Conductive oil gel and preparation method thereof

A conductive oil and gel technology, applied in the field of conductive oil gel and its preparation, can solve the problems of limiting practical application, loss of elasticity and conductivity, etc., to improve biocompatibility and mechanical properties, increase types, and improve mechanics The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

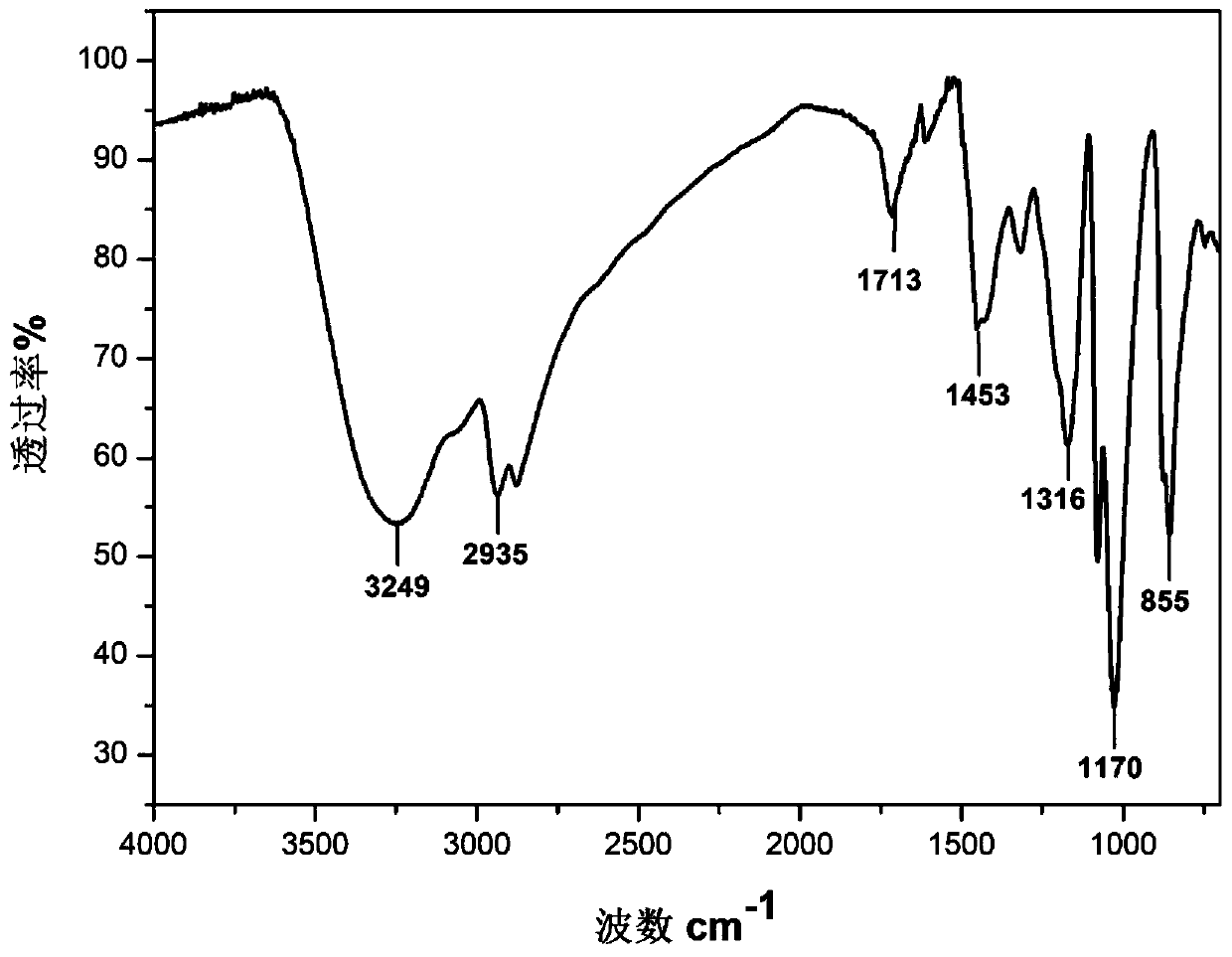

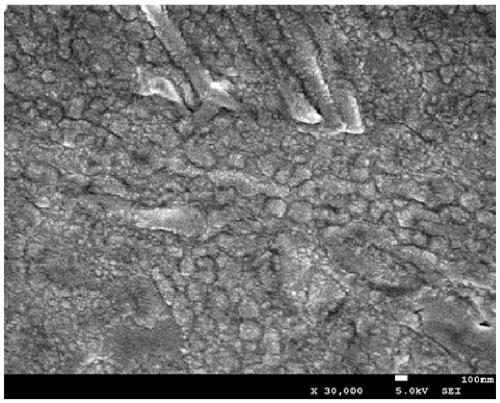

[0033] In this embodiment, the preparation method of conductive oil gel is provided, and the steps are as follows:

[0034] (1) Configure the first solution

[0035] Weigh 342 mg of ammonium persulfate (1.5 mmol), add 0.5 ml of deionized water, and stir.

[0036] (2) Configure the second solution

[0037] 9.5 mg (0.06 mmol) of 3-aminophenylboronic acid monohydrate was added to 407 μL of concentrated hydrochloric acid. Add 1000 μL of ultrapure water, 91 μL of aniline monomer, and 3 mL of 10 wt % polyvinyl alcohol solution.

[0038] (3) The prepared first solution and the second solution were mixed at -4°C and left for 12 hours.

Embodiment 2

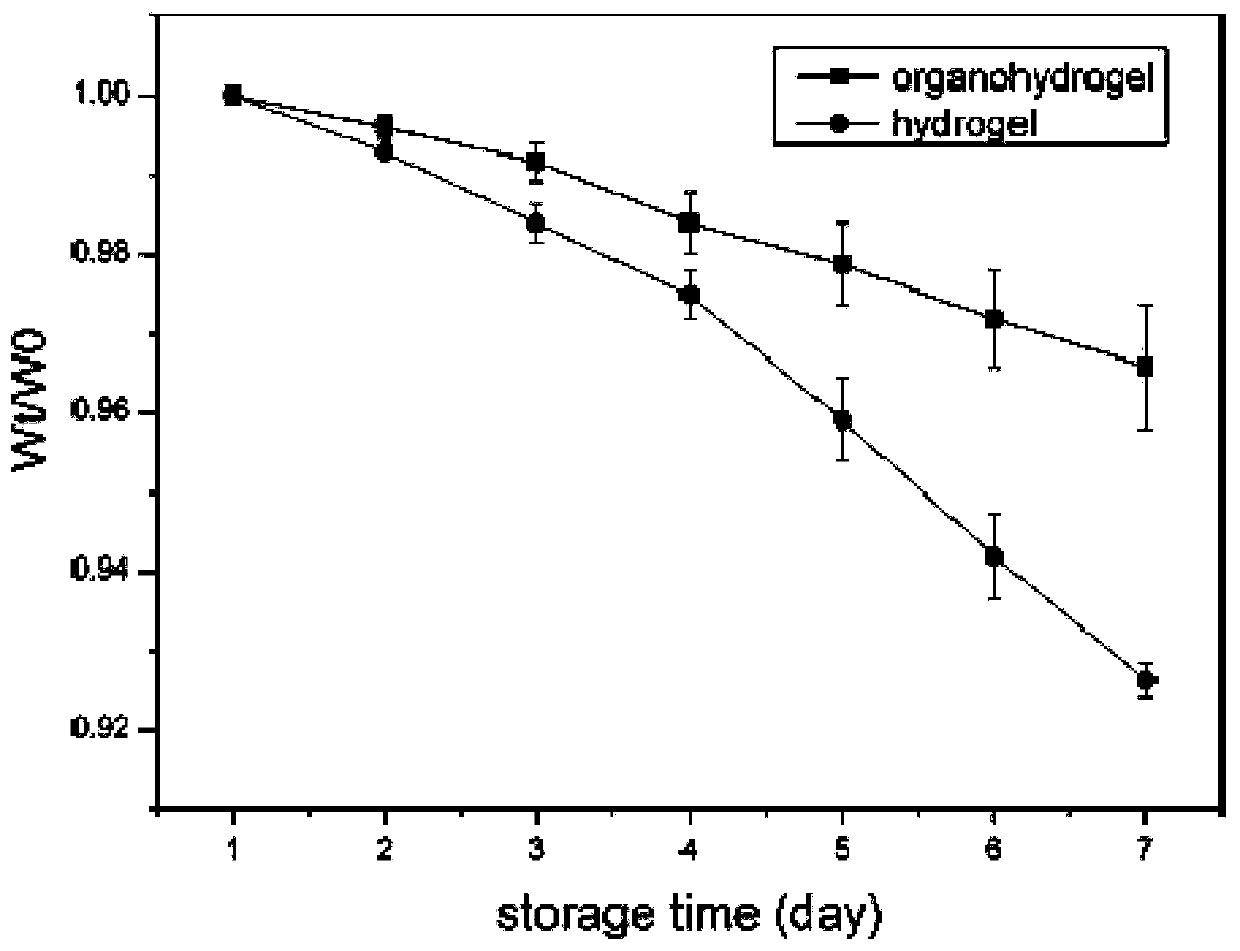

[0040] In this embodiment, the preparation method of conductive oil gel is provided, and the steps are as follows:

[0041] (1) Configure the first solution

[0042] Weigh 342 mg of ammonium persulfate (1.5 mmol), add 0.5 ml of deionized water, and stir.

[0043] (2) Configure the second solution

[0044] 9.5 mg (0.06 mmol) of 3-aminophenylboronic acid monohydrate was added to 407 μL of concentrated hydrochloric acid. Add 600 μL of ethylene glycol, 400 μL of ultrapure water, 91 μL of aniline monomer, and 3 mL of 10 wt % polyvinyl alcohol solution.

[0045] (3) The prepared first solution and the second solution were mixed at -4°C and left for 12 hours.

Embodiment 3

[0047] In this embodiment, the preparation method of conductive oil gel is provided, and the steps are as follows:

[0048] (1) Configure the first solution

[0049] Weigh 342 mg of ammonium persulfate (1.5 mmol), add 0.5 ml of deionized water, and stir.

[0050] (2) Configure the second solution

[0051] 9.5 mg (0.06 mmol) of 3-aminophenylboronic acid monohydrate was added to 407 μL of concentrated hydrochloric acid. Add 750 μL ethylene glycol, 250 μL ultrapure water, 91 μL aniline monomer, and 3 mL 10 wt % polyvinyl alcohol solution.

[0052] (3) The prepared first solution and the second solution were mixed at -4°C and left for 12 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com