Thermo-sensitive ionic imprinting polymer for separating high rhenium acid radical ions and preparation method and application of thermo-sensitive ionic imprinting polymer

A temperature-sensitive polymer, perrhenate technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of difficult to improve adsorption and desorption performance at the same time, limited application, inflexibility, etc., to improve the low desorption rate. and low reusability, simple preparation method, precise and efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

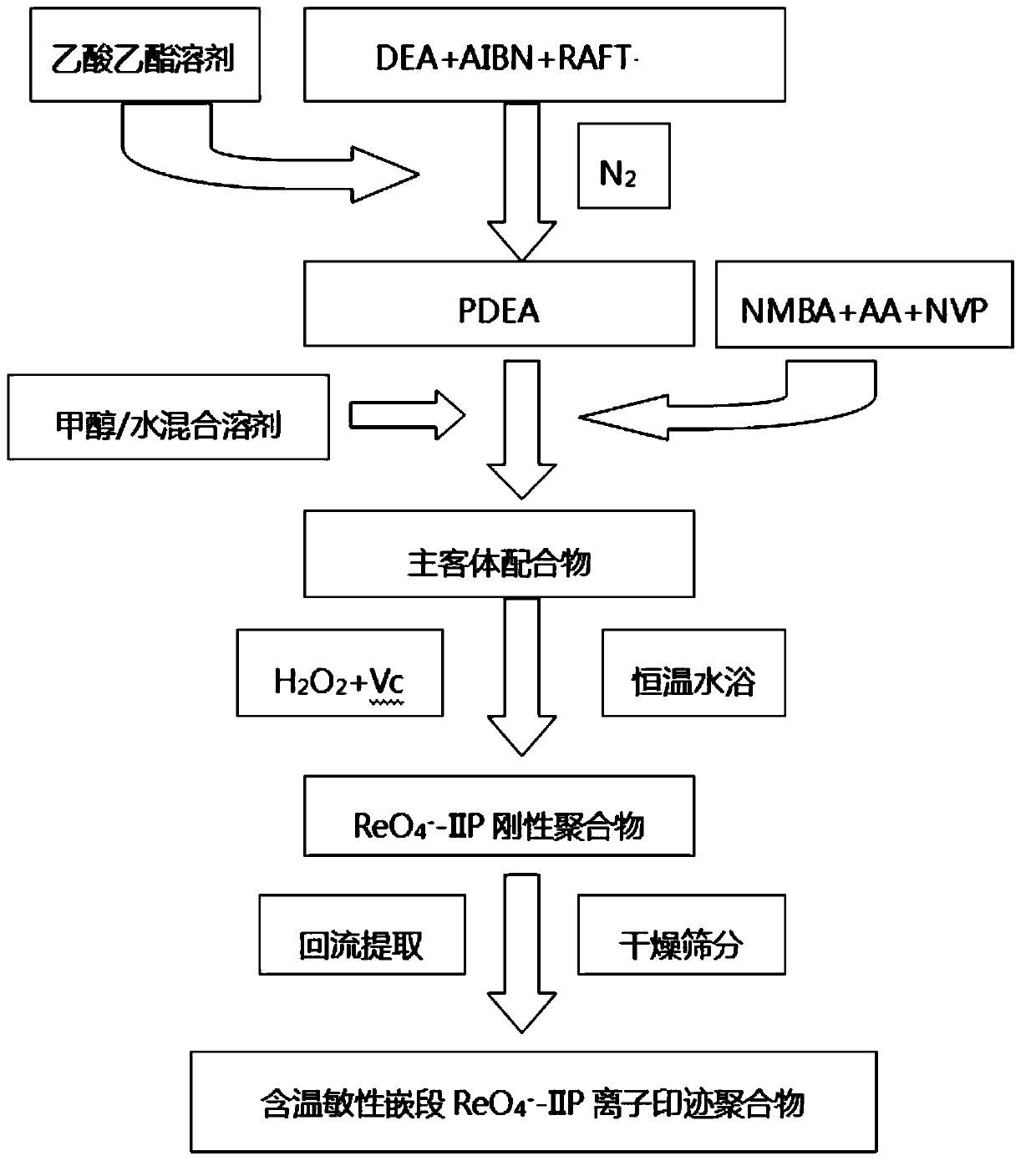

Method used

Image

Examples

Embodiment 1

[0028] (1) Weigh 10mmol of N,N-diethylbisacrylamide (DEA), and azobisisobutyronitrile (AIBN) and trithiododecanoic acid-2-carboxyisopropyl ester reagent (RAFT) Mix according to a certain ratio, and use ethyl acetate as a solvent to prepare a solution. Wherein: the molar ratio of AIBN, RAFT reagent and DEA is 1:20:1000, and the mass percent concentration of the prepared solution is 40%. N in the solution 2 After 15 minutes, the mixture was stirred and reacted in an oil bath at 70° C. for 20 hours to obtain a thermosensitive polymer poly-N,N-diethylacrylamide (PDEA) with a molecular weight of 3600.

[0029] (2) Weigh 0.15 g of the temperature-sensitive polymer PDEA prepared in step (1), add it into 30 mL of methanol / water (volume ratio 60:40) mixed solvent to dissolve, and obtain a mixed solution containing the temperature-sensitive polymer.

[0030](3) Add 30mmolN, N-methylenebisacrylamide (NMBA) into the mixed solvent containing thermosensitive polymer obtained in step (2)....

Embodiment 2

[0033] (1) Weigh 10 mmol of N,N-diethylbisacrylamide (DEA), and azobisisobutyronitrile (AIBN) and trithiododecanoic acid-2-carboxyisopropyl ester reagent (RAFT) Mix according to a certain ratio, and use ethyl acetate as a solvent to prepare a solution. Wherein: the molar ratio of AIBN, RAFT reagent and DEA is 1:30:2000, with ethyl acetate as solvent, prepared the solution of 45% (mass percentage concentration), pass N 2 After 15 minutes, stir and react in an oil bath at 65°C for 16 hours to obtain a temperature-sensitive polymer poly-N,N-diethylacrylamide (PDEA)

[0034] (2) Weigh 0.2 g of the temperature-sensitive polymer PDEA prepared in step (1), add it to 40 ml of methanol / water (volume ratio 70:30) and dissolve it in a mixed solvent to obtain a mixed solution containing the temperature-sensitive polymer

[0035] (3) Add 40mmol N,N-methylenebisacrylamide (NMBA) into the mixed solution containing temperature-sensitive polymer obtained in step (2). After the NMBA is comple...

Embodiment 3

[0038] (1) Weigh 20mmol of N,N-diethylbisacrylamide (DEA), and azobisisobutyronitrile (AIBN) and trithiododecanoic acid-2-carboxyisopropyl ester reagent (RAFT) Mix according to a certain ratio, and use ethyl acetate as a solvent to prepare a solution. Wherein: the mol ratio of AIBN, RAFT reagent and DEA is 1:40:4000, is solvent with ethyl acetate, has prepared the solution of 40% (mass percentage concentration), passes N 2 After 12 minutes, the mixture was stirred and reacted in an oil bath at 70° C. for 20 hours to obtain a thermosensitive polymer poly-N,N-diethylacrylamide (PDEA) with a molecular weight of 3600.

[0039] (2) Weigh 0.15 g of the temperature-sensitive polymer PDEA prepared in step (1), add it to 300 ml of methanol / water (volume ratio 70:30) mixed solvent to dissolve, and obtain a mixed solution containing the temperature-sensitive polymer.

[0040] (3) Add 35mmol N,N-methylenebisacrylamide (NMBA) into the mixed solution containing temperature-sensitive polym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com