Side loading device, control system and method of bucket loading mechanism, garbage truck

A control system and technology for garbage trucks, which are applied in the field of holding buckets, can solve the problems of inability to quickly and accurately adjust the positions of the swing arm and the holding claw, and prone to misoperation, so as to achieve good maneuverability, improve work efficiency, and improve work efficiency. good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

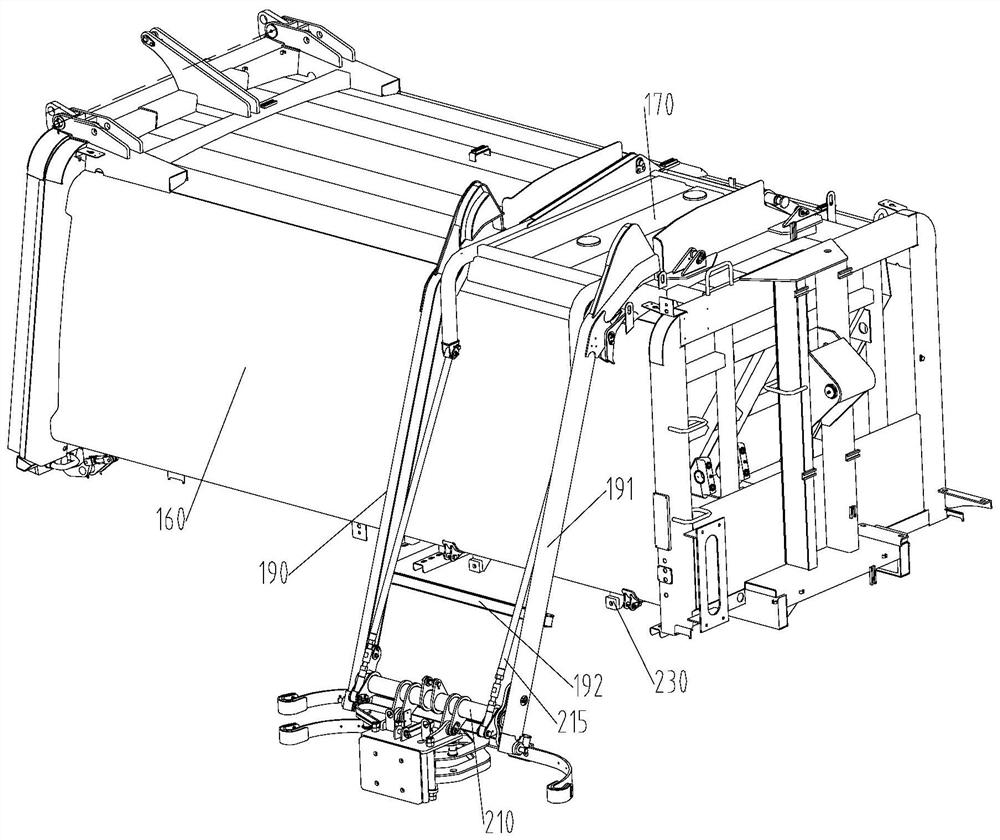

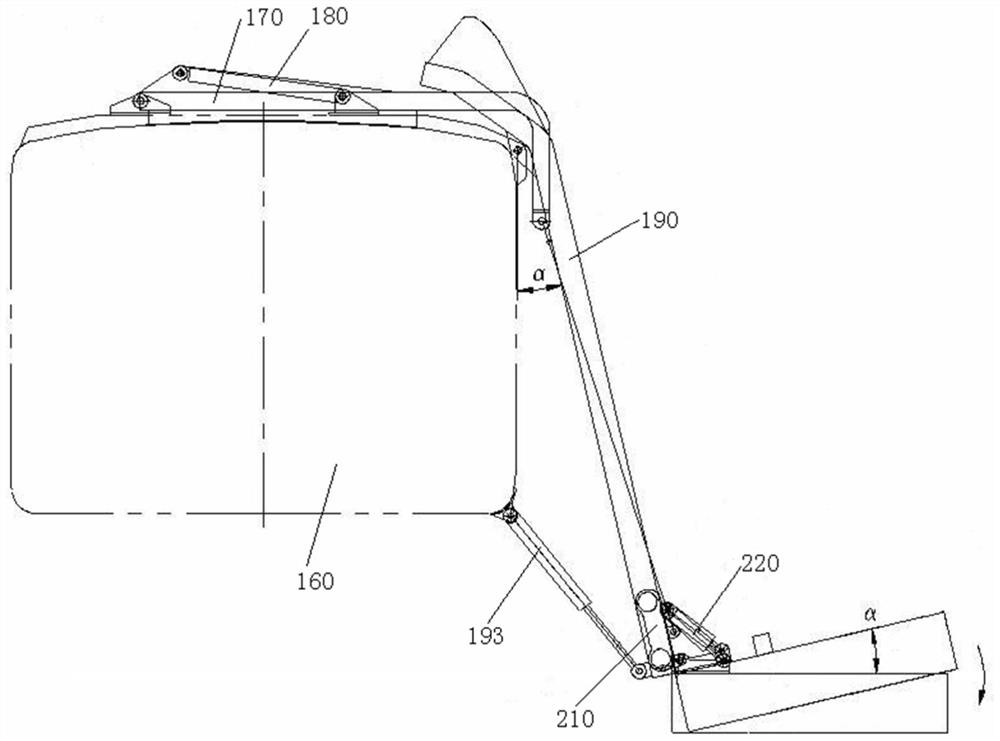

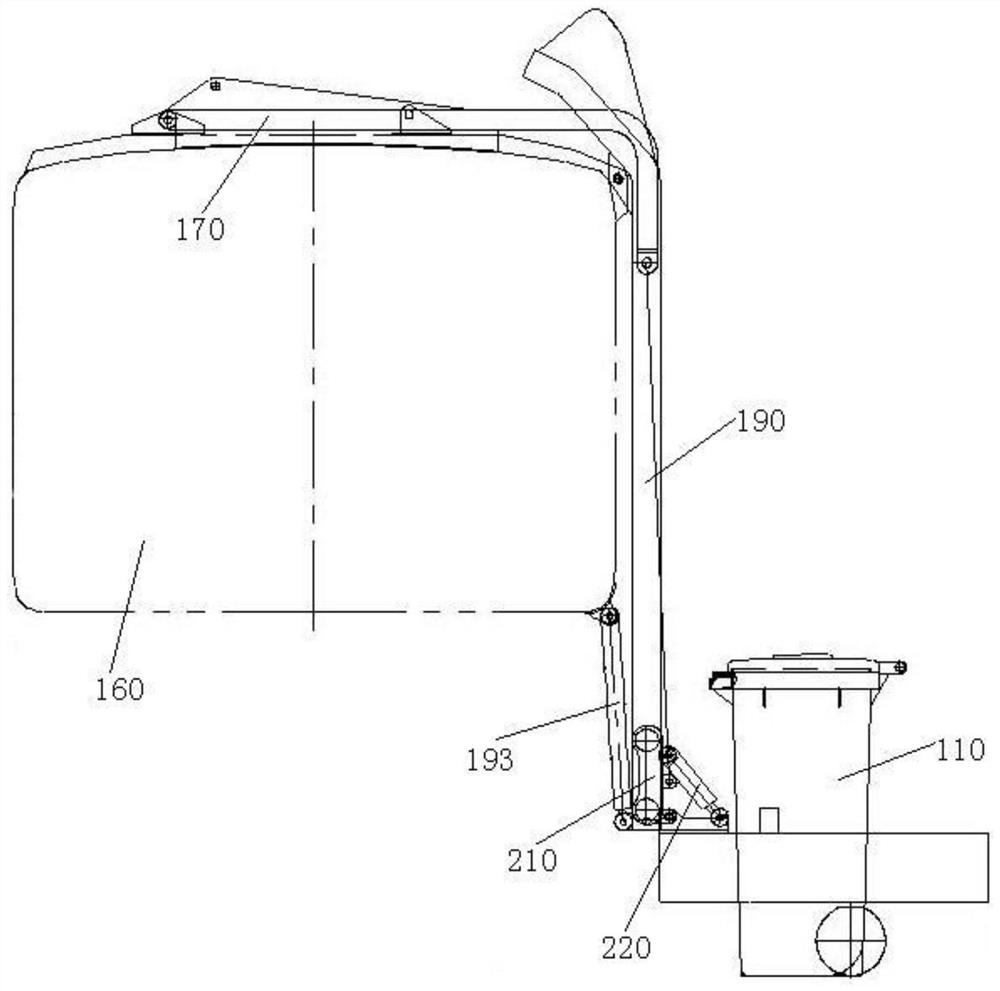

[0056] Such as figure 1 with figure 2 As shown, the first embodiment of the present invention provides a side feeding device, which is connected to one side of the garbage bin 160 on the garbage truck. The top cover 170 of mouth, the first end of top cover 170 is hinged with the top plate of dustbin 160, and top cover 170 is connected to be used to drive top cover 170 to rotate around the hinge point that is hinged with the top plate of dustbin 160 to open or close the feeding port The first driving mechanism 180 is connected with the control device of the garbage truck. The side loading device also includes a slide rail mechanism 190 hinged on one side of the dustbin 160, the slide rail mechanism 190 is connected with the control device to rotate around the hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com