Parallel PC component production system

A production system and parallel technology, applied in ceramic molding workshops, ceramic molding machines, manufacturing tools, etc., can solve problems such as high construction costs, constraints on prefabricated buildings, and low production efficiency, so as to reduce production costs and construction costs , to avoid the effect of humidity in the workshop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

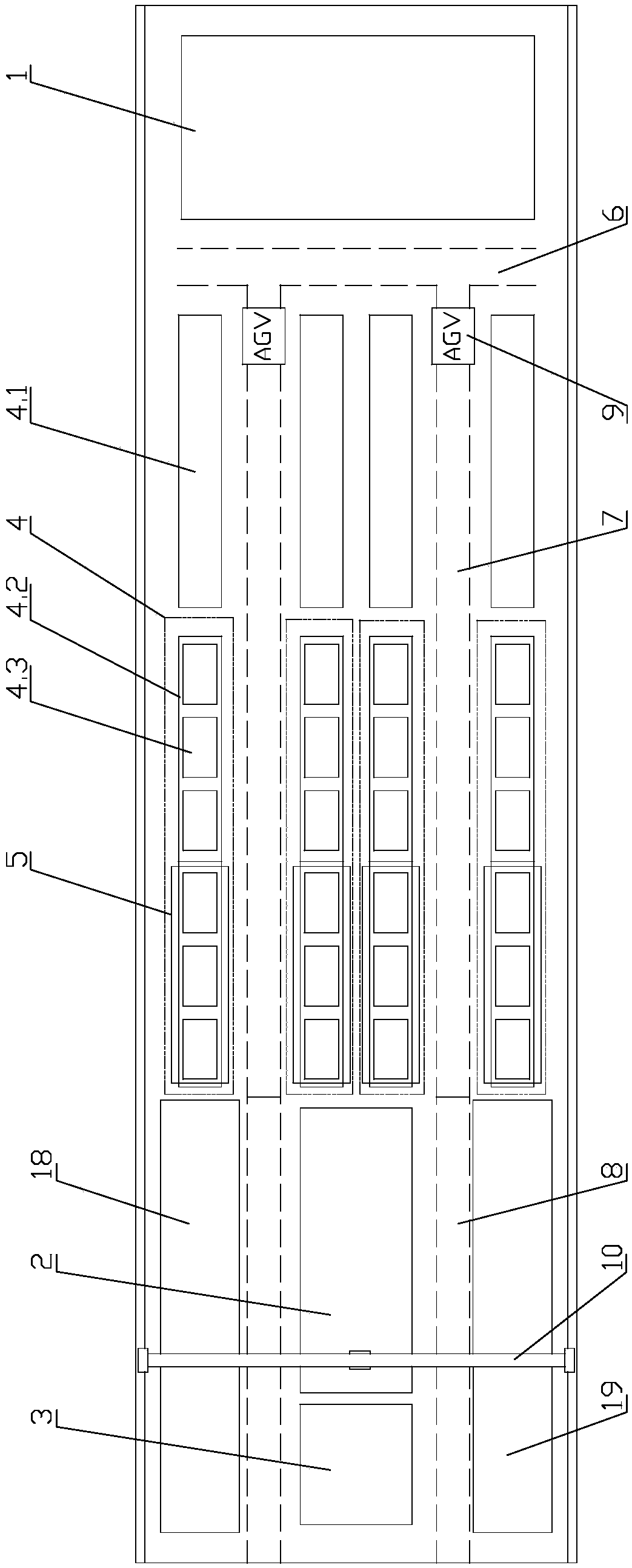

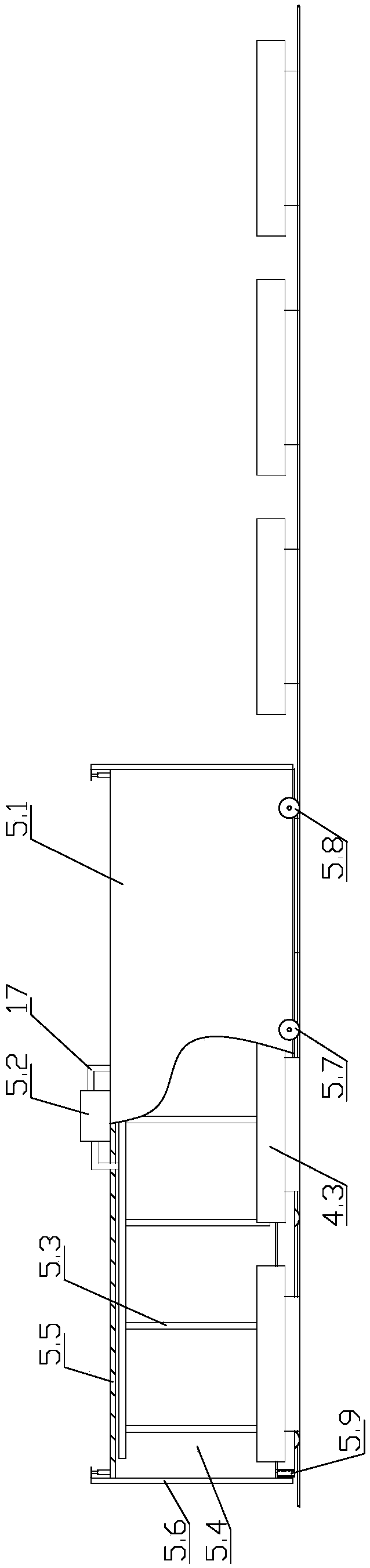

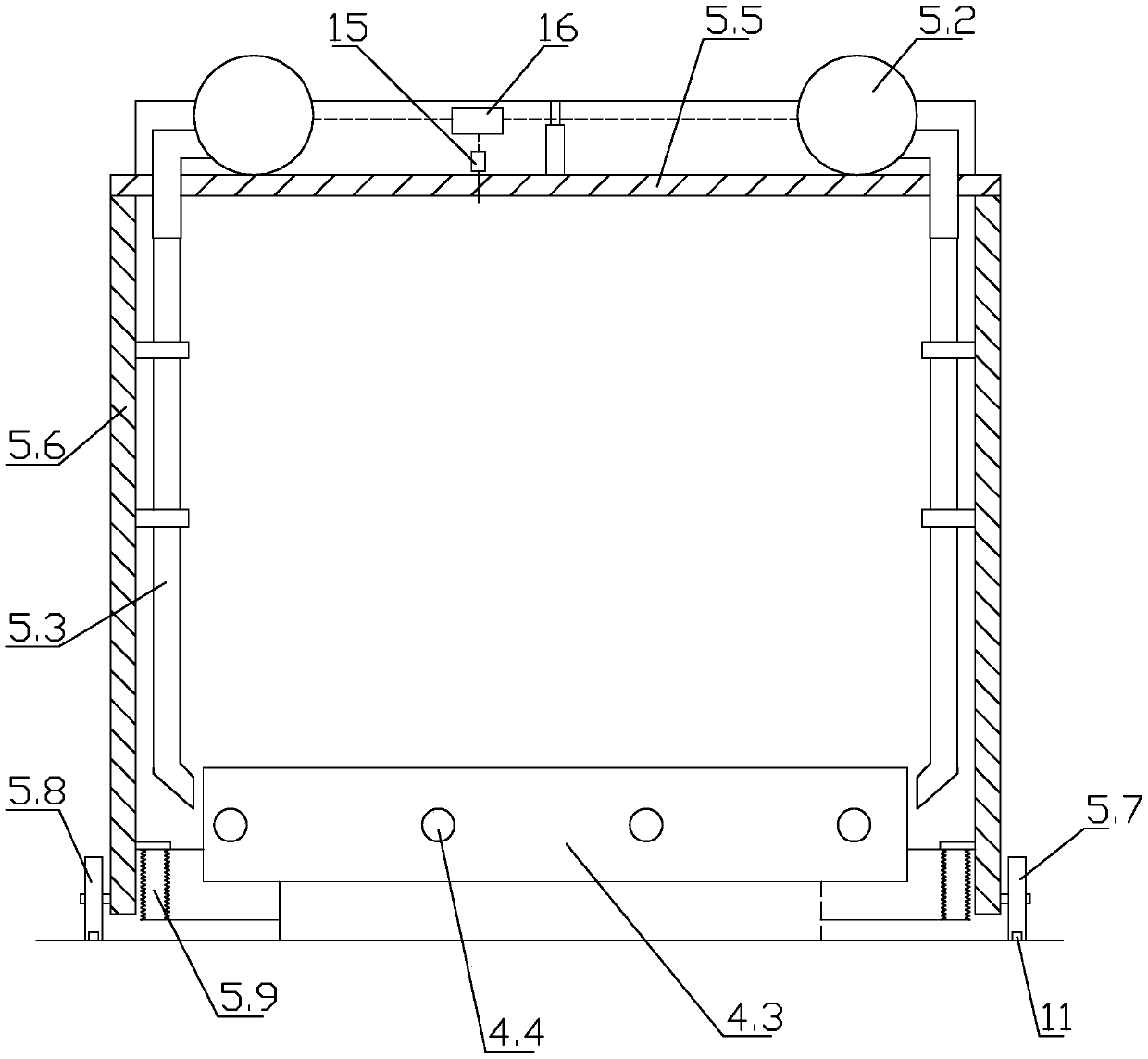

[0021] Such as figure 1 and figure 2 As shown, the parallel-connected PC component production system includes a steel bar CNC processing station 1, a steel bar skeleton processing station 4.1, a component stacking area 18, a component painting station 2, a composite component processing station 3, a finished product stacking area 19 and Several prefabricated component production units 4 are arranged in parallel. Several prefabricated component production units 4 are arranged in parallel. According to production requirements, multiple prefabricated component production units 4 can be used to process different types of PC components at the same time. Various PC component processing and building components The assembly is carried out at the same time, which greatly improves the processing efficiency, and multiple production lines are set up side by side, and the large circulation flow operation greatly reduces the factory area and construction cost;

[0022] The prefabricated c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com