Dexibuprofen lipid emulsion injection and preparation method thereof

A technology for preparation of injections and dexibuprofen, which is applied in the fields of emulsion delivery, pharmaceutical formulations, and medical preparations of non-active ingredients. It can solve problems such as injection pain, allergic reactions, and safety issues, and achieve pain relief and improve Safety, high drug loading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Take soybean oil, medium-chain triglycerides, glycerin, and water in appropriate amounts, add excess Dexibuprofen, and shake at room temperature for 24 hours to form a saturated solution. After centrifugation, take the supernatant oil layer and measure the solubility of Dexibuprofen.

Embodiment 2

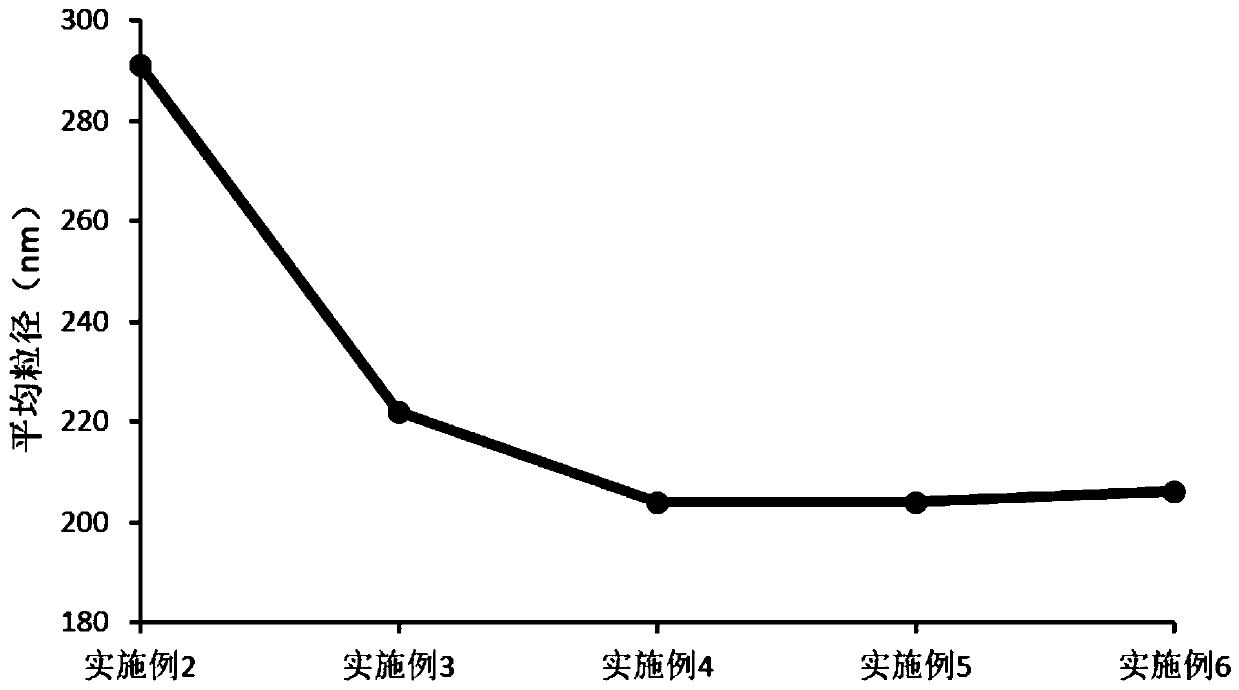

[0048]Weigh 20.0g of soybean oil and medium-chain triglycerides, mix and stir; add 151.0g of solubilizer KolliphorHS, heat to 50 degrees, and stir until completely dissolved; add 10.0g of ibuprofen, stir until completely dissolved, as Oil phase: take 100mL of water for injection, add 5.0g of glycerin, 2.4g of refined egg yolk lecithin, heat to 50 degrees, grind, stir until the solution is uniform, and use it as the water phase; mix the oil phase and water phase, shear, and stir until The solution is homogeneous and a primary emulsion is formed. Use a high-pressure homogenizer for homogenization, the homogenization pressure is 500 Bar, and the number of homogenization is 6 times. After the 5th homogenization, add water to make the volume to 200 mL. After homogenization, the solution was sterilized with damp heat at 121°C for 15 minutes to obtain Dexibuprofen fat emulsion injection.

Embodiment 3

[0050] Weigh 20.0g of soybean oil and medium-chain triglycerides, mix and stir; add 151.0g of solubilizer KolliphorHS, heat to 50 degrees, and stir until completely dissolved; add 10.0g of ibuprofen, stir until completely dissolved, as Oil phase: take 100mL of water for injection, add 5.0g of glycerin, 2.4g of refined egg yolk lecithin, heat to 50 degrees, grind, stir until the solution is uniform, and use it as the water phase; mix the oil phase and water phase, shear, and stir until The solution is homogeneous and a primary emulsion is formed. Use a high-pressure homogenizer for homogenization, the homogenization pressure is 600 Bar, and the number of homogenization is 6 times. After the 5th homogenization, add water to make the volume to 200 mL. After homogenization, the solution was sterilized with damp heat at 121°C for 15 minutes to obtain Dexibuprofen fat emulsion injection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com