Bubble control micro-ultrasonic sphere emission profiling array polishing method and device

A technology of grinding and polishing spheres, which is applied in the field of bubble-controlled micro-ultrasonic sphere emission profiling array grinding and polishing, can solve the problems of low shape accuracy, low processing efficiency, fast wear and so on, to ensure shape consistency, improve processing efficiency, surface The effect of low roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiment of the specific solution of the present invention will be further elaborated in conjunction with the accompanying drawings.

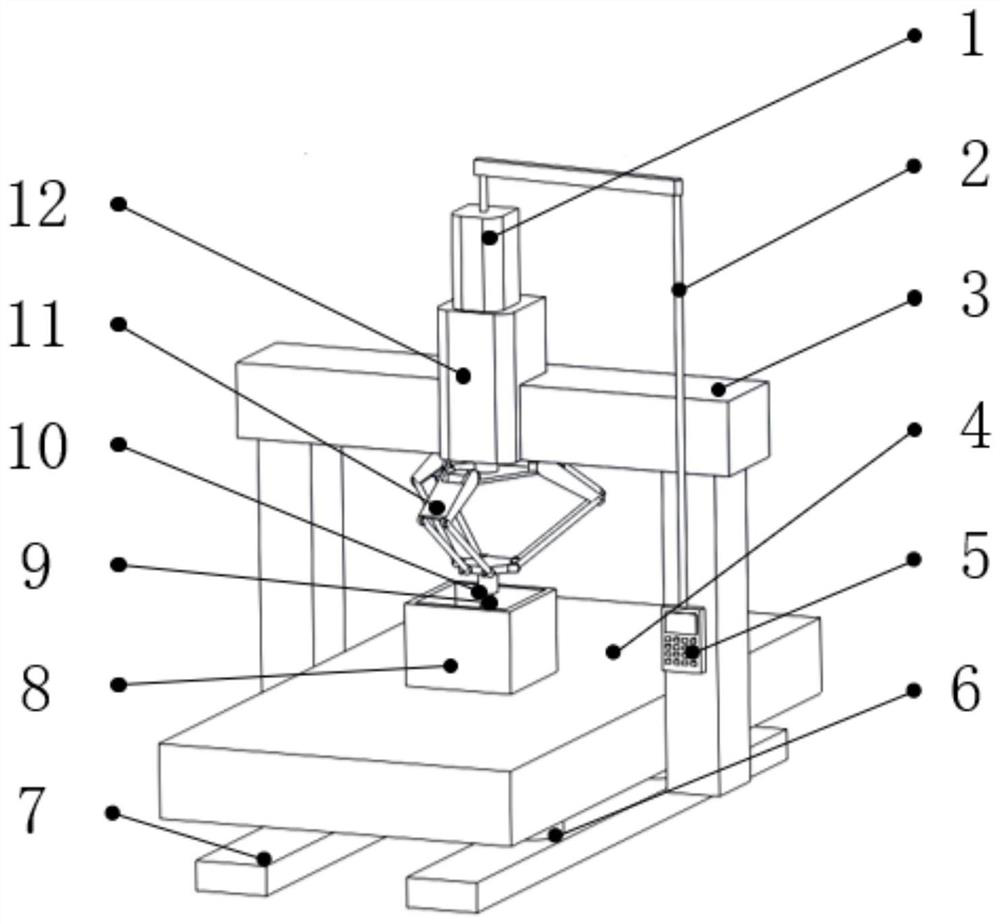

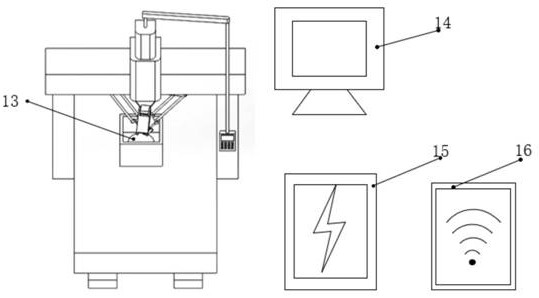

[0026] refer to Figure 1 to Figure 5 , a bubble control micro-ultrasonic sphere emission profiling array polishing method and device, the polishing method includes the following steps:

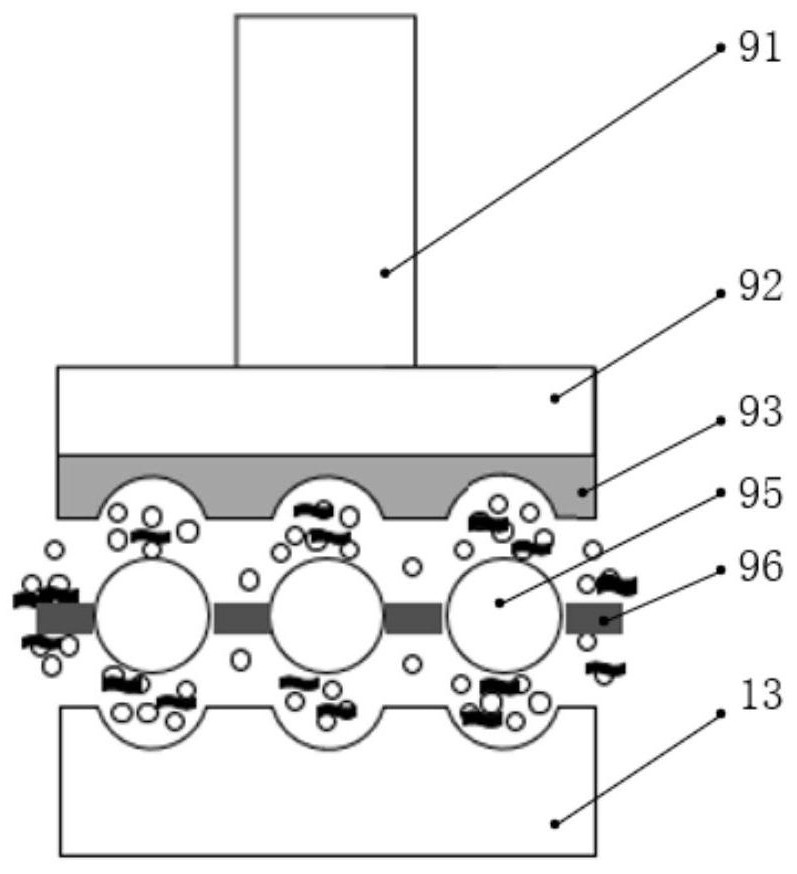

[0027] Make grinding and polishing mold 9: described grinding and polishing mold 9 comprises tool connecting rod shown in the figure, hard material coating 93 (this example adopts hard diamond coating), ball mold guide plate 96 (illustration is partly covered Split ball mold guide plate) and spheroid 95. The tool connecting rod includes a horn 91 at the upper end and a tool head 92 at the lower end, the upper end of the horn 91 is connected with the micro ultrasonic vibration device 10, and the tool head 92 is plated with a hard material with a thickness of 5 mm The coating 93 is made of aluminum oxide material in this example, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com