Sedimentation tank for water treatment

A sedimentation tank, water treatment technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, filtration treatment, etc., can solve interference, slow down the speed of flocculation and gravitational sedimentation, stirring and mixing effect Poor and other problems, to achieve the effect of accelerating aggregation and decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

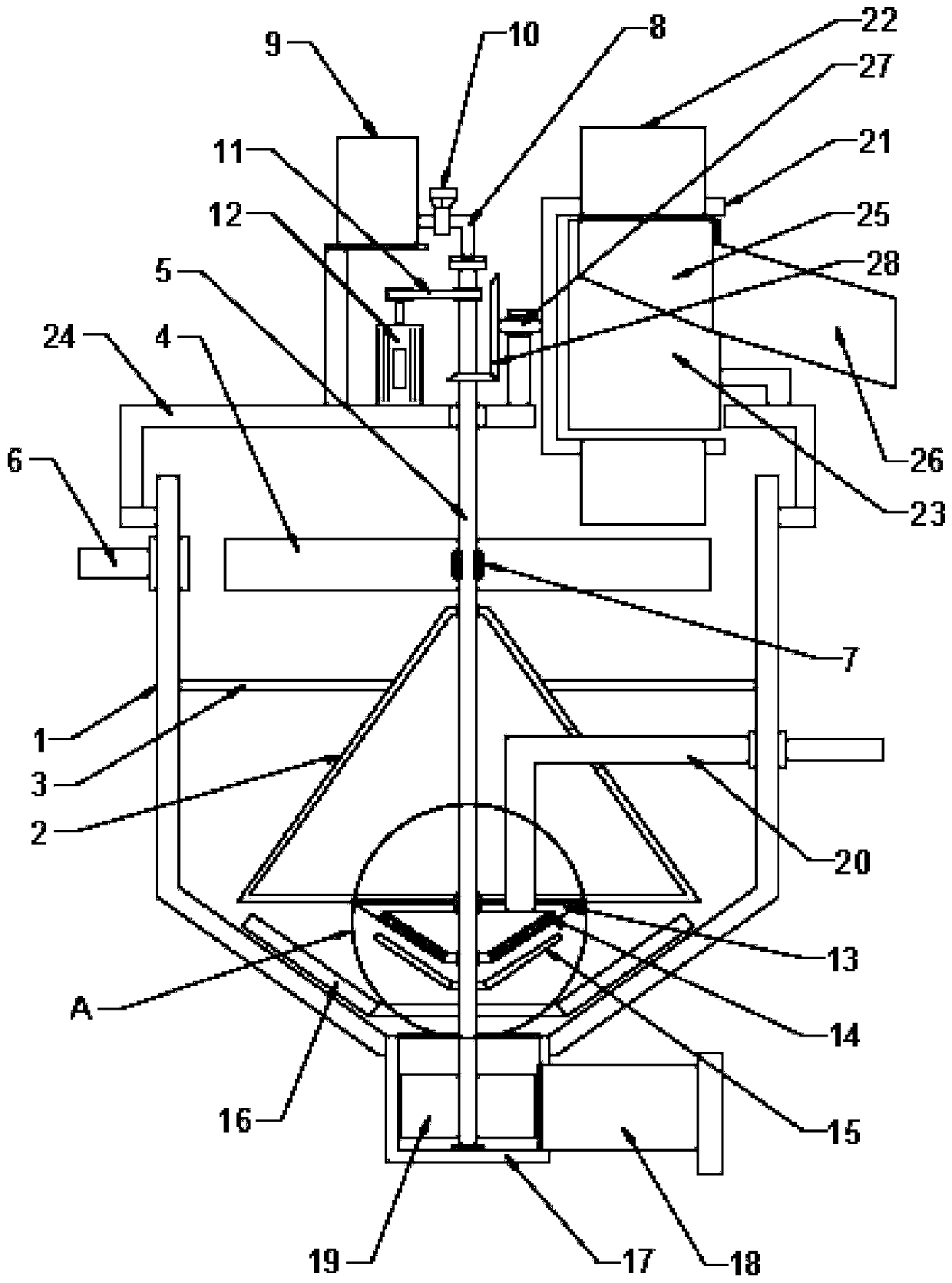

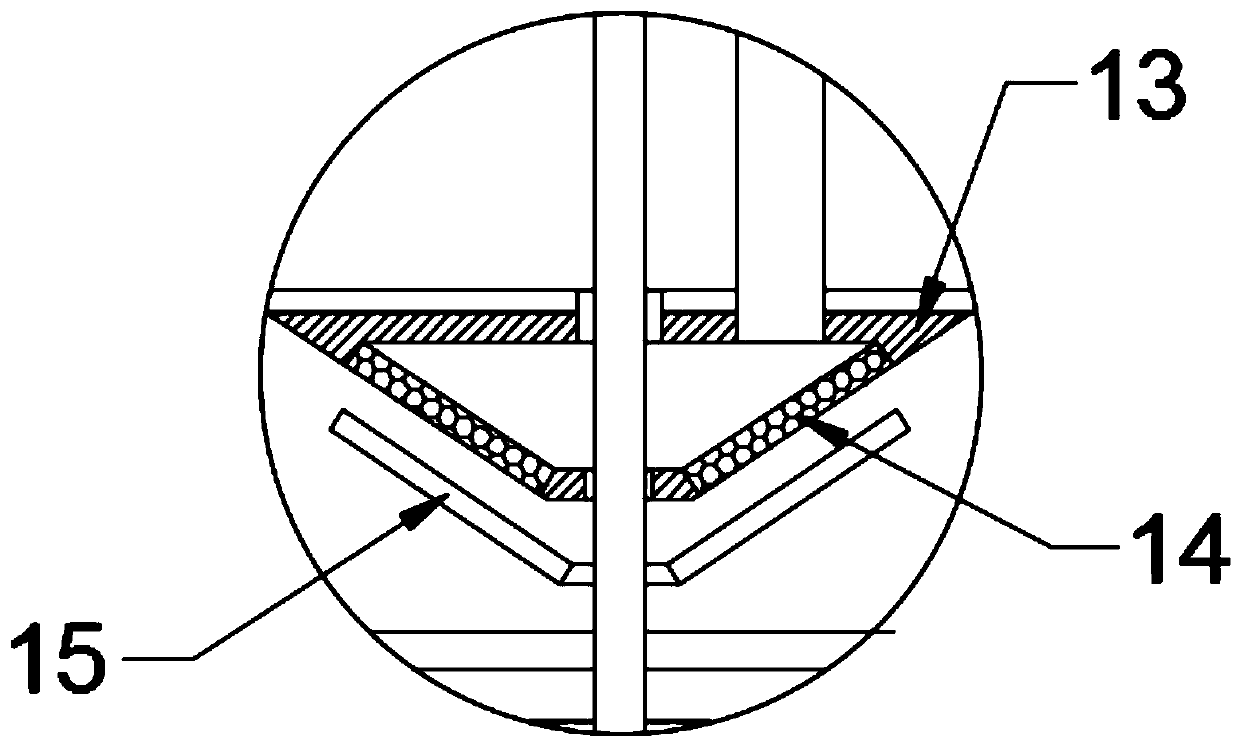

[0024] see Figure 1-5 , in an embodiment of the present invention, a sedimentation tank for water treatment includes a tank body 1; a conical cylinder 2 is arranged inside the tank body 1, and the conical cylinder 2 is fixedly connected to the inner wall of the tank body 1 through a fixing rod 3; Above the conical cylinder 2, there are agitating plates 4 distributed in a circle. The agitating plates 4 are fixedly connected with a rotating shaft 5, and the rotating shaft 5 extends to the top of the pool body 1 and is connected with a driving motor 12 through a transmission belt 11. The driving motor 12 is fixedly connected with a Bridge frame 24, bridge frame 24 is fixedly connected with pool body 1; Nozzle 7 is arranged between said stirring plate 4, Nozzle 7 is fixedly connected with rotating shaft 5, An infusion tube 8 is nested in the rotating shaft 5, The lower end of the infusion tube 8 communicates with the nozzle 7 , the infusion tube 8 extends to the top of the rotati...

Embodiment 2

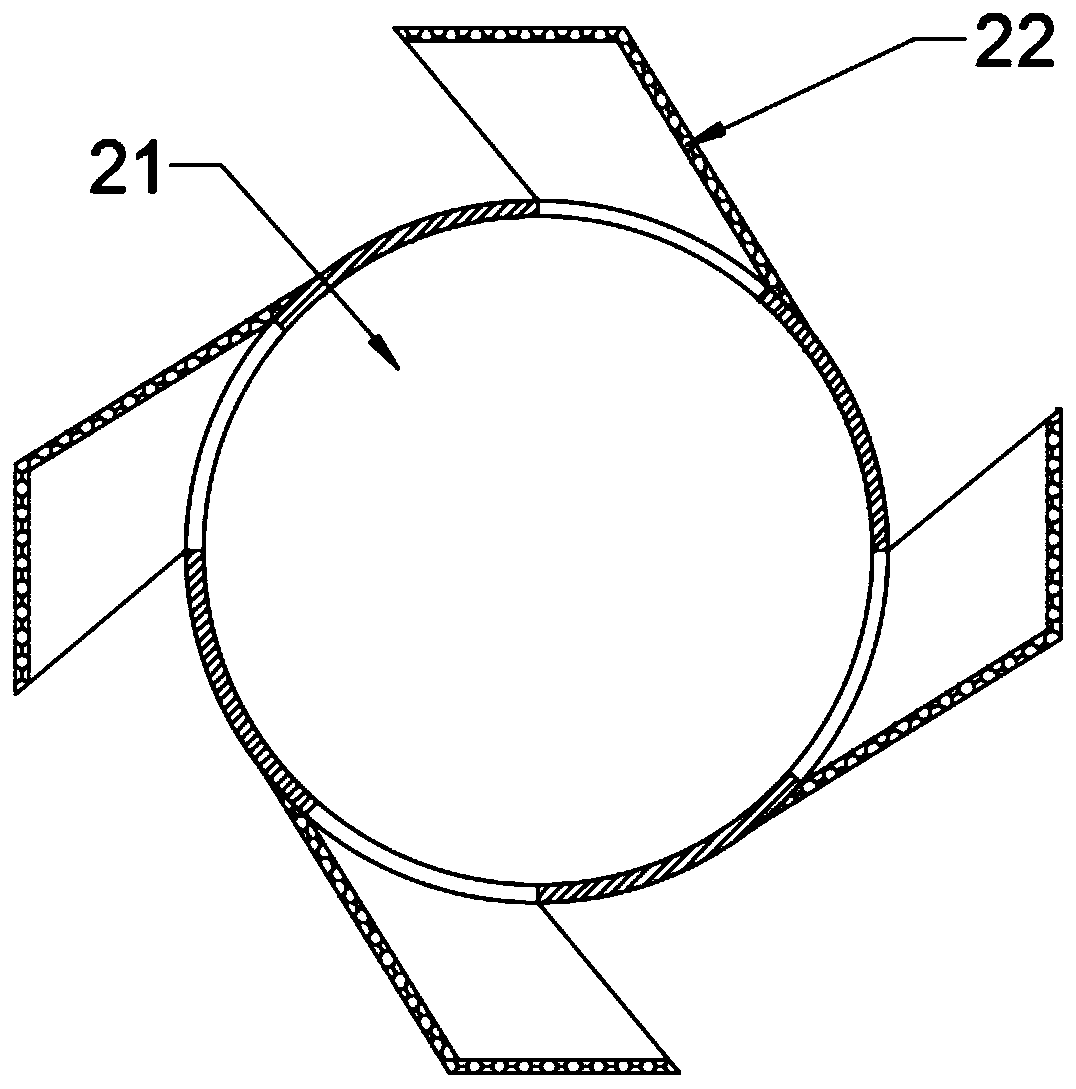

[0029] The difference between this embodiment and Embodiment 1 is that a salvage mechanism is provided on the upper part of the pool body 1, and the salvage mechanism includes an overshot cylinder 21, which is a cylindrical cylinder with an opening at one end, and the overshot cylinder 21 is fixedly connected with salvage cylinders distributed in a circle. Bucket 22, the salvage bucket 22 is a metal mesh bucket, and the salvage bucket 22 communicates with the salvage barrel 21; the salvage barrel 21 is nested with a fixed cylinder 23 and is rotatably connected with the fixed cylinder 23, and the fixed cylinder 23 is fixedly connected with the bridge frame 24; A blanking chamber 25 is provided on the upper part of the fixed cylinder 23, and the blanking chamber 25 is connected with a slag discharge pipe 26.

[0030] The overshot 21 is fixedly connected with a transmission shaft 27, and the transmission shaft 27 is connected and driven with the rotating shaft 5 through a transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com