Device and a method for determining carbon deposition rate of catalytic reforming catalyst

A catalytic reforming and catalyst technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of reducing the carbon deposition rate of catalytic reforming catalysts, cannot judge, and the carbon deposition rate of catalysts varies greatly, so as to reduce the size , reduce impact, and determine the effect of accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

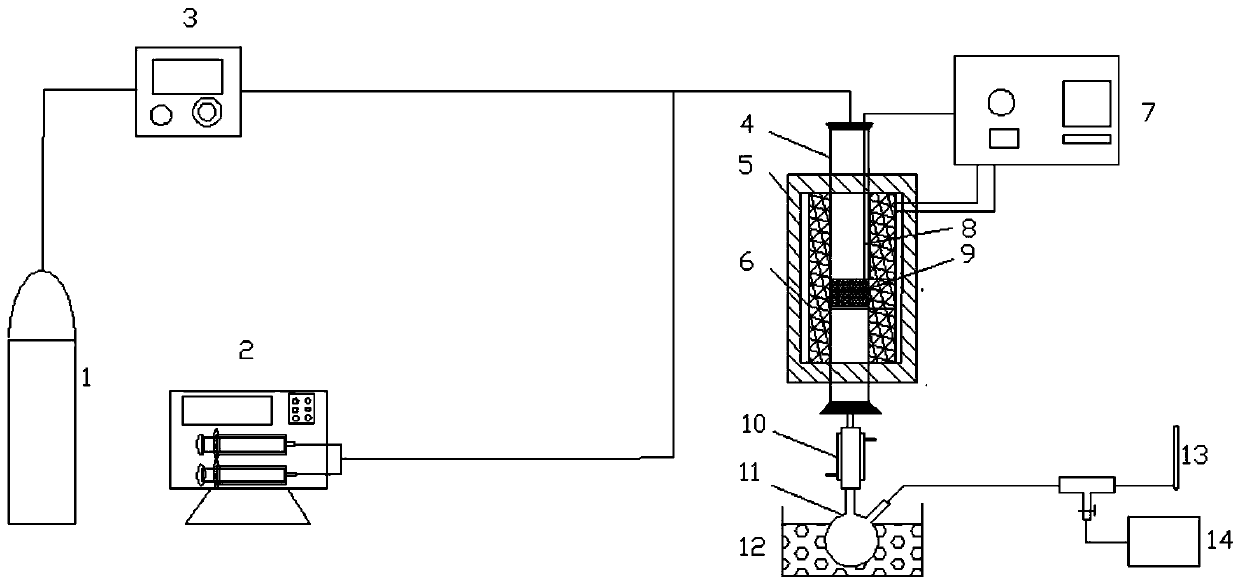

[0047] In this example, in order to study whether adding hydrogen peroxide in the reforming reactant water vapor can reduce the carbon deposition rate of the catalytic reforming catalyst during the hydrogen production process of the steam reforming of tar, a method for measuring the carbon deposition rate of the catalytic reforming catalyst is adopted. device, its structure diagram is shown in figure 1 , including: gas supply system, feed system, reaction system, product analysis system, electric heating control system;

[0048] Described gas supply system comprises nitrogen cylinder 1 and gas flowmeter 3;

[0049] The feed system includes a dual-channel micro-injection pump 2; in the dual-channel micro-injection pump 2, biomass tar is injected into the first channel, and water and hydrogen peroxide mixture are injected into the second channel; wherein, the mass of hydrogen peroxide accounts for The mass percentage of water and hydrogen peroxide mixture is 3%.

[0050] Descr...

Embodiment 2

[0079] A device for measuring the carbon deposition rate of a catalytic reforming catalyst, the same as Experimental Example 1.

[0080] A method for measuring the carbon deposition rate of a catalytic reforming catalyst, using the above-mentioned device, comprising the following steps:

[0081] (1) the catalytic reforming catalyst is loaded on the distribution net 9 in the quartz tube reactor 4;

[0082] (2) Nitrogen cylinder 1 is opened, nitrogen gas flow rate 1-10L / min is controlled by gas flowmeter 3, and the environment in quartz tube reactor 4 is purged to inert atmosphere;

[0083] (3) The electric heating temperature controller 7 is set as the reaction temperature, and the electric heating tube 6 heats the quartz tube reactor 4. After the temperature of the quartz tube reactor 4 reaches the reaction temperature, the nitrogen gas is adjusted by the gas flow meter 3 Flow 0.2-0.5L / min;

[0084] (4) After the tar and water of the double-channel micro-injection pump 2 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com