Span-type oil testing and re-fracturing tool system

A refracting and tool technology, applied in sealing/packing, wellbore/well components, production fluid, etc., can solve problems such as difficult construction of horizontal wells, poor tool compatibility, interference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

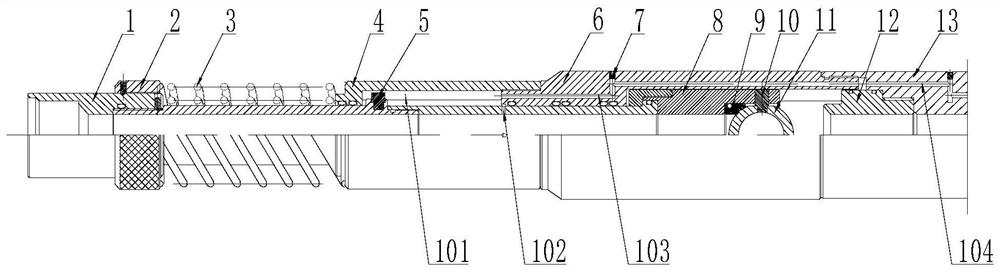

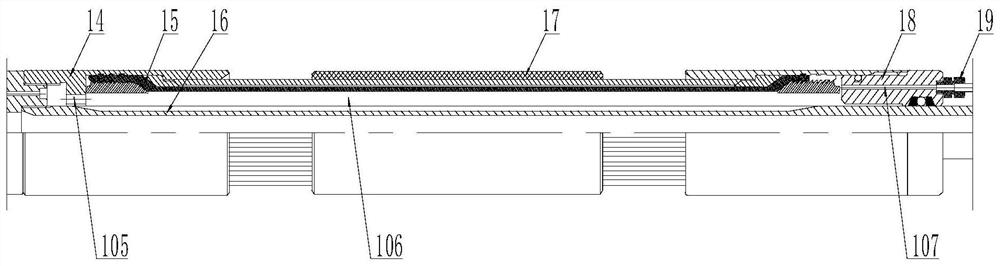

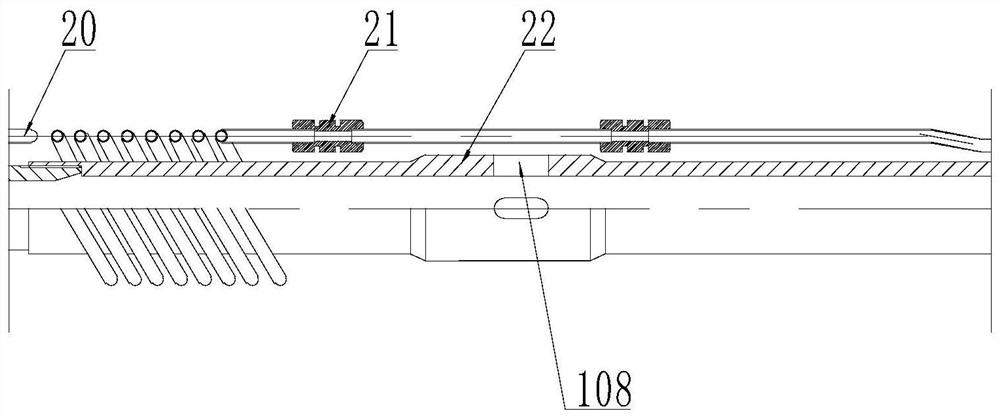

[0040] Such as Figure 1-4 As shown, the spanning oil testing and refracturing tool system is mainly composed of a lift-and-release ball valve setting tool, an upper packer, a spanning center pipe tool, and a lower packer. It is a multi-purpose tool combination.

[0041] The lifting and releasing ball valve type setting tool is mainly composed of: upper joint 1, adjusting screw sleeve 2, spring 3, movable sleeve 4, torque pin 5, switch sleeve 6, blind plug 7, ball valve support 8, ball valve sealing seat 9, ball valve Rotating handle 10, ball valve 11, middle joint 12, lower joint 13 forms. Wherein, the adjusting screw sleeve 2, the spring 3, the movable sleeve 4 and the torque pin 5 form a switch action assembly. Ball valve support 8, ball valve sealing seat 9, ball valve handle 10, ball valve 11 and intermediate joint 12 form a ball valve assembly. The switch sleeve 6 and the lower joint 13 form a bypass pressure transmission channel assembly.

[0042] The upper packer i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com