Optical module

A technology of optical modules and optical fibers, which is applied in the field of optical modules, can solve problems such as the difficulty of achieving high output and difficult alignment when gathering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

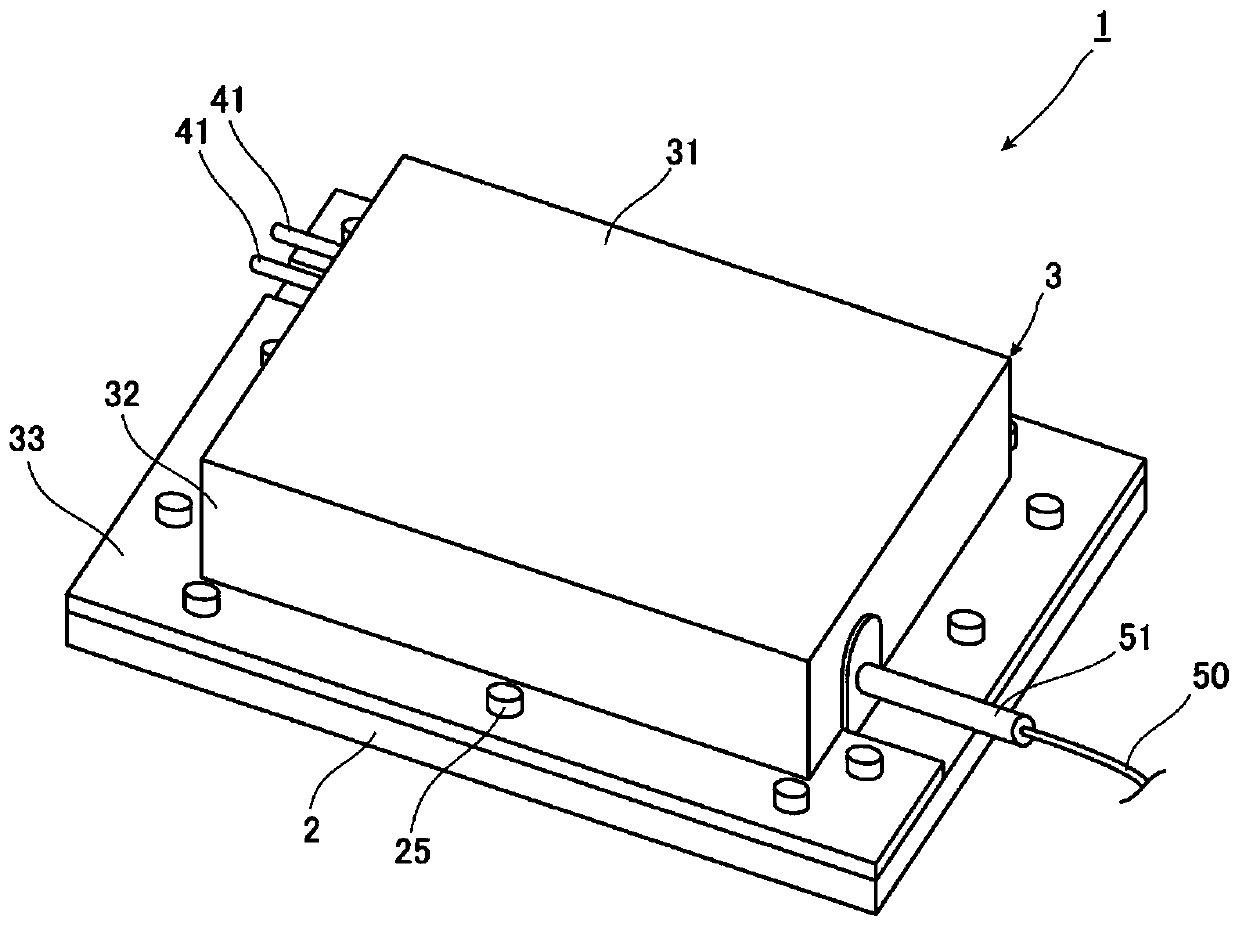

[0045] figure 1 It is a perspective view showing the optical module according to this embodiment. Such as figure 1As shown, the optical module 1 of the present embodiment includes: a housing composed of a base plate 2 and a cover 3; the following optical components fixed in the housing; and a connector 41 for supplying power to some of the optical components. .

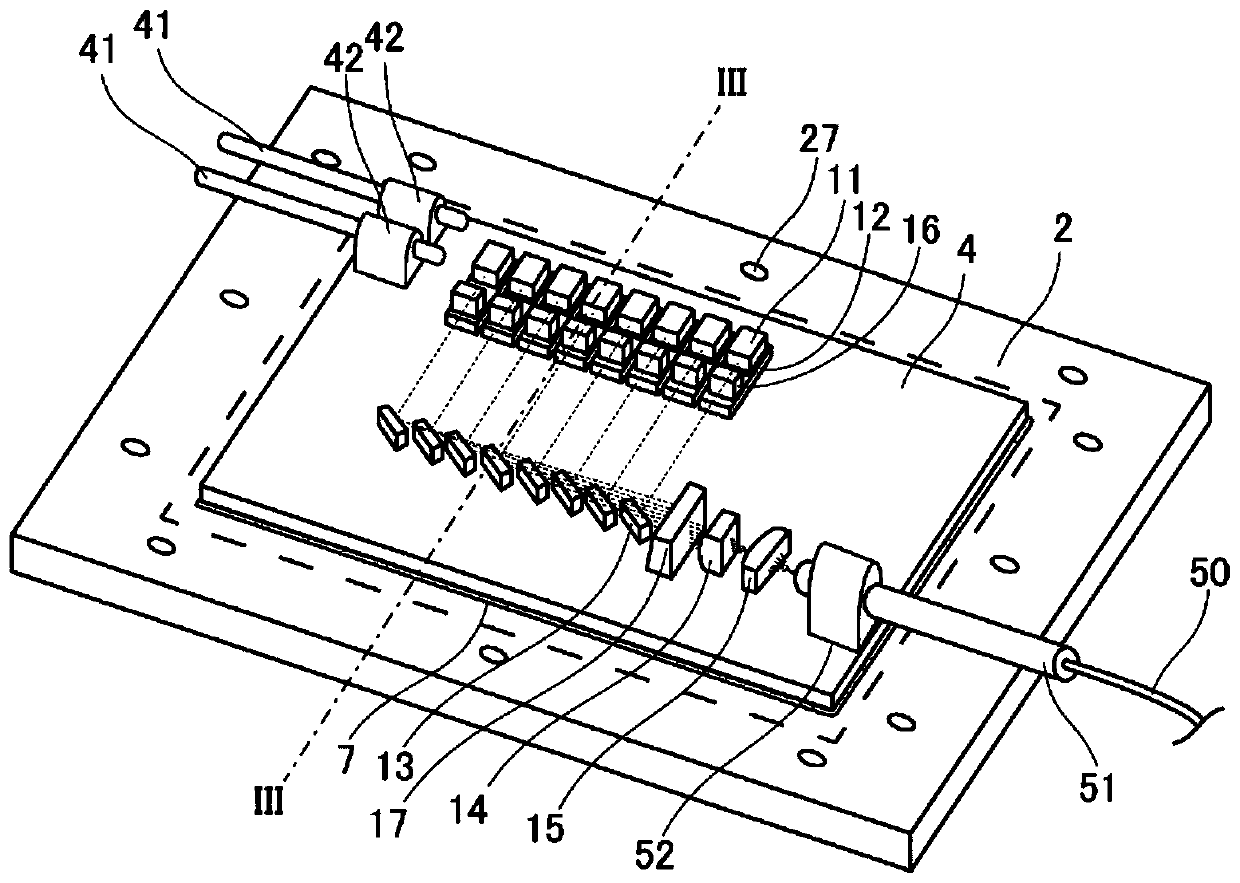

[0046] figure 2 will be figure 1 It is a figure showing that the cover body 3 of the optical module 1 is removed. exist figure 2 In , the optical path of the light emitted from the laser diode 11 is indicated by a dotted line. in addition, image 3 is along figure 2 A cross-sectional view of the optical module 1 along line III-III shown.

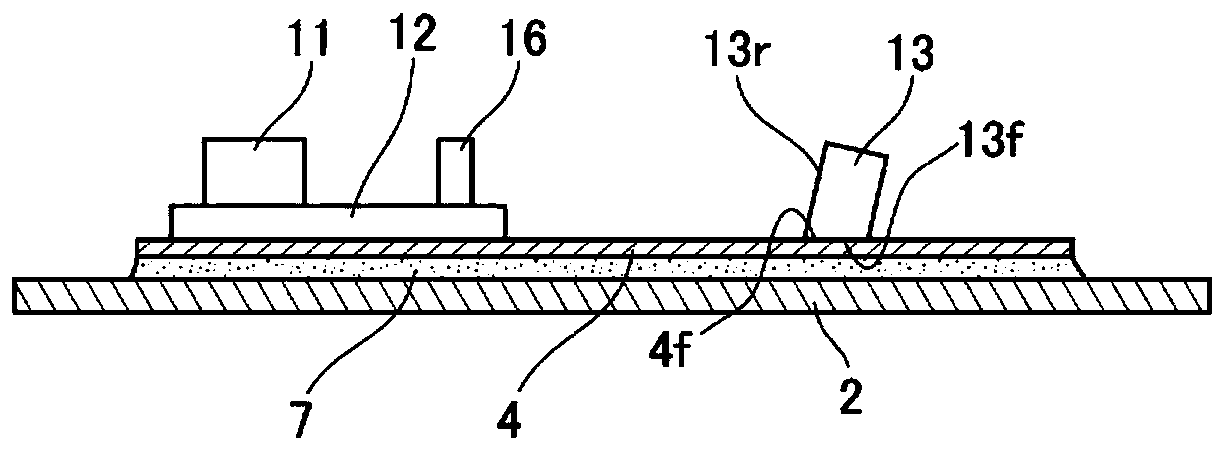

[0047] The base plate 2 is a plate with a planar bottom as the bottom plate of the housing. In this embodiment, as figure 2 and image 3 As shown, it is a flat part. The base plate 2 is made of metal, and examples of the metal constituting the base plate 2 include co...

no. 2 approach

[0078] Next, refer to Figure 7 A second embodiment of the present invention will be described in detail. In addition, about the same or equivalent components as those of the first embodiment, unless otherwise specified, the same reference numerals are attached, and overlapping descriptions are omitted.

[0079] Figure 7 so with Figure 5 The same viewpoint shows the diagram of the optical module according to this embodiment. The optical module 1 a of this embodiment differs from the first embodiment in that it does not include the light refraction member 17 . In addition, since the optical module 1 a does not include the light refraction member 17 , the arrangement of the first condenser lens 14 , the second condenser lens 15 , and the optical fiber 50 is different from that of the first embodiment. In this embodiment, the optical axes of the first condenser lens 14, the second condenser lens 15, and the optical fiber 50 are inclined relative to the surface on which the ...

no. 3 approach

[0081] Next, refer to Figure 8 and Figure 9 A third embodiment of the present invention will be described in detail. In addition, about the same or equivalent components as those of the second embodiment, unless otherwise specified, the same reference numerals are attached, and overlapping descriptions are omitted.

[0082] Figure 8 so with Figure 5 The same viewpoint shows the diagram of the optical module according to this embodiment. Figure 9 will be Figure 8 Shown is an enlarged cross-sectional view of the end of the optical fiber. exist Figure 9 In , the arrow L2 indicates the direction of light propagation. The arrangement of the optical fiber 50 and the shape of the incident end of the optical module 1 b of this embodiment are different from those of the second embodiment. The optical fiber 50 of the present embodiment is arranged such that the optical axis of the optical fiber 50 is parallel to the plane on which the plurality of laser diodes 11 are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com