Resistance-changing capacitance-changing composite two-dimensional strain sensor and preparation method thereof

A two-dimensional strain and sensor technology, which can be used in the measurement of fluid pressure by changing capacitance, fluid pressure measurement by changing ohmic resistance, and measurement of property force by applying piezoelectric resistance materials. It can solve the problem of high process requirements, signal noise It has the advantages of simple manufacturing process, high sensitivity characteristics and good development prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

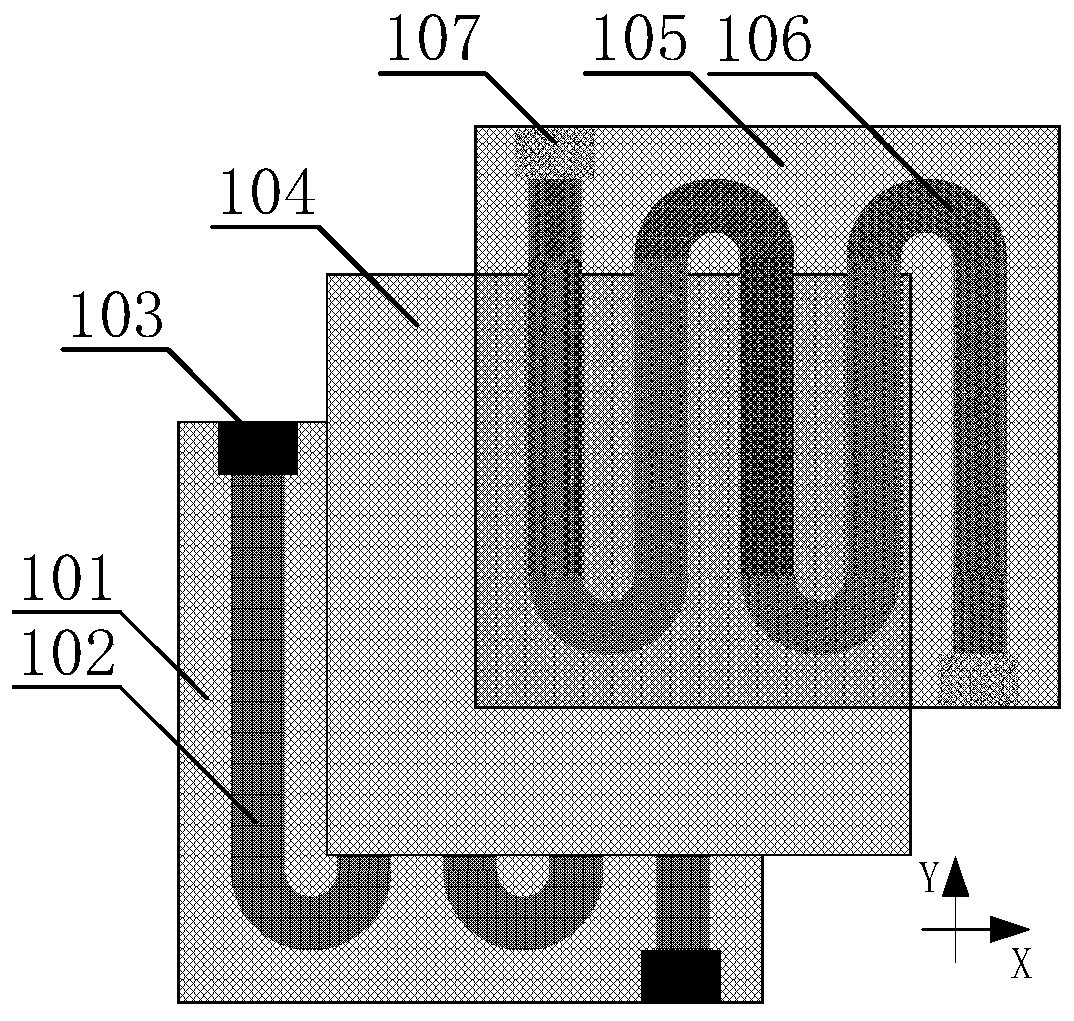

[0030] Such as Figure 5 The RCV composite two-dimensional strain sensor implemented in this embodiment adopts the structural design of the serpentine conductive upper plate 501, the insulating dielectric layer 502, the serpentine conductive lower plate 503, and the encapsulation layer 504 of the parallel plate capacitor.

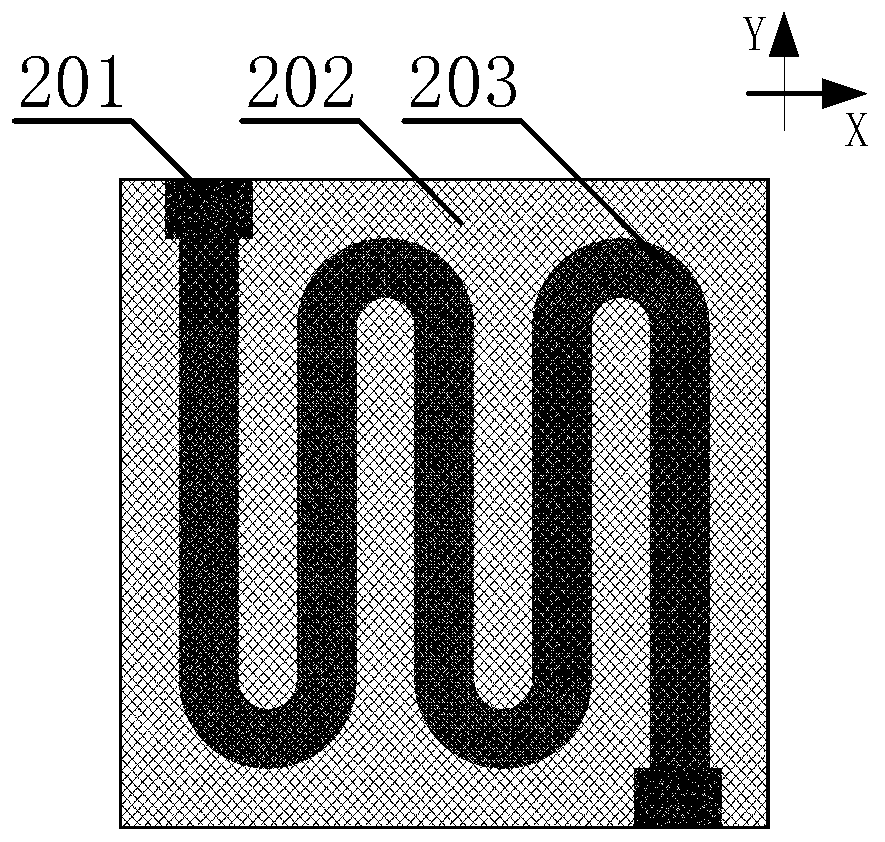

[0031] according to the structure figure 1 The serpentine conductive upper plate includes a flexible substrate 104, silver nanowire conductive network 106, and metal electrodes 107; the insulating dielectric layer 104 serves as the flexible base of the serpentine conductive upper plate; the serpentine conductive lower plate includes a flexible substrate 101, Silver nanowire conductive network 102, metal electrode 103; packaging layer 105 uses polydimethylsiloxane to package the two-dimensional strain sensor. The preparation process of the two-dimensional strain sensor with silver nanowire as conductive material, copper as metal electrode, polydimethylsilox...

Embodiment 2

[0048] The conductive material of the snake-shaped conductive upper and lower plates is not limited to the use of metal materials with micro-nano structures, but also metal carbon materials with micro-nano structures. This example will introduce the resistance switch based on multi-walled carbon nanotube conductive materials The invention discloses a method for preparing a two-dimensional strain sensor of a capacitive compound.

[0049] (1) The composition ratio and preparation method of the flexible substrate: the same as the preparation method in Step 1 of Example 1.

[0050] (2) Preparation method of serpentine pattern mask: the same as the preparation method of step 2 of embodiment 1.

[0051] (3) Preparation method of serpentine conductive bottom plate:

[0052] The snake-shaped conductive lower plate uses multi-walled carbon nanotubes as the conductive material. , purity: 98%, model: M3, Beijing Boyu Gaoke New Material Technology Co., Ltd.) 50mg, deionized water 10mL, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com