Aging-resistant ceramic insulator and preparation method thereof

A ceramic insulator, anti-aging technology, applied in the direction of insulators, electrical components, circuits, etc., can solve the problems of accelerated aging rate, pollution flashover, ice flashover, etc., and achieve the effects of reducing aging rate, good reflection, and improving cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

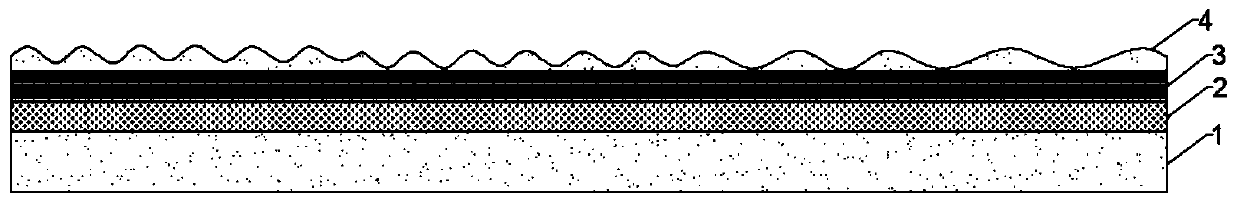

[0033] Such as figure 1 As shown, an aging-resistant ceramic insulator includes a zirconia substrate 1. The zirconia substrate 1 is sequentially provided with a 2mm adsorption layer 2, a 1mm hydrophobic layer 3, and a 1mm reflective layer 4 from the inside to the outside. The reflective layer is wavy. shape, during specific implementation, adopt a mold with a wavy shape to fix the mould, or other methods of the prior art to be coated in a wavy shape;

[0034] A method for preparing the aging-resistant ceramic insulator as described above, comprising the following steps:

[0035] S1: Preparation of zirconia matrix 1: 8 parts of kaolin, 3 parts of quartz ore, 2 parts of hydromica, 40 parts of boehmite, 10 parts of zircon, 5 parts of feldspar, and 3 parts of waste porcelain in parts by weight Add a ball mill to grind for 2 hours, and pass through a 100-mesh sieve to obtain a zirconia matrix powder;

[0036] S2: Prepare bonding solution: Add 1 part of carboxymethyl cellulose to ...

Embodiment 2

[0046] Such as figure 1 As shown, an aging-resistant ceramic insulator includes a zirconia substrate 1. The zirconia substrate 1 is provided with a 3mm adsorption layer 2, a 2mm hydrophobic layer 3, and a 1mm reflective layer 4 in sequence from the inside to the outside. The reflective layer is a wave shape;

[0047] A method for preparing the aging-resistant ceramic insulator as described above, comprising the following steps:

[0048] S1: Preparation of zirconia matrix 1: 10 parts of kaolin, 5 parts of quartz ore, 6 parts of hydromica, 45 parts of boehmite, 12 parts of zircon, 8 parts of feldspar, and 4 parts of waste porcelain in parts by weight Add a ball mill to grind for 3 hours, and pass through a 150-mesh sieve to obtain a zirconia matrix powder;

[0049] S2: Preparation of bonding solution: Add 2 parts of carboxymethyl cellulose to 90 parts of acetone, then add it to the zirconia matrix powder by high-pressure spraying method, and stir at the same time at a stirring...

Embodiment 3

[0059] Such as figure 1 As shown, an aging-resistant ceramic insulator includes a zirconia substrate 1. The zirconia substrate 1 is sequentially provided with a 4mm adsorption layer 2, a 3mm hydrophobic layer 3, and a 2mm reflective layer 4 from the inside to the outside. The reflective layer is a wave shape;

[0060] A method for preparing the aging-resistant ceramic insulator as described above, comprising the following steps:

[0061] S1: Preparation of zirconia matrix 1: 12 parts of kaolin, 7 parts of quartz ore, 9 parts of hydromica, 50 parts of boehmite, 15 parts of zircon, 10 parts of feldspar, and 5 parts of waste porcelain in parts by weight Add a ball mill to grind for 4 hours, and pass through a 200-mesh sieve to obtain a zirconia matrix powder;

[0062] S2: Preparation of bonding solution: Add 2 parts of carboxymethyl cellulose to 90 parts of acetone, then add it to the zirconia matrix powder by high-pressure spraying method, and stir at the same time at a stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com