Self-repairing anticorrosive polyurethane coating and preparation method thereof

An anti-corrosion coating and polyurethane technology, applied in the direction of polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., can solve problems such as the combination of self-healing mechanisms, and achieve the effects of good anti-corrosion effect, excellent self-healing performance and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific technical solutions of the present invention are described in conjunction with the examples.

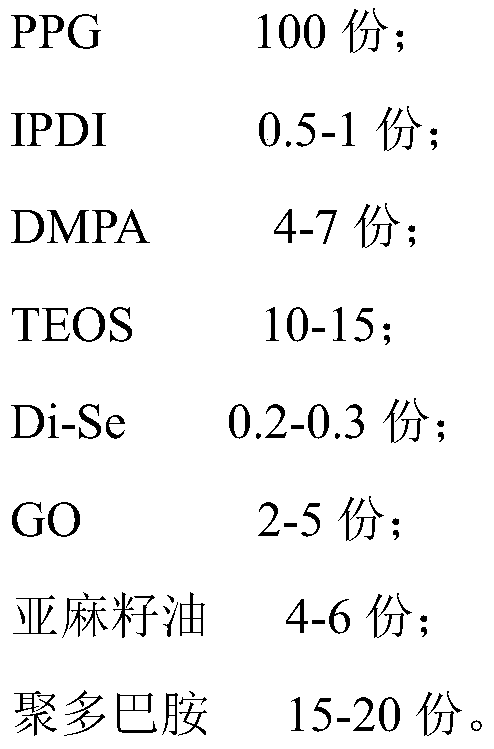

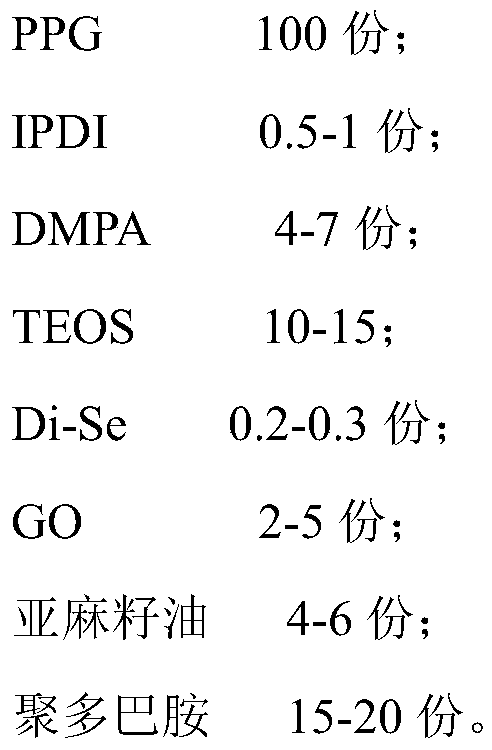

[0017] Polypropylene glycol (PPG), isophorone diisocyanate (IPDI), and dimethylolpropionic acid (DMPA) were vacuum-dried at 110±2°C for 12 hours. Under the protection of dry nitrogen, 100 parts of PPG, 0.5 parts of IPDI and 5 parts of DMPA were used to prepare prepolymers in a three-necked flask under the action of a catalyst at 55 °C; the first-level coating of waterborne polyurethane was synthesized by chain extension and emulsification processes. The tested emulsion is a milky white stable emulsion with excellent thermal performance parameters. Using 10 parts of tetraethoxy silicon orthosilicate (TEOS) as the wall material, 4 parts of linseed oil as the core material, and 18 parts of polydopamine as the nano-valve, the nano-silicon microspheres were synthesized.

[0018] Through scanning electron microscope analysis, the surface of the microspheres is smooth a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com