Method for storing carbon dioxide gas in goaf filled with porous medium

A carbon dioxide and porous medium technology, applied in fillings, mining devices, mining equipment, etc., can solve the problems of not considering the storage of carbon dioxide gas, complex processes, ecological environment hazards, etc., to save preparation and transportation costs, simplify storage processes, Ensure long-term stable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

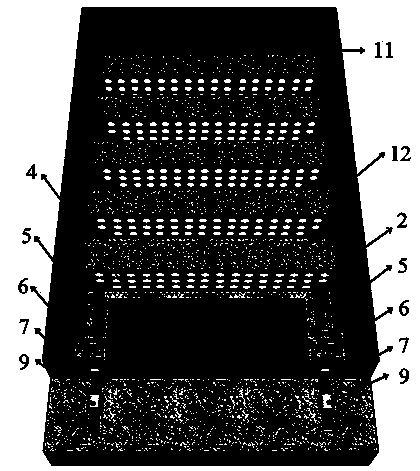

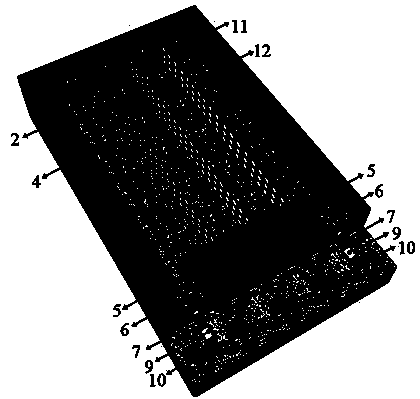

[0025] In the figure, the operation steps of the method for storing carbon dioxide gas in the goaf filled with porous media are as follows.

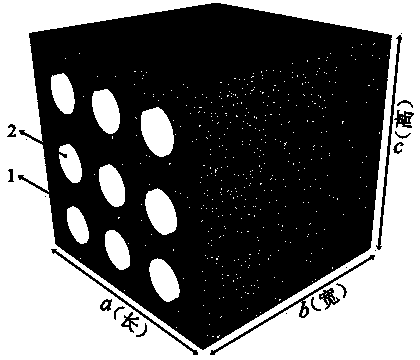

[0026] ① Mix crushed gangue, fly ash and cement in a certain proportion, add water and stir to form a paste material, then pour the paste material into a special mold to make a square porous medium 1, and let it dry and harden. Form the basic filling unit.

[0027] ② When the coal seam 3 is mined in the underground coal mine, the square porous medium 1 is used to build the filling strip 12 following the coal mining face in the goaf 4 to form an effective support for the newly exposed goaf roof strata, ensuring that the roof strata Integrity and stability; at the same time, carbon dioxide gas pressure injection pipes 7 are pre-buried on both sides of the goaf.

[0028] ③ After the mining of the working face in this section is completed, build the sealing wall 6 along the mining area to form a closed space in the gob;

[0029] ④ Collect ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com