Filling material and using method thereof

A filling material and modification technology, applied in the field of filling materials, can solve the problems of low cohesion of filling paste, easy segregation of slurry, increased bleeding, etc., achieve low cohesion, reduce use and treatment costs , the effect of large water permeability coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

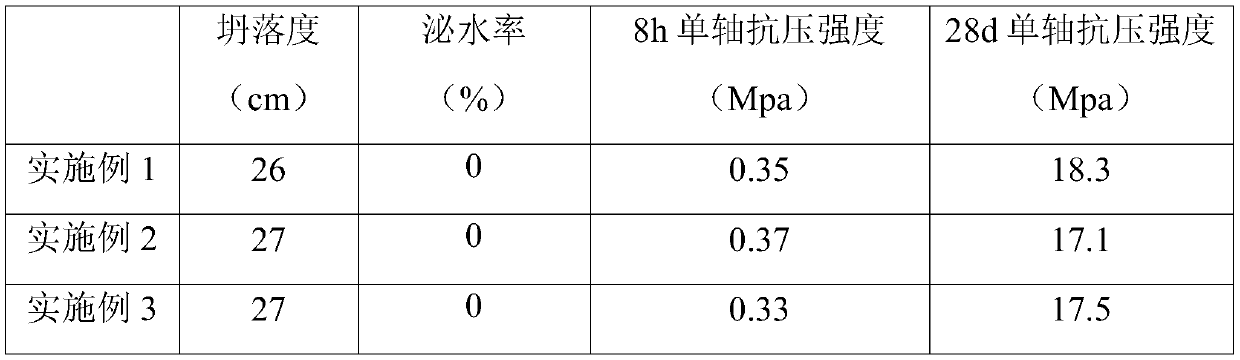

Examples

Embodiment 1

[0031] A filling material, including the following components in mass percentage:

[0032] 8% cement, 30% fly ash, 25% coal gangue, 35% aeolian sand, 2% plant fiber;

[0033] Described cement comprises the component of following mass percentage:

[0034] Modified mineral powder 55%, composite gypsum 25%, Portland cement clinker 12%, composite admixture 8%.

[0035] Wherein, fly ash comprises the component of following mass content: 45% SiO 2 , 20% Al 2 o 3 , 6% FeO, 5% Fe 2 o 3 , 2% CaO and 1% TiO 2 ; The sieve residue of fly ash passing through the 45μm square hole sieve is 20%, the loss on ignition is 7%, the water requirement ratio is 98%, SO 3 The mass content is 1.5%.

[0036]The particle size of coal gangue is ≤25mm, and the coal gangue with particle size ≤5mm accounts for 55% of the total coal gangue mass; In the sub-workshop, the vibrating screen is used for preliminary screening, and the coal gangue with a particle size of ≤25mm is transported to the coal gan...

Embodiment 2

[0046] A filling material, including the following components in mass percentage:

[0047] 9% cement, 28% fly ash, 28% coal gangue, 34% aeolian sand, 1% plant fiber;

[0048] Described cement comprises the component of following mass percentage:

[0049] Modified mineral powder 58%, composite gypsum 22%, Portland cement clinker 11%, composite admixture 9%.

[0050] Wherein, fly ash comprises the component of following mass content: 50% SiO 2 , 25% Al 2 o 3 , 8% FeO, 6% Fe 2 o 3 , 3% CaO and 2% TiO 2 ; The sieve residue of fly ash passing through the 45μm square hole sieve is 15%, the loss on ignition is 5%, the water requirement ratio is 101%, SO 3 The mass content is 2%.

[0051] The particle size of coal gangue is less than or equal to 25mm, and the coal gangue with a particle size of less than or equal to 5mm accounts for 60% of the total coal gangue mass; the crushing process of coal gangue is firstly screened and then crushed, and the hand-selected raw coal gangue...

Embodiment 3

[0061] A filling material, including the following components in mass percentage:

[0062] 10% cement, 25% fly ash, 30% coal gangue, 30% aeolian sand, 5% plant fiber;

[0063] Described cement comprises the component of following mass percentage:

[0064] Modified mineral powder 60%, composite gypsum 20%, Portland cement clinker 10%, composite admixture 10%.

[0065] Wherein, fly ash comprises the component of following mass content: 55% SiO 2 , 30% Al 2 o 3 , 10% FeO, 8% Fe 2 o 3 , 5% CaO and 2% TiO 2 ; The sieve residue of fly ash passing through the 45μm square hole sieve is 12%, the loss on ignition is 8%, the water requirement ratio is 103%, and the SO 3 The mass content is 3%.

[0066] The particle size of coal gangue is ≤25mm, and the coal gangue with a particle size of ≤5mm accounts for 65% of the total coal gangue quality; In the sub-workshop, the vibrating screen is used for preliminary screening, and the coal gangue with a particle size of ≤25mm is transpor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com