Method and product for preparing carbon dots by using bromoacetonitrile and imidazole compounds

A technology of compounds and imidazoles is applied in the field of preparation of nano-luminescent materials to achieve the effects of controllable conditions, short reaction time, good fluorescence performance and water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Utilize bromoacetonitrile and 1-methylimidazole to prepare the method for carbon point, comprise the following steps:

[0029] (1) Measure 2mL of bromoacetonitrile and 6mL of 1-methylimidazole respectively, pour them into a 50mL beaker, and stir rapidly to make the solutions mix evenly, and leave to react to obtain a reaction solution, which contains carbon dots;

[0030] (2) After naturally cooling the reaction solution obtained in step (1), centrifuge at a speed of 8000 rpm for 10 min in a high-speed centrifuge to obtain a supernatant; The filtrate was dialyzed with a dialysis bag with a molecular weight cut-off of 500 Da for 48 hours, and then freeze-dried to obtain carbon dot powder; finally, a part of the carbon dot powder was dispersed with ultrapure water and ethanol to obtain a carbon dot dispersion, which was stored at 4 °C.

Embodiment 2

[0032] Utilize bromoacetonitrile and 1-methylimidazole to prepare the method for carbon point, comprise the following steps:

[0033] (1) Measure 5mL of bromoacetonitrile and 10mL of 1-methylimidazole respectively, pour them into a 50mL beaker, and stir rapidly to make the solutions mix evenly, and leave to react to obtain a reaction solution, which contains carbon dots;

[0034] (2) After naturally cooling the reaction solution obtained in step (1), centrifuge at a speed of 8000 rpm for 10 min in a high-speed centrifuge to obtain a supernatant; The filtrate was dialyzed with a dialysis bag with a molecular weight cut-off of 500 Da for 48 hours, and then freeze-dried to obtain carbon dot powder; finally, a part of the carbon dot powder was dispersed with ultrapure water and ethanol to obtain a carbon dot dispersion, which was stored at 4 °C.

Embodiment 3

[0036] Utilize bromoacetonitrile and 1-methylimidazole to prepare the method for carbon point, comprise the following steps:

[0037] (1) Measure 5mL of bromoacetonitrile and 5mL of 1-methylimidazole respectively, pour them into a 50mL beaker, stir rapidly to make the solutions mix evenly, and leave to react to obtain the reaction solution, which contains carbon dots;

[0038] (2) After naturally cooling the reaction solution obtained in step (1), centrifuge at a speed of 8000 rpm for 10 min in a high-speed centrifuge to obtain a supernatant; The filtrate was dialyzed with a dialysis bag with a molecular weight cut-off of 500 Da for 48 hours, and then freeze-dried to obtain carbon dot powder; finally, a part of the carbon dot powder was dispersed with ultrapure water and ethanol to obtain a carbon dot dispersion, which was stored at 4 °C.

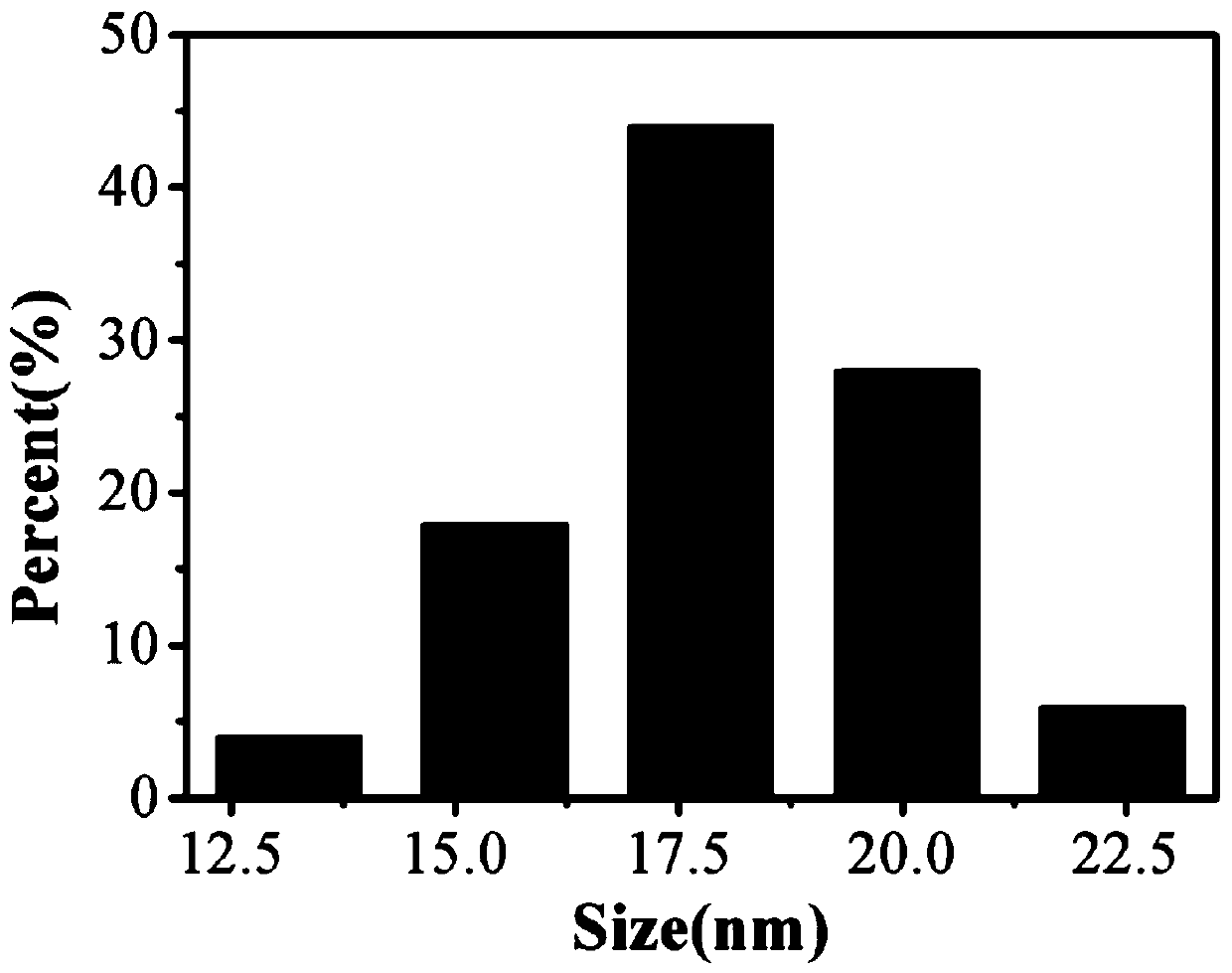

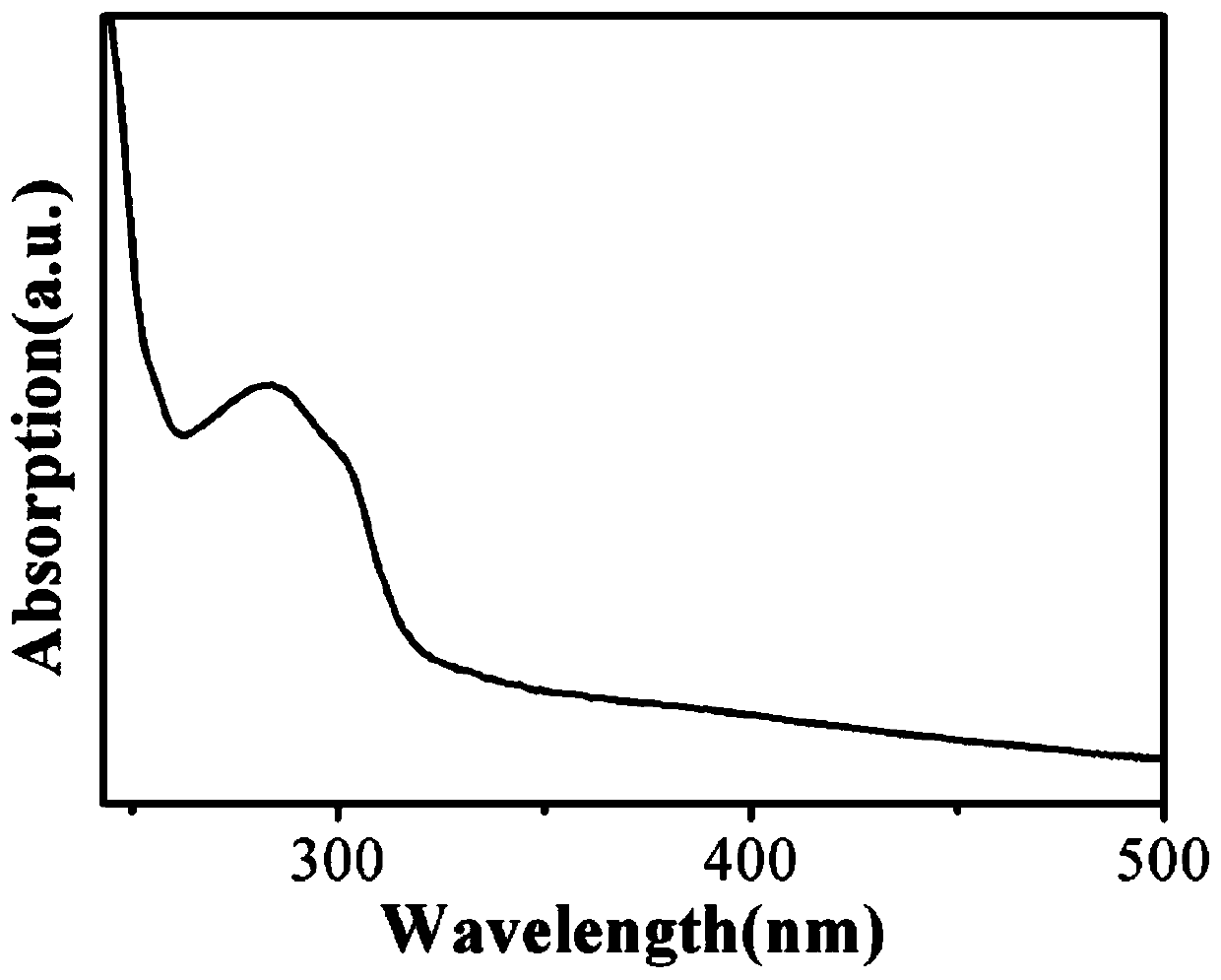

[0039] The obtained carbon dots are characterized:

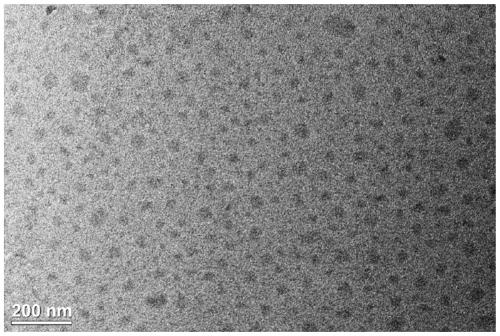

[0040] figure 1 Transmission electron microscope image of carbon dots made for the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com