Photovoltaic cell surface passivation system and passivation method

A photovoltaic cell, silicon nitride film technology, applied in photovoltaic power generation, circuits, electrical components and other directions, can solve the problems of high risk of unfinished products, low production efficiency, high production cost, reduce multiple processing, improve production efficiency, The effect of reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

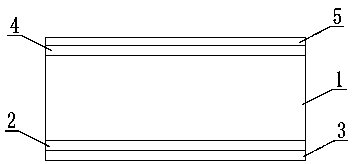

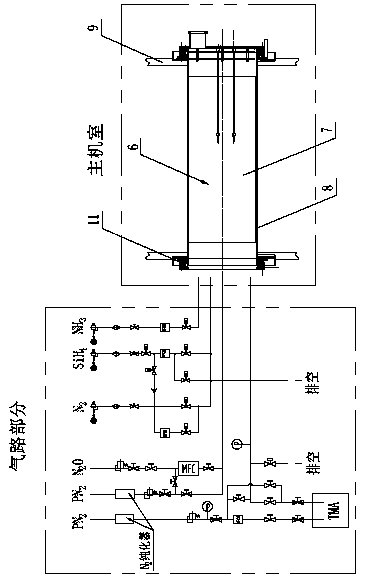

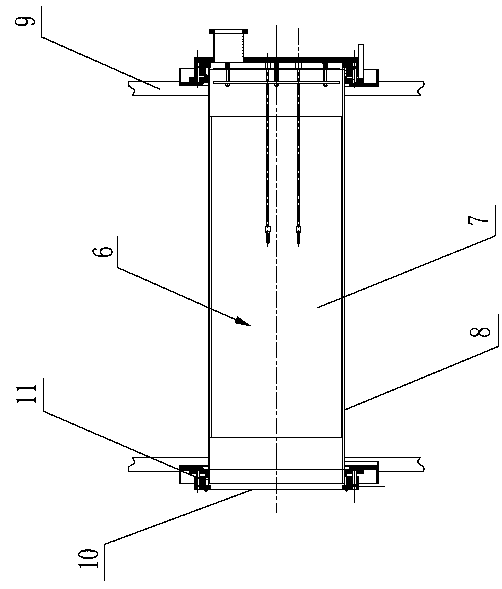

[0037] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0038] In this patent, the "multifunctional PECVD" refers to PECVD equipment that can deposit tunneling oxide layers, amorphous silicon layers, silicon nitride layers, etc. in the same chamber, and is used in this patent for the Silicon wafer 1 backside deposition for TOPCon cells. The "PEALD" refers to a PEALD device that can deposit all or any of the films of aluminum oxide, silicon oxide, silicon oxynitride and silicon nitride in the same chamber. In this patent, the PEALD device is used for the TOPCon battery The silicon wafer 1 is deposited on the front side.

[0039] refer to figure 1 As shown, the photovoltaic cell surface passivation system of the present invention at least includes multifunctional PECVD equipment, annealing furnace and PEALD equipment, and the annealing furnace is located after the multifunctional PECVD process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com