Method of screening irradiation-damage-resistant material by utilizing gradient structure

A gradient structure, radiation-resistant technology, applied in the direction of analyzing materials, testing material hardness, and preparing samples for testing, etc., can solve the problems of time-consuming and low experimental efficiency, save money and time, improve efficiency, and improve testing The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

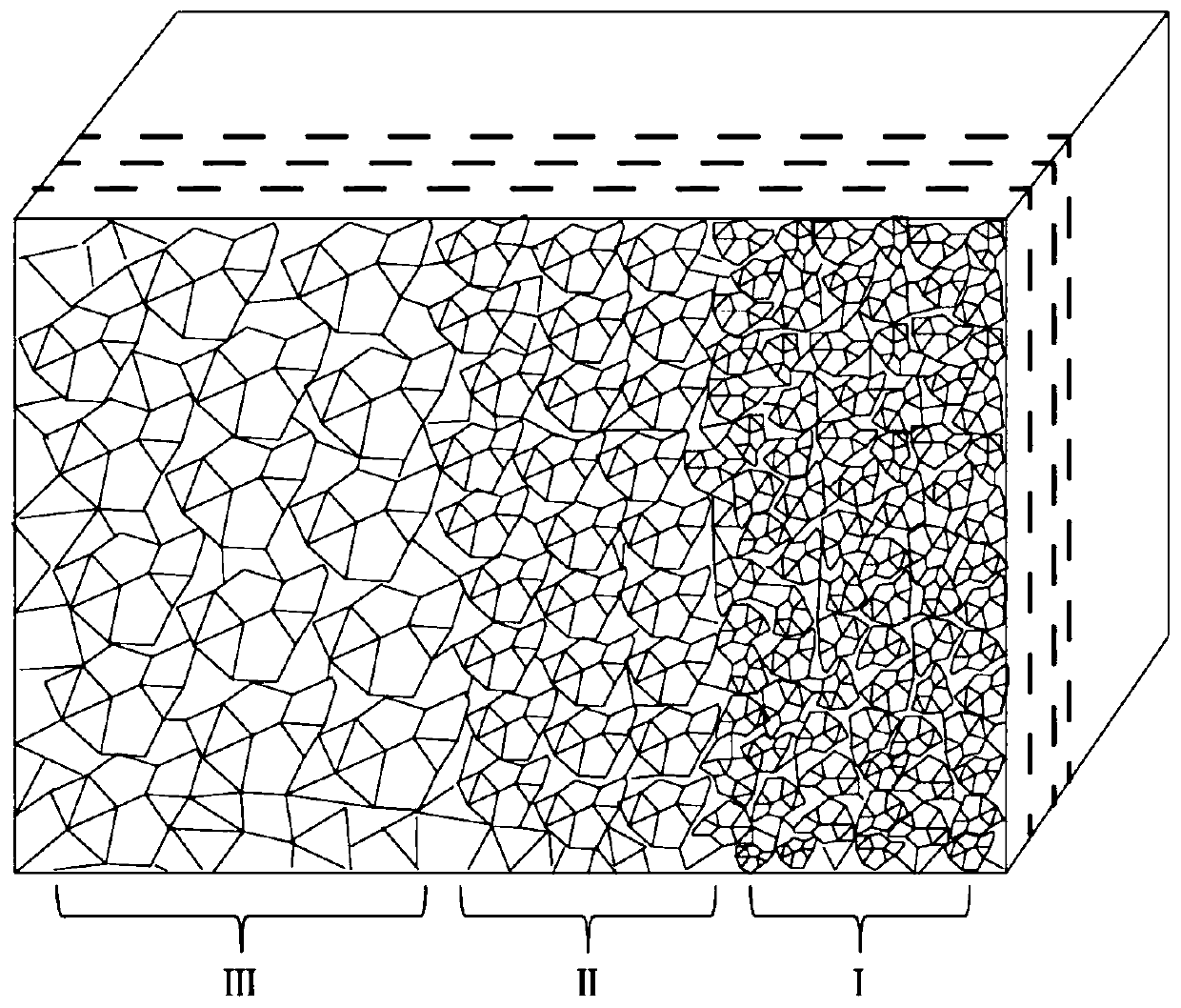

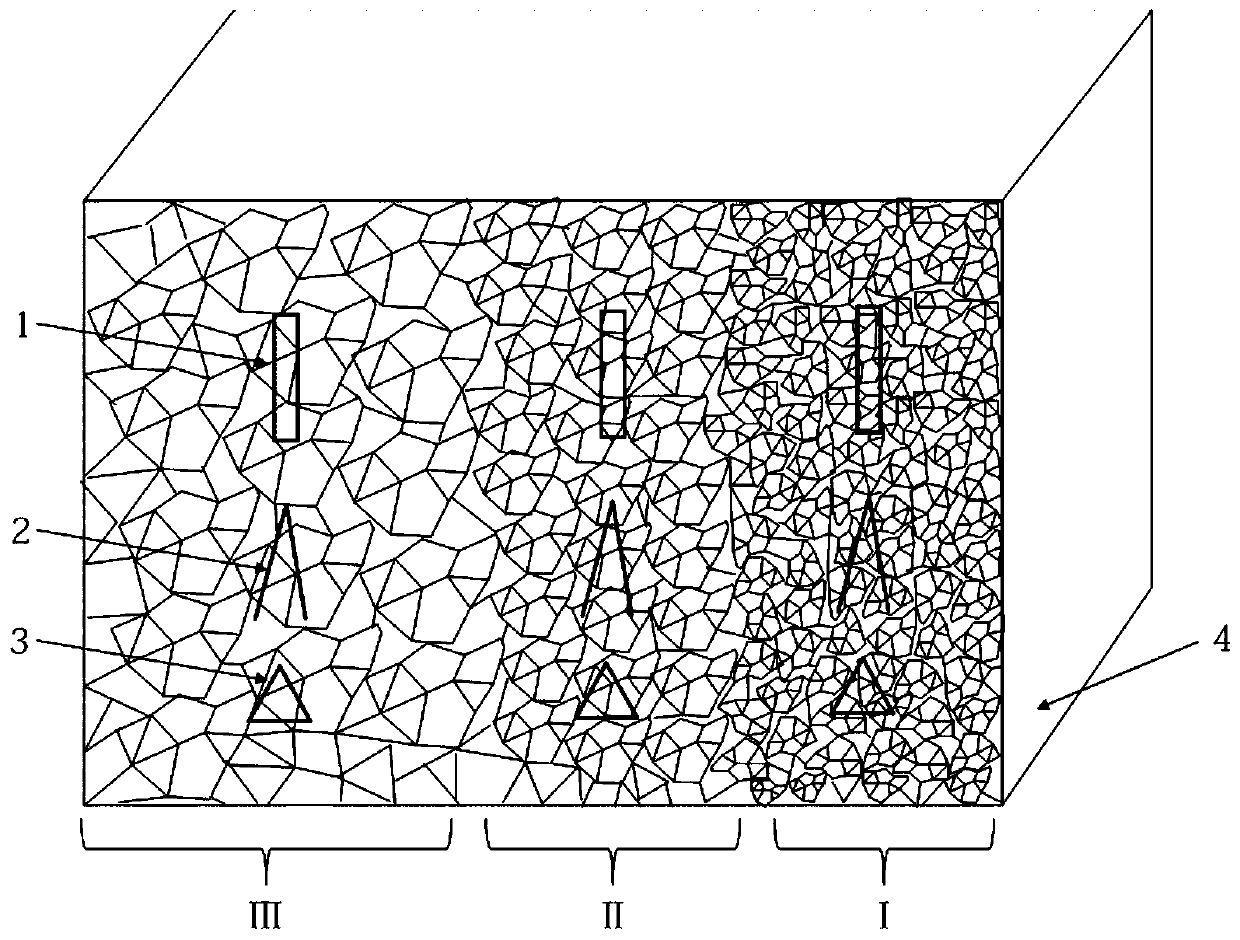

[0038] The purpose of the present invention is to provide an experimental method for screening radiation-resistant materials using gradient structures, so as to reduce the number of experimental samples and improve the efficiency of material microstructure characterization, thereby improving the efficiency of screening radiation-resistant materials.

[0039] The method scheme that realizes the object of the present invention comprises the following steps:

[0040] Step 1: Polish the cutting marks on the surface of the plate sample and its surroundings.

[0041] Step 2: Make sure the diameter of the marble is 1mm and the speed is 70m / s. .

[0042] Step 3: Clamp the sample into the surface nanometerized equipment (rotary shot peening equipment), add marbles with a diameter of 1mm, start the equipment, wait for the speed to reach 70m / s, and start peening the sample until it reaches the treatment It took 10 minutes to stop the processing and take out the sample. After the proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com