Carbon nanodot-modified bismuth tungstate photocatalyst, and preparation method and application thereof

A technology of carbon nano-dots and photocatalysts, applied in nano-optics, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of few reaction sites, bismuth tungstate cannot reach the theoretical threshold of photoelectric conversion, etc. It achieves the effects of simple preparation process, broadening the photoresponsivity and light absorption ability of visible light, and high photogenerated electron transfer ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

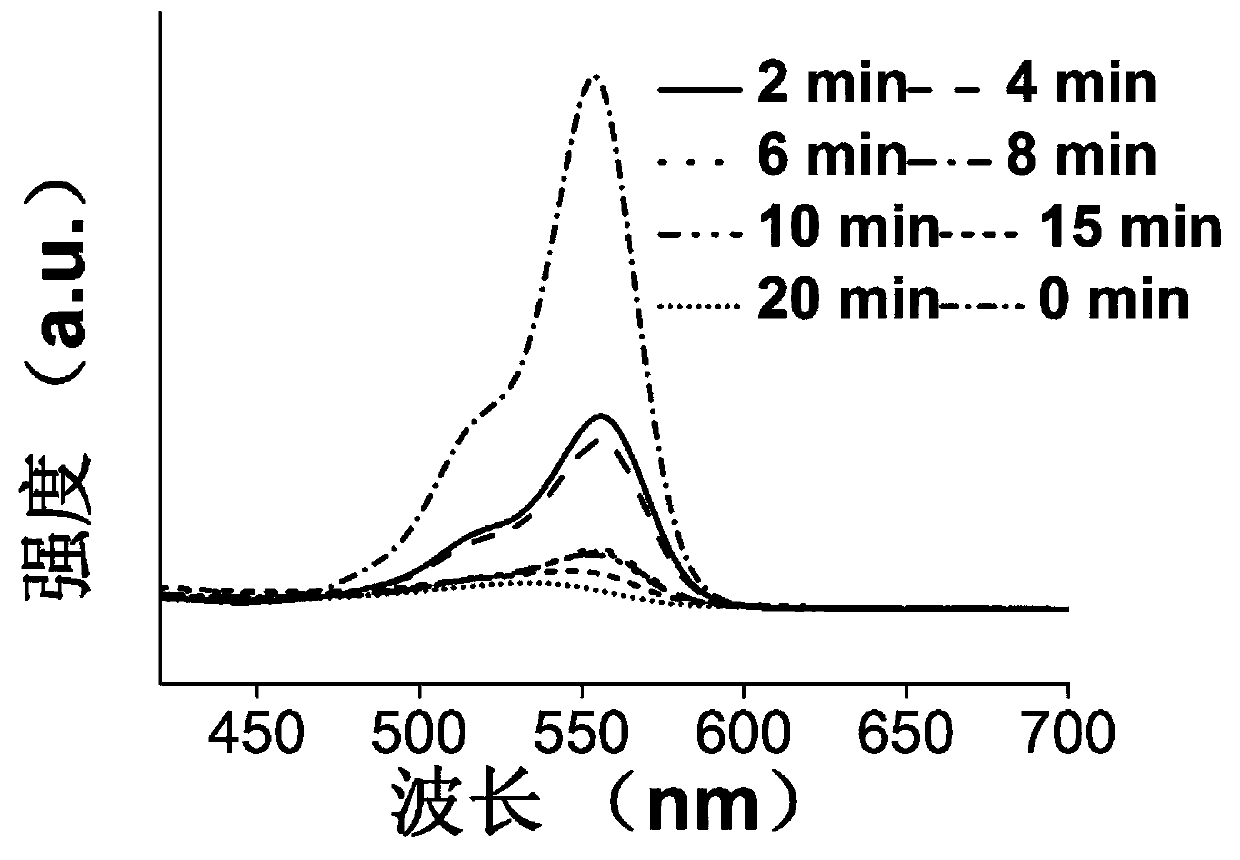

Image

Examples

Embodiment 1

[0032] 1. Dissolve 1.5mmol of bismuth tungstate dihydrate in 10ml of deionized water, and sonicate until completely dissolved to prepare a sodium tungstate precursor.

[0033] 2. Take 1.5 mmol of bismuth nitrate pentahydrate and dissolve it in 10 ml of dilute nitric acid solution with pH=6, and sonicate until completely dissolved to prepare a bismuth nitrate precursor.

[0034] 3. Mix 10ml of sodium tungstate precursor solution with 10ml of bismuth nitrate precursor solution to obtain a milky white bismuth tungstate precursor solution, transfer it to a 50ml high-temperature reaction kettle, and conduct a hydrothermal reaction at 120°C for 2 hours. After the hydrothermal treatment, the sediment was washed 5 times with deionized water. The washed sediment was placed in a quartz dish, transferred to a muffle furnace, and sintered at 450° C. for 2 h in an air atmosphere. After sintering, grind to obtain powdered bismuth tungstate powder.

[0035] 4. The carbon nano-dot solution i...

Embodiment 2

[0040] 1. Dissolve 5mmol of bismuth tungstate dihydrate in 10ml of deionized water, and sonicate until completely dissolved to prepare a sodium tungstate precursor.

[0041] 2. Dissolve 1 mmol of bismuth nitrate pentahydrate in 10 ml of dilute nitric acid solution with pH=6, and sonicate until completely dissolved to prepare a bismuth nitrate precursor.

[0042] Mix 3.5ml sodium tungstate precursor solution with 10ml bismuth nitrate precursor solution to obtain milky white bismuth tungstate precursor solution, transfer it to a 50ml high-temperature reaction kettle, and conduct a hydrothermal reaction at 100°C for 5 hours. After the hydrothermal treatment, the sediment was washed 5 times with deionized water. The washed sediment was placed in a quartz dish, transferred to a muffle furnace, and sintered at 400° C. for 4 h in an air atmosphere. After sintering, grind to obtain powdered bismuth tungstate powder.

[0043] 4. The carbon nano-dot solution is prepared by a simple hyd...

Embodiment 3

[0046] 1. Dissolve 1.mmol of bismuth tungstate dihydrate in 10ml of deionized water, and sonicate until completely dissolved to prepare a sodium tungstate precursor.

[0047] 2. Dissolve 5 mmol of bismuth nitrate pentahydrate in 10 ml of dilute nitric acid solution with pH=5, and sonicate until completely dissolved to prepare a bismuth nitrate precursor.

[0048] 3. Mix 10ml sodium tungstate precursor solution with 5ml bismuth nitrate precursor solution to obtain a milky white bismuth tungstate precursor solution, transfer it to a 50ml high-temperature reaction kettle, and conduct a hydrothermal reaction at 250°C for 1 hour. After the hydrothermal treatment, the sediment was washed 5 times with deionized water. The washed sediment was placed in a quartz dish, transferred to a muffle furnace, and sintered at 520° C. for 1.5 h in an air atmosphere. After sintering, grind to obtain powdered bismuth tungstate powder.

[0049] 4. The carbon nano-dot solution is prepared by a simpl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com