Technique for environmentally friendly treating industrial residue and waste tar from production of alkynol products

A technology for environmental protection treatment and alkynol, which is applied in tar processing by distillation, chemical instruments and methods, preparation of organic compounds, etc., can solve problems such as environmental pollution and economic loss, and achieve no residue discharge, reduce pollution, and improve recovery. The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

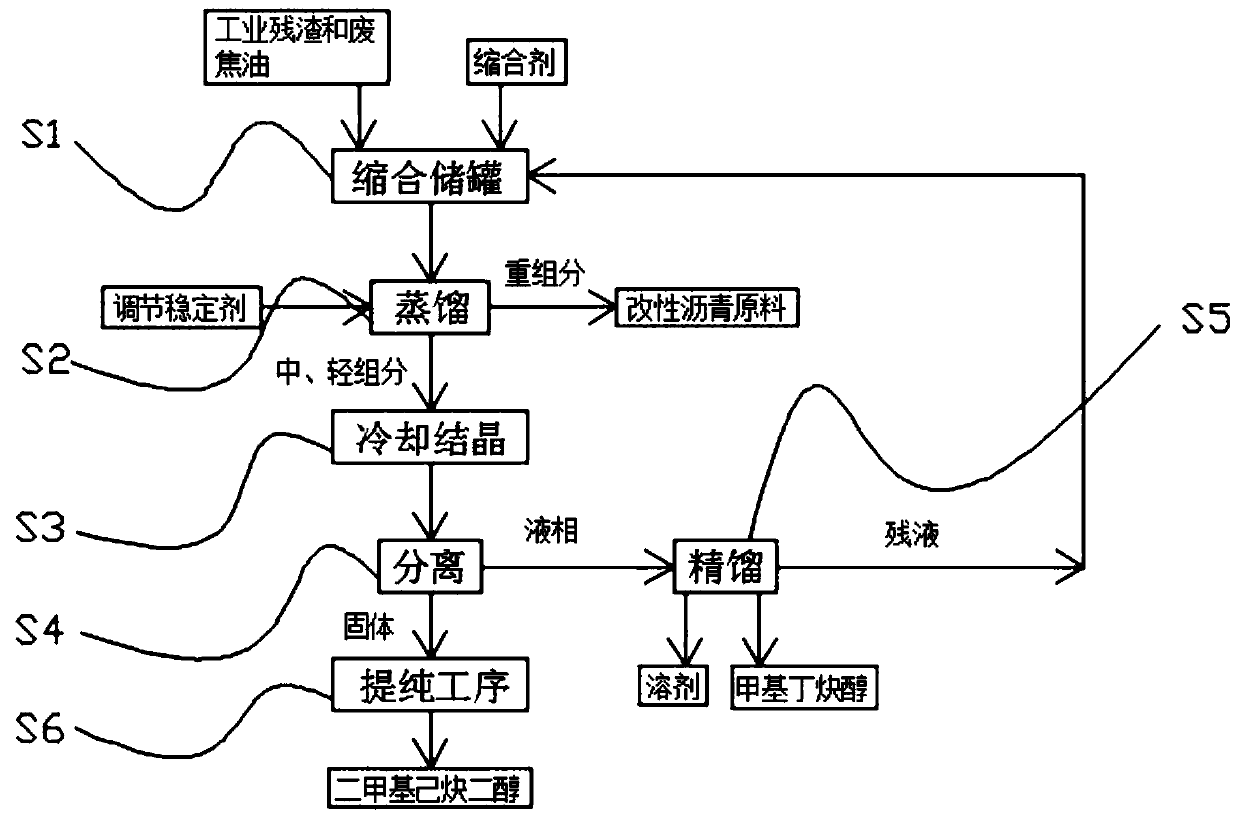

[0022] Such as figure 1 Shown, a kind of technology that environmental protection treatment produces industrial residue and waste tar that acetylenic alcohols products produce comprises the following steps:

[0023] S1, get the industrial residue and waste tar of producing methyl butynol and dimethylhexynediol products in the condensation storage tank, add condensing agent, the addition of condensing agent is 0.01% of industrial residue and waste tar gross weight, Mix evenly and let stand at constant temperature for more than 30 days;

[0024] S2, adding a regulating stabilizer, the amount of regulating stabilizer is 0.01% of the total weight of industrial residues and waste tar, the control distillation temperature is 0 ° C ~ 200 ° C, the distillation pressure is 0 MPa ~ -0.85 MPa, carry out distillation, collect different temperatures The fraction at the point is obtained to obtain the crude product of liquid acetylenic alcohols and the crude product of solid acetylenic alc...

Embodiment 2

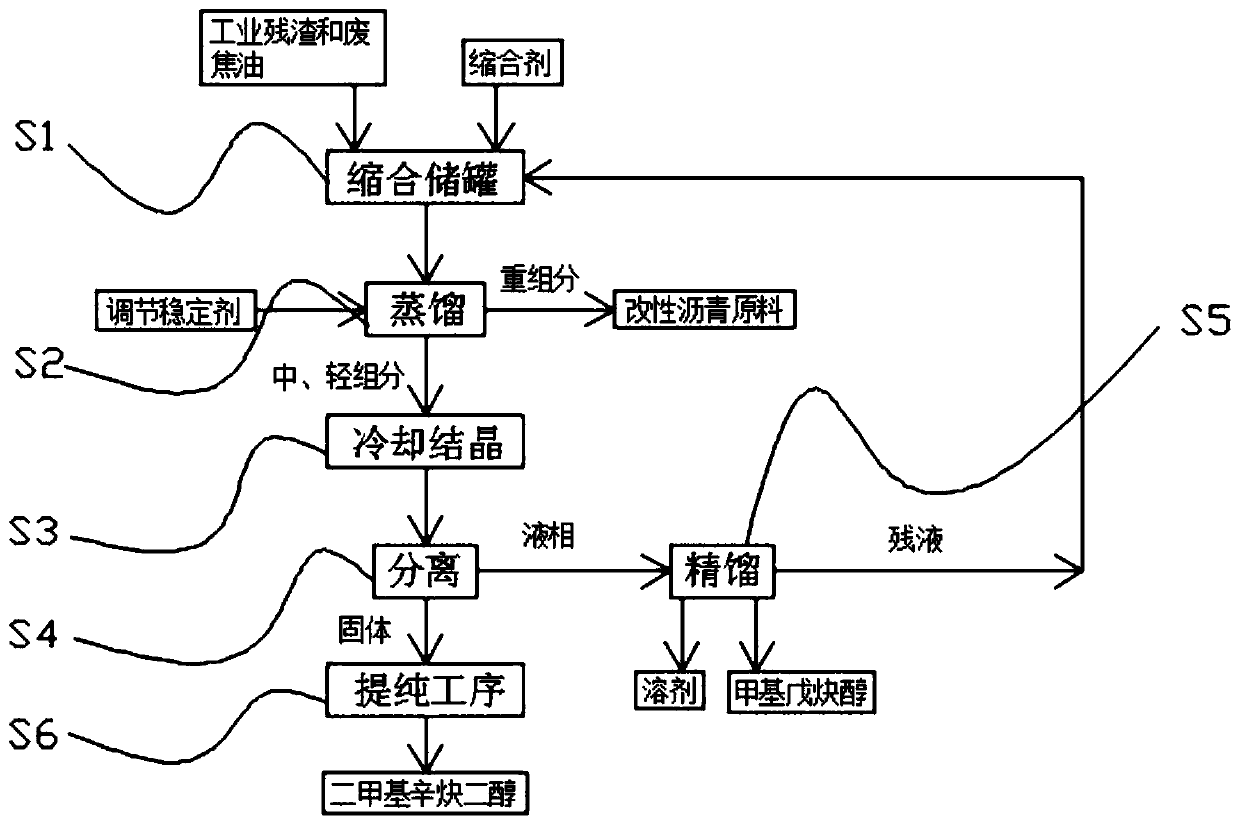

[0031] Such as figure 2 Shown, a kind of technology that environmental protection treatment produces industrial residue and waste tar that acetylenic alcohols products produce comprises the following steps:

[0032] S1, get the industrial residue and waste tar of producing methylpentynol product in the condensation storage tank, add condensing agent, the addition of condensing agent is 0.01% of the total weight of industrial residue and waste tar, mix well, leave standstill at constant temperature for 30 more than days;

[0033] S2, adding a regulating stabilizer, the amount of regulating stabilizer is 0.01% of the total weight of industrial residues and waste tar, the control distillation temperature is 0 ° C ~ 200 ° C, the distillation pressure is 0 MPa ~ -0.85 MPa, carry out distillation, collect different temperatures The fraction at the point is obtained to obtain the crude product of liquid acetylenic alcohols and the crude product of solid acetylenic alcohols and the ...

Embodiment 3

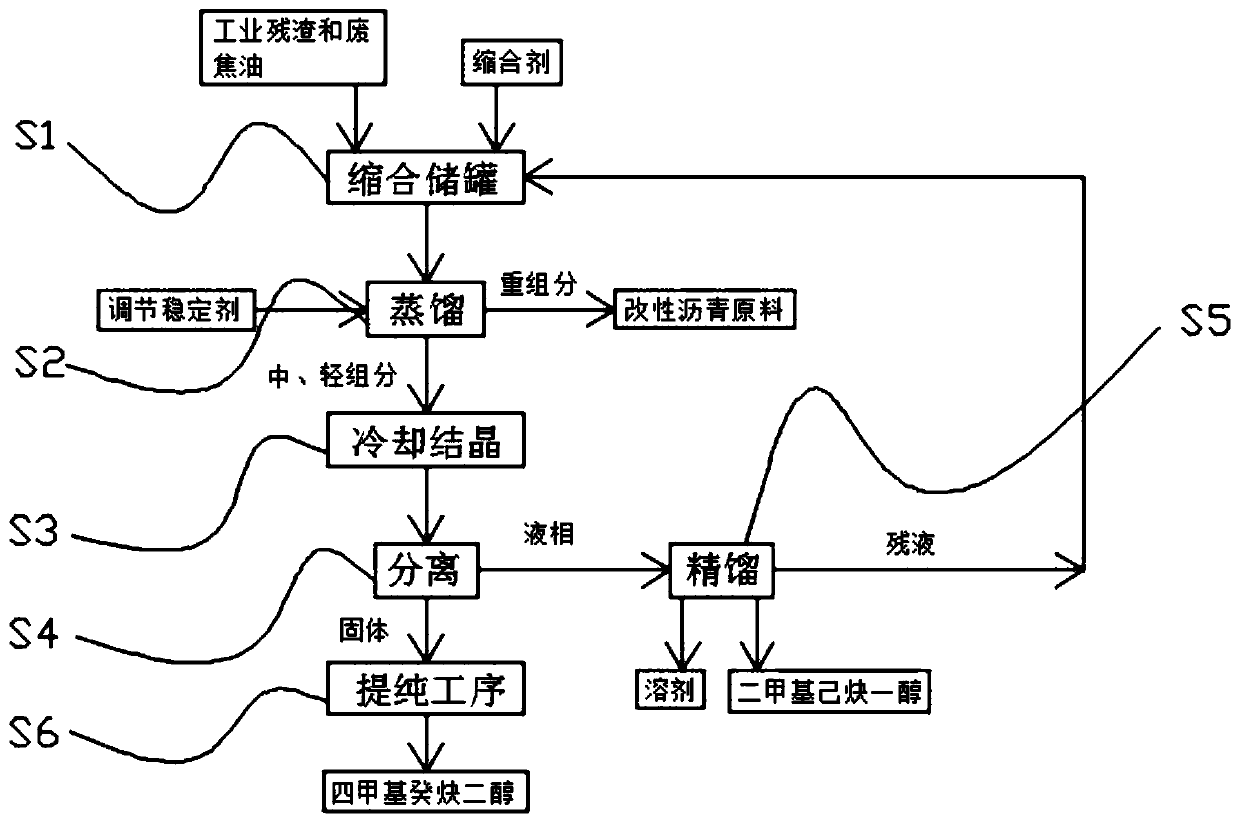

[0040] Such as image 3 Shown, a kind of technology that environmental protection treatment produces industrial residue and waste tar that acetylenic alcohols products produce comprises the following steps:

[0041] S1, get the industrial residue and waste tar from the production of tetramethyldecynediol products in the condensation storage tank, add a condensing agent, the addition of the condensation agent is 0.01% of the total weight of the industrial residue and waste tar, mix evenly, and keep the temperature constant more than 30 days;

[0042] S2, adding a regulating stabilizer, the amount of regulating stabilizer is 0.01% of the total weight of industrial residues and waste tar, the control distillation temperature is 0 ° C ~ 200 ° C, the distillation pressure is 0 MPa ~ -0.85 MPa, carry out distillation, collect different temperatures The fraction at the point is obtained to obtain the crude product of liquid acetylenic alcohols and the crude product of solid acetylen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com