Preparation method of poly(n-isopropylacrylamide) inverse opal hydrogel

A technology of isopropyl acrylamide and inverse opal, which is applied in the fields of polymer materials and nanomaterials, can solve the problems of poor mechanical properties, single function and slow response of inverse opal hydrogels, and achieve excellent mechanical properties and simple equipment. , easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

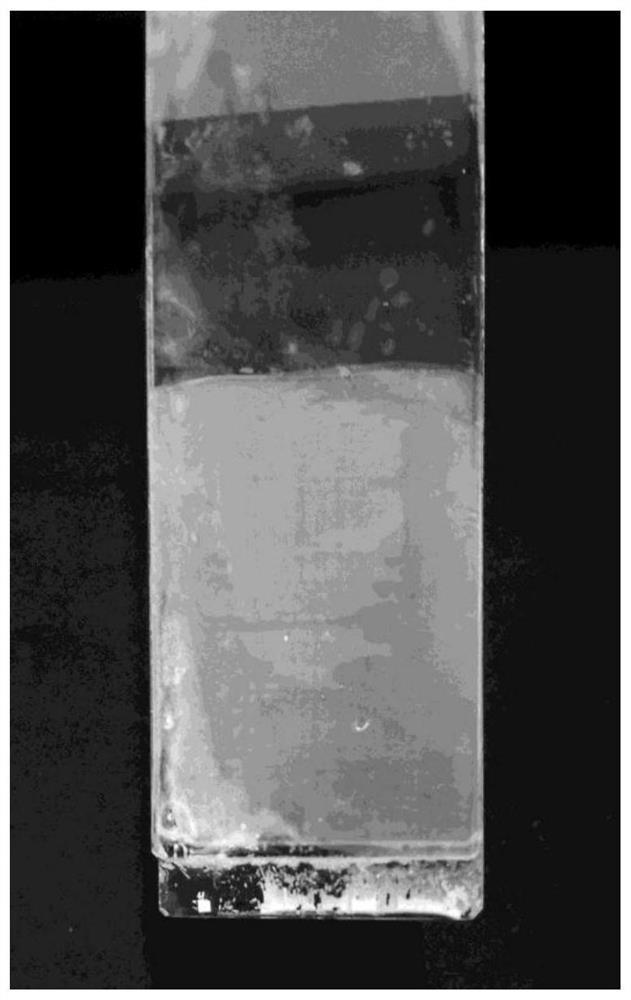

Image

Examples

Embodiment 1

[0035] A preparation method of physically cross-linked poly(N-isopropylacrylamide) inverse opal hydrogel, comprising the following specific steps:

[0036] 1) Synthesis of polystyrene microspheres:

[0037] Add 12g of styrene monomer to 150mL of deionized water and stir to disperse for 1 hour at a stirring speed of 350 rpm. After the dispersion is complete, add 0.2g of acrylic acid and 0.3g of potassium persulfate. After the addition, slowly raise the temperature to 75°C. Continue to react for 8 hours. After the reaction is over, put the obtained emulsion into a centrifuge and centrifuge 3 times for 30 minutes each time. After each centrifugation, remove the supernatant and then add deionized water. Finally, the centrifuged polyphenylene The ethylene microspheres were dried in an oven to obtain polystyrene microspheres with a particle diameter of 275 nm.

[0038] 2) Preparation of polystyrene photonic crystal:

[0039] The polystyrene microspheres obtained above were formula...

Embodiment 2

[0048] A preparation method of physically crosslinked poly(N-isopropylacrylamide) inverse opal hydrogel is characterized in that it comprises the following specific steps:

[0049] 1) Synthesis of polystyrene microspheres: 10 g of styrene monomer was taken, and other conditions were as in step 1) of Example 1 to obtain polystyrene microspheres with a particle diameter of 230 nm.

[0050] 2) Preparation of polystyrene photonic crystals: as in step 2) of Example 1, polystyrene photonic crystals with a green structural color were obtained.

[0051] 3) Preparation of carbon dots (C-dots): as in step 3) of Example 1.

[0052] 4) Preparation of physically cross-linked poly(N-isopropylacrylamide) (PNIPAm) hydrogel precursor solution: the mass fraction of hectorite was 2%, and other conditions were as in step 4) of Example 1.

[0053] 5) Preparation of physically cross-linked poly(N-isopropylacrylamide) (PNIPAm) inverse opal hydrogel: as in step 5 of Example 1), under constant condit...

Embodiment 3

[0055] A preparation method of physically crosslinked poly(N-isopropylacrylamide) inverse opal hydrogel is characterized in that it comprises the following specific steps:

[0056] 1) Synthesis of polystyrene microspheres: 8 g of styrene monomer was taken, and other conditions were as in step 1) of Example 1 to obtain polystyrene microspheres with a particle diameter of 210 nm.

[0057] 2) Preparation of polystyrene photonic crystals: as in step 2) of Example 1, polystyrene photonic crystals with blue structural color were obtained.

[0058] 3) Preparation of carbon dots (C-dots): as in step 3) of Example 1.

[0059] 4) Preparation of physically cross-linked poly(N-isopropylacrylamide) (PNIPAm) hydrogel precursor solution: the mass fraction of hectorite is 1%, and other conditions are as in step 4 of Example 1).

[0060] 5) Preparation of physically cross-linked poly(N-isopropylacrylamide) (PNIPAm) inverse opal hydrogel: as in step 5 of Example 1), under constant conditions, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com