A kind of preparation method of clopidogrel bisulfate solid preparation

A technology of clopidogrel hydrogen sulfate solid and clopidogrel hydrogen sulfate, which is applied in the field of biomedicine, can solve the problems such as the increase of impurities in the drug, the rapid increase of impurities, the unstable tablet dissolution, and the like, and can reduce the sticking time and the heating time. The effect of shortening and shortening the granulation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、4

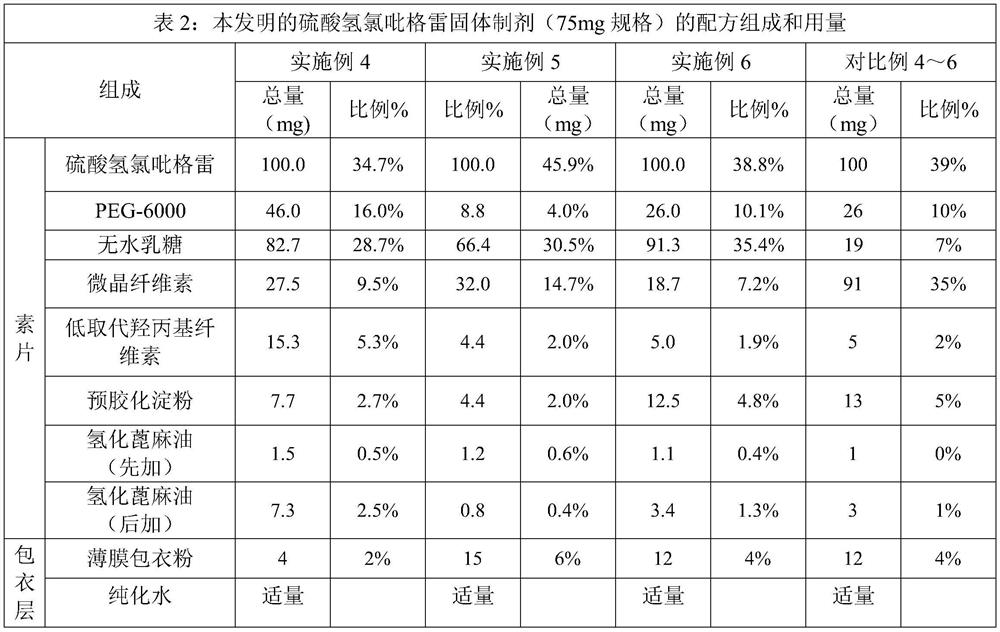

[0036] See Table 1 and Table 2 for the formula (in terms of each tablet);

[0037] The preparation method that adopts is as follows:

[0038] Step (1) Weigh clopidogrel bisulfate, anhydrous lactose, PEG-6000, microcrystalline cellulose, and low-substituted hydroxypropyl cellulose according to the formulas in Examples 1 and 4, and mix them uniformly to obtain the first mixture; Put the first mixture into the hot-melt granulation equipment, raise the temperature to 58°C, and keep it warm for 5 minutes to obtain the second mixture; cool the second mixture to 38°C, pass through a 16-mesh sieve for granulation, and obtain Granule A;

[0039] Step (2) Mix the granules A with the hydrogenated castor oil (added first) in the formulas of Examples 1 and 4 to obtain the third mixture, and use the dry press granulator to press the third mixture into granules, and the pressure of the rollers is set to 30bar, use a 1.5mm sieve to sieve to obtain granule B;

[0040] Step (3) Granule B is u...

Embodiment 2、5

[0042] See Table 1 and Table 2 for the formula (in terms of each tablet);

[0043] The preparation method that adopts is as follows:

[0044] Step (1) Weigh clopidogrel bisulfate, anhydrous lactose, PEG-6000, microcrystalline cellulose, and low-substituted hydroxypropyl cellulose according to the formulas in Examples 2 and 5, and mix them uniformly to obtain the first mixture; Put the first mixture into the hot-melt granulation equipment, raise the temperature to 70°C, and keep it warm for 15 minutes to obtain the second mixture; cool the second mixture to 25°C, pass through a 24-mesh sieve for granulation, and obtain Granule A;

[0045] Step (2) Mix the granule A with the hydrogenated castor oil (add first) of the formula amount of Example 2 and 5 to obtain the third mixture, and the third mixture is pressed into granules using a dry pressing granulator, and the pressure of the pressure wheel is set at 70bar. Sizing with a 1.0mm sieve to obtain granule B;

[0046] Step (3) ...

Embodiment 3、6

[0048] See Table 1 and Table 2 for the formula (in terms of each tablet);

[0049] The preparation method that adopts is as follows:

[0050] Step (1) Weigh clopidogrel bisulfate, anhydrous lactose, PEG-6000, microcrystalline cellulose, and low-substituted hydroxypropyl cellulose according to the formulas in Examples 3 and 6, and mix them uniformly to obtain the first mixture; Put the first mixture into the hot-melt granulation equipment, raise the temperature to 60°C, and keep it warm for 10 minutes to obtain the second mixture; cool the second mixture to 30°C, pass through a 20-mesh sieve for granulation, and obtain Granule A;

[0051] Step (2) Mix the granule A with the hydrogenated castor oil (add first) of the formula amount of Example 3 and 6 to obtain the third mixture, and the third mixture is pressed into granules using a dry pressing granulator, and the pressure of the pressure wheel is set at 50 bar. Sizing with a 1.2mm sieve to obtain granule B;

[0052] Step (3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com