Ceramic mold shell for casting single crystal blades and manufacturing method thereof

A technology of ceramic formwork and single crystal blades, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve problems such as casting defects of ceramic formwork, prevent heat from being dissipated downward, reduce energy consumption, and improve temperature gradients Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

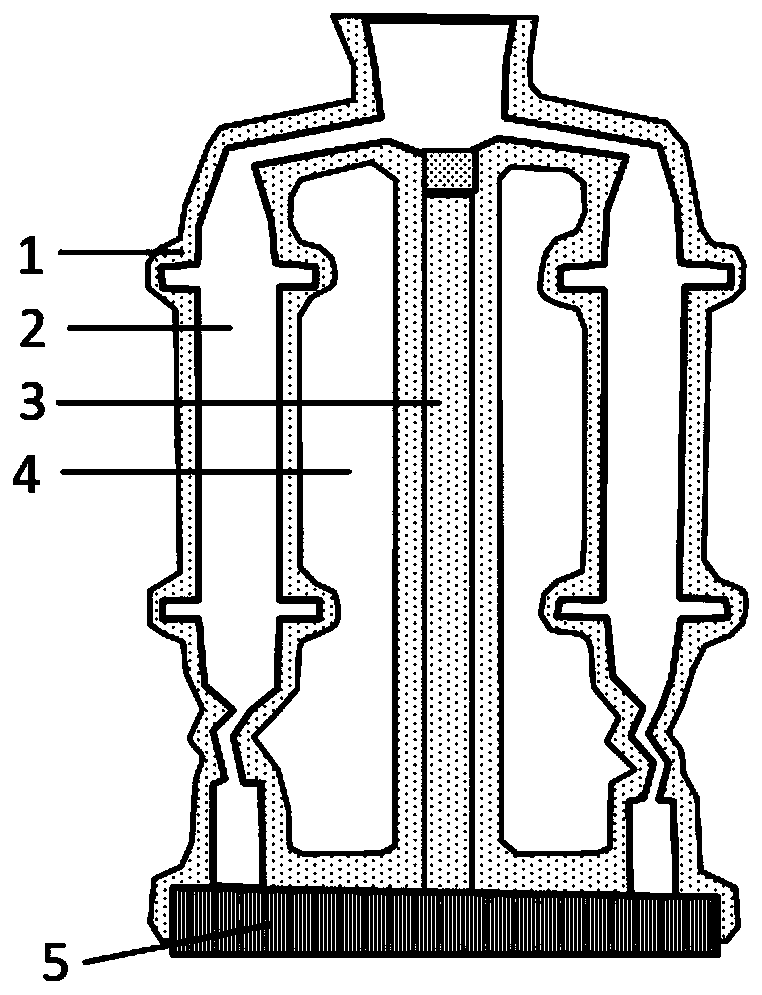

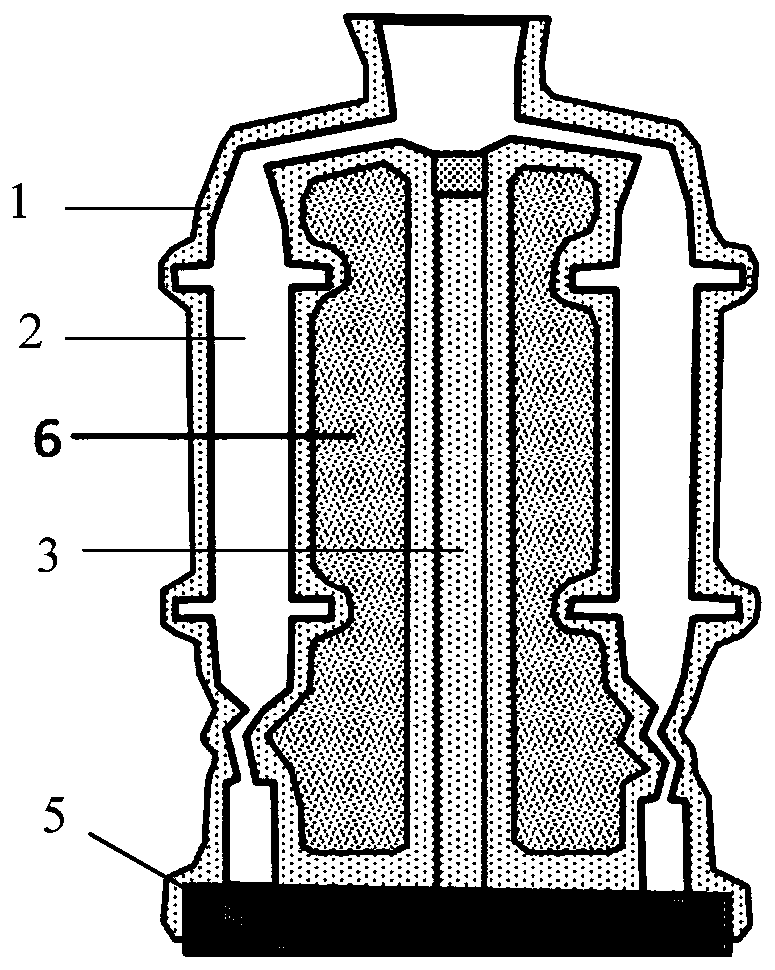

[0028] The invention provides a ceramic formwork, which is used for casting of aero-engine or gas turbine superalloy blades, such as figure 2 As shown, when pouring, it is placed on the top of the water-cooled copper plate 5. The ceramic formwork 1 includes a plurality of blade cavities 2 for casting blades, which are arranged on the outer periphery of the center column 3 to form a ring-shaped structure. The hollow area 4 of the ceramic formwork 1 of the structure is filled with heat insulating material to form a heat insulating plug 6, so as to reduce the heat loss from the hot area to the cold a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap