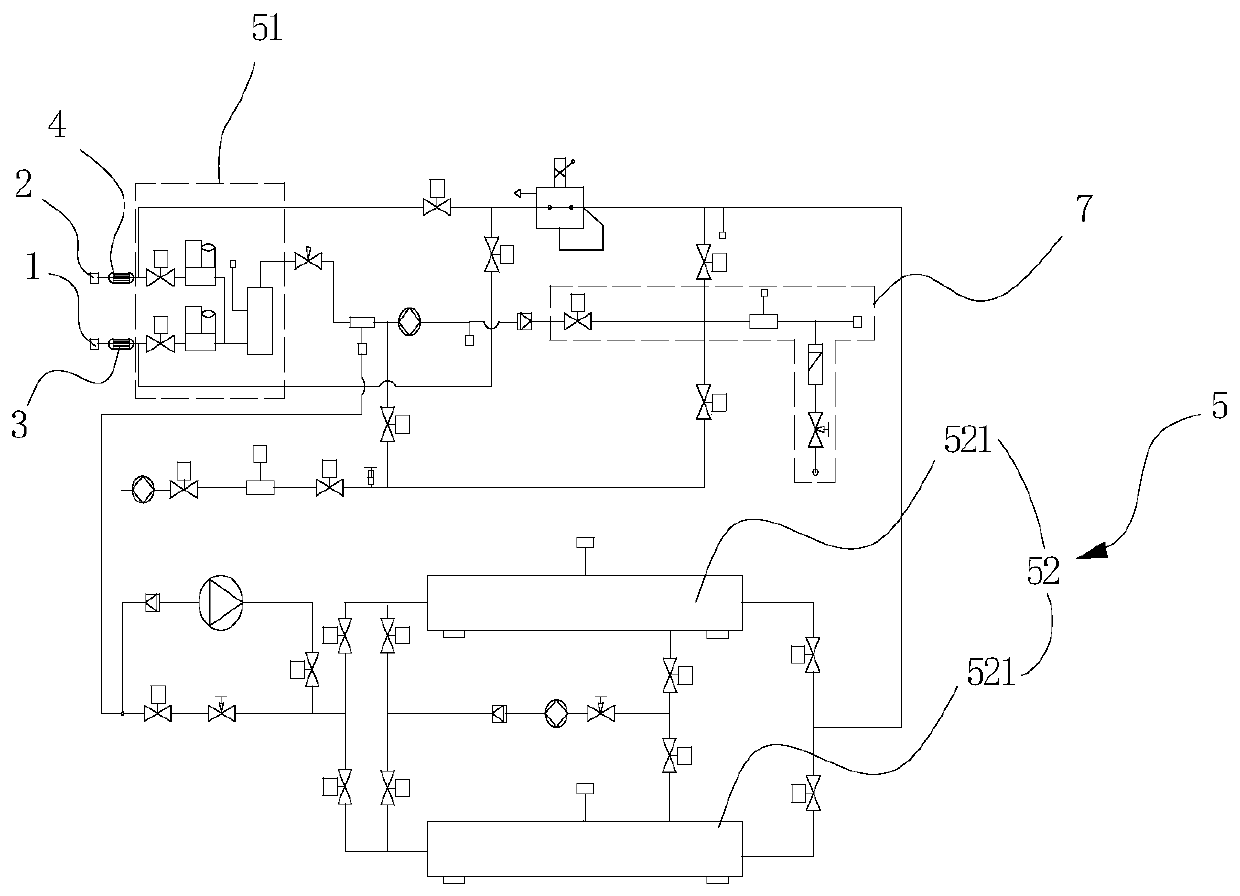

[0064] Such as figure 1 As shown, this embodiment discloses a multifunctional C 4 F 7 N / CO 2 Mixed gas distribution system, including C 4 F 7 N input port 1, CO 2 Input port 2, C 4 F 7 N heat exchanger 3, CO 2 Heat exchanger 4, C 4 F 7 N / CO 2 Mixed pipeline structure 5, C 4 F 7 N / CO 2 Mixed gas output pipeline structure 7.

[0065] C 4 F 7 N heat exchanger 3 is used to align the warp C 4 F 7 N input port 1 input C 4 F 7 N is heated and vaporized. CO 2 Heat exchanger 4 is used to compare CO 2 CO input from input 2 2 Perform heating and vaporization. C 4 F 7 N / CO 2 Mixing pipeline structure 5 is used to control the vaporized C 4 F 7 N, CO 2 To mix, C 4 F 7 N / CO 2 The mixed gas output pipeline structure 7 is used to output the mixed C 4 F 7 N / CO 2 mixed composition.

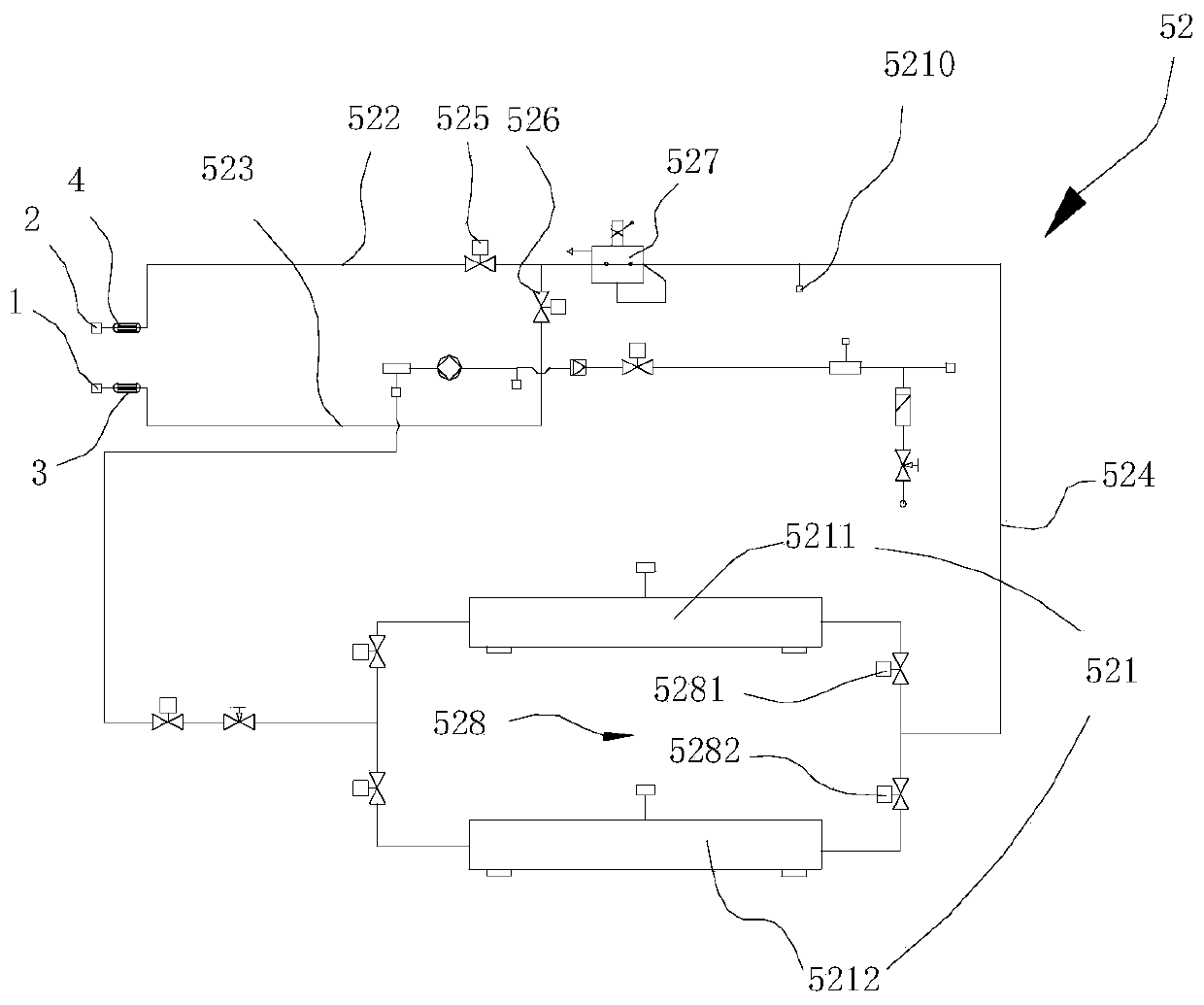

[0066] C 4 F 7 N / CO 2 Hybrid pipeline structure 5 includes C 4 F 7 N / CO 2 Dynamic gas distribution pipeline structure 51, C 4 F 7 N / CO 2 Partial pressure mixing pipeline structure 52.

[0067] C 4 F 7 N / CO 2 Dynamic gas d...

Embodiment 2

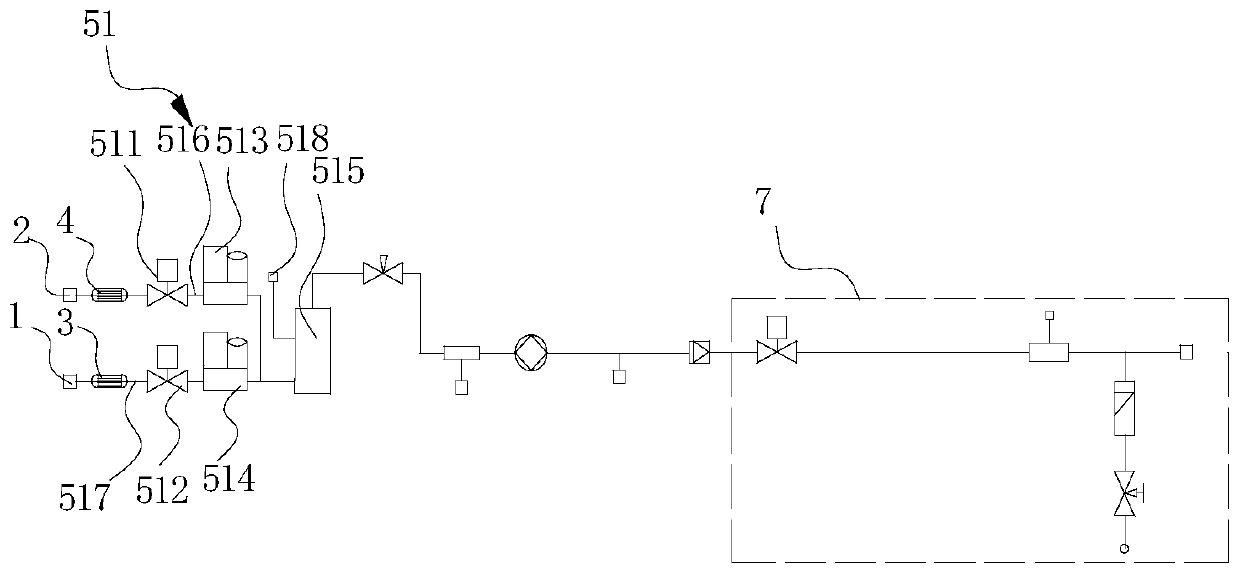

[0073] Such as figure 2 As shown, the difference between this embodiment and the above embodiment is that a specific C 4 F 7 N / CO 2 Dynamic gas distribution pipeline structure 51.

[0074] The C 4 F 7 N / CO 2 The dynamic gas distribution pipeline structure 51 includes a first solenoid valve 511, a second solenoid valve 512, a first thermal mass flow meter 513, a second thermal mass flow meter 514, a buffer mixing tank 515, a first pipe 516, and a second pipe 517.

[0075] The buffer mixing tank 515 is provided with a first air inlet, a second air inlet, and a first mixed gas outlet.

[0076] CO 2 The air outlet of the heat exchanger 4 communicates with the first air inlet through a first pipe 516, and the first solenoid valve 511 and the first thermal mass flow meter 513 are both arranged on the first pipe 516. C 4 F 7 The air outlet of the N heat exchanger 3 communicates with the second air inlet through a second pipe 517, and the second solenoid valve 512 and the second thermal ma...

Embodiment 3

[0080] Such as figure 2 As shown, the difference between this embodiment and the foregoing embodiment is that a first differential pressure sensor 518 is provided on the buffer mixing tank 515. By setting the first differential pressure sensor 518 on the buffer mixing tank 515, the mixed C 4 F 7 N / CO 2 The pressure of the mixed gas is tested to further monitor the accuracy of the mixed gas. Of course, if C 4 F 7 N / CO 2 The pressure value of the mixed gas deviates from the set range, the first differential pressure sensor 518 also sends a signal to the control center, and the control center drives the first solenoid valve 511 and the second solenoid valve 512 to adjust the corresponding opening.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com