Method for preparing MCM-22/Beta composite molecular sieve

A technology of MCM-22 and composite molecular sieves, which is applied in molecular sieves and base exchange compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of inappropriate large-scale production, and achieve the effect of easy large-scale production and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

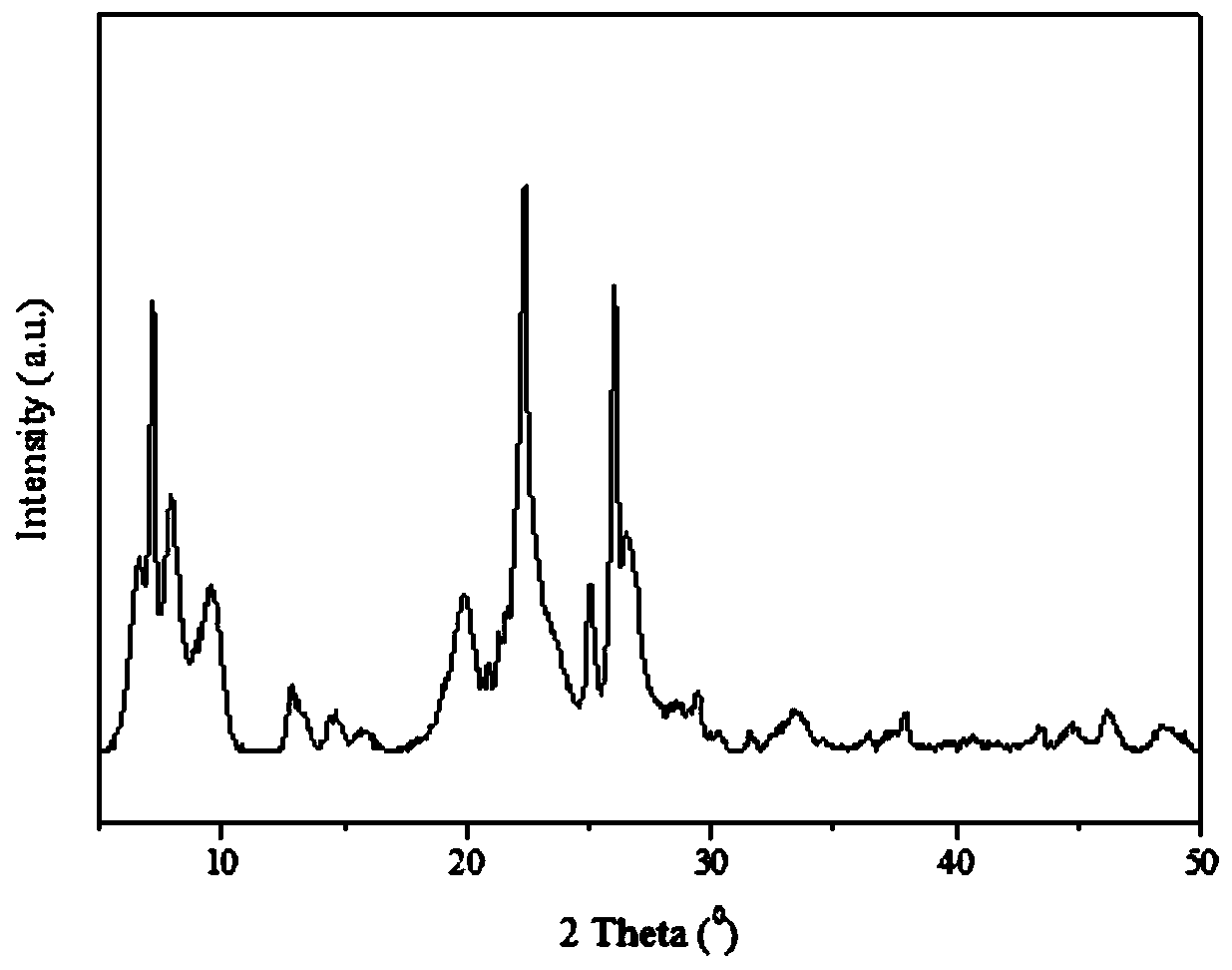

Image

Examples

Embodiment 1

[0016] The raw materials used are as follows:

[0017] (1) Silica sol (30.19wt.% SiO 2 , 0.29 wt.% Na 2 O, 0.23wt.% Al 2 o 3 , 69.29 wt.% H 2 O);

[0018] (2) Sodium metaaluminate (NaAlO 2 , 16.80wt.% Al 2 o 3 , 19.38 wt.% Na 2 O, 63.82 wt.% H 2 O);

[0019] (3) Sodium hydroxide (content ≥ 96%);

[0020] (4) deionized water;

[0021] (5) piperidine;

[0022] (6) Beta molecular sieve.

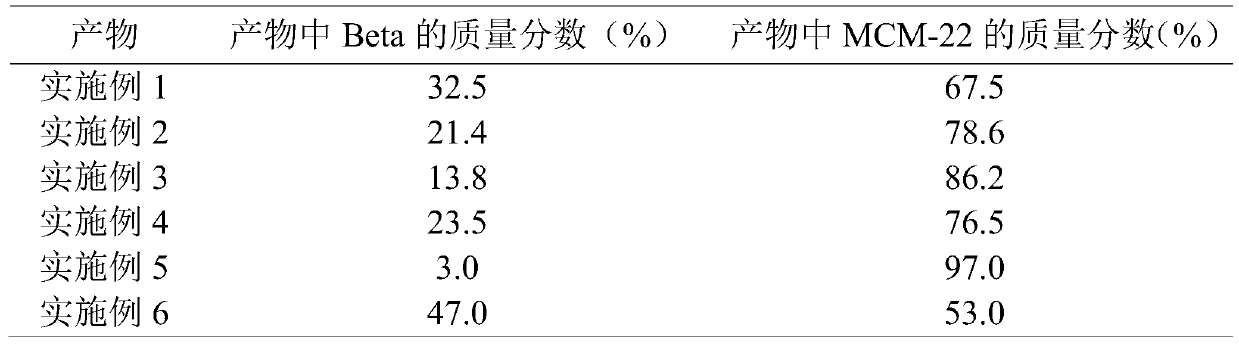

[0023] According to the molar ratio: 0.2Na 2 O: 0.03Al 2 o 3 : 1.0 SiO 2 : 20H 2 O: 0.4R: 30% Beta molecular sieve, stir and mix 198.7g silica sol, 15.5g sodium metaaluminate, 11.5g sodium hydroxide, 212.4g deionized water and 34.1g piperidine in a certain order, then add 18.9g Mix the Beta molecular sieves evenly, add them into the synthesis kettle and seal it, and make it dynamically crystallize at 150° C. for 48 hours. Wash the solid product with deionized water until the washing liquid is neutral, then centrifuge and dry overnight at 120°C to obtain a molecular sieve prod...

Embodiment 2

[0025] The raw materials used are as follows:

[0026] (1) White carbon black (dry basis 86.6%);

[0027] (2) Sodium metaaluminate (NaAlO 2 , 16.80wt.% Al 2 o 3 , 19.38 wt.% Na 2 O, 63.82 wt.% H 2 O);

[0028] (3) Sodium hydroxide (content ≥ 96%);

[0029] (4) deionized water;

[0030] (5) Hexamethyleneimine;

[0031] (6) Beta molecular sieve.

[0032] According to the molar ratio: 0.1Na 2 O: 0.01Al 2 o 3 : 1.0 SiO 2 : 30H 2 O: 0.3R: 20% Beta molecular sieve, mix 69.28g white carbon black, 6.07g sodium metaaluminate, 6.75g sodium hydroxide, 526.8g deionized water and 29.8g hexamethyleneimine in a certain order and mix evenly , and then add 12.2g of Beta molecular sieves and mix evenly, add it into the synthesis kettle and seal it, and make it dynamically crystallize at 160°C for 24h. Wash the solid product with deionized water until the washing liquid is neutral, centrifuge and dry overnight at 120°C to obtain a molecular sieve product, and its X-ray diffraction...

Embodiment 3

[0034] The raw materials used are as follows:

[0035] (1) Silica gel (dry basis 92.7%);

[0036] (2) Sodium metaaluminate (NaAlO 2 , 16.80wt.% Al 2 o 3 , 19.38 wt.% Na 2 O, 63.82 wt.% H 2 O);

[0037] (3) Sodium hydroxide (content ≥ 96%);

[0038] (4) deionized water;

[0039] (5) piperidine;

[0040] (6) Beta molecular sieve.

[0041] According to the molar ratio: 0.5Na 2 O: 0.04Al 2 o 3 : 1.0 SiO 2 : 15H2 O: 0.5R: 15% Beta molecular sieve, stir and mix 64.7g silica gel, 24.3g sodium metaaluminate, 35.3g sodium hydroxide, 249.8g deionized water and 42.6g piperidine in a certain order, and then add 9.15g Beta Molecular sieves were mixed evenly, added to the synthesis kettle and then sealed for dynamic crystallization at 140°C for 56 hours. Wash the solid product with deionized water until the washing liquid is neutral, centrifuge and dry overnight at 120°C to obtain a molecular sieve product, and its X-ray diffraction (XRD) spectrum is consistent with figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com