Full-biodegradable material preparation method, material and product

A fully degradable and fully biological technology, applied in the field of fully biological, materials and products, and fully degradable material preparation methods, can solve the problems of low cost, pollute the environment, and cannot be degraded, and achieve low cost, high processing efficiency and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

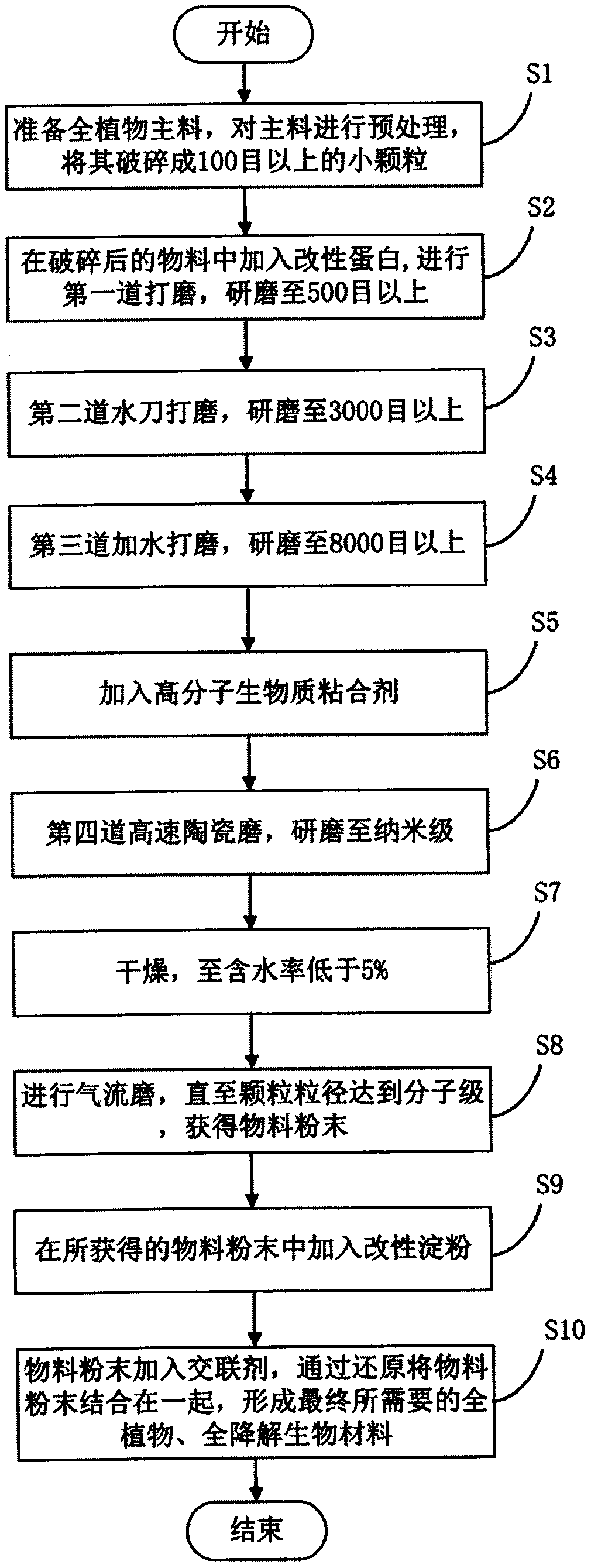

[0043] To this end, the present invention provides a method for preparing a fully biological and fully degradable material, which includes a material processing step and a material reduction step, wherein,

[0044] The material processing steps include:

[0045] S1: Prepare the main material, which is a whole plant main material, pretreat the main material, and crush it into small particles of more than 100 mesh;

[0046] S2: Add modified protein to the crushed material, and perform the first grinding on the material, and grind it to more than 500 mesh;

[0047] S3: Carrying out the second grinding, the second grinding is polished by water jet, and the grinding is more than 3000 mesh;

[0048] S4: Carry out the third grinding with water, and grind to more than 8000 mesh;

[0049] S5: After the third grinding, add a polymer biomass binder;

[0050] S6: Carry out the fourth grinding with water, using high-speed ceramic mill, grinding to nanometer level;

[0051] S7: drying the...

Embodiment 1

[0093] A method for preparing fully biological and fully degradable materials, comprising:

[0094] S1: Prepare the main material, the main material is bagasse, and the bagasse is pretreated to be crushed into small particle materials reaching 100 meshes;

[0095] S2: Add modified protein to the crushed material, and perform the first ordinary mechanical grinding on the material, and grind it to 500 mesh for 1 hour;

[0096] S3: Carry out the second water jet grinding, grinding to 3000 mesh for 3 hours;

[0097] S4: Carry out the third three-roll mill, grind five times, and grind to 8000 mesh;

[0098] S5: After the third grinding, add acrylic modified substance;

[0099] S6: Carry out the fourth grinding with water, using a high-speed ceramic mill, grinding for 1 hour, so that the material particles reach 18,000 mesh, and the particle size reaches 18,000 mesh accounting for more than 70%;

[0100] S7: Dry the material with a high-speed centrifugal spray dryer until the moist...

Embodiment 2

[0105] A method for preparing fully biological and fully degradable materials, comprising:

[0106] S1: Prepare the main material, the main material is corncob, pretreat the corncob, and crush it into small particles reaching 100 mesh;

[0107] S2: Add modified protein to the crushed material, and perform the first ordinary mechanical grinding on the material, and grind it to 500 mesh for 1 hour;

[0108] S3: Carry out the second water jet grinding, grinding to 3000 mesh for 3 hours;

[0109] S4: Carry out the third three-roll mill, grind five times, and grind to 9000 mesh;

[0110] S5: After the third grinding, add acrylic modified substance;

[0111] S6: Carry out the fourth grinding with water, using a high-speed ceramic mill, grinding for 1 hour, so that the material particles reach 18,000 mesh, and the particle size reaches 18,000 mesh accounting for more than 70%;

[0112] S7: Dry the material with a high-speed centrifugal spray dryer until the moisture content is low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com