Method for extracting tea polyphenol with low caffeine, no pesticide residue and no ester from tea leaves

A technology with low caffeine and tea polyphenols, applied in the field of extracting low caffeine, ester-free tea polyphenols and no pesticide residues, can solve the problems of long extraction time, high energy consumption and high caffeine content, and achieves short extraction time, Low energy consumption and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

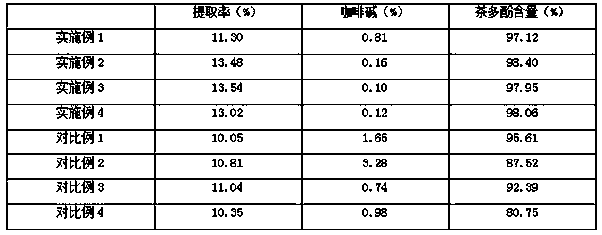

Examples

Embodiment 1

[0033] A method for extracting low caffeine, no pesticide residue, and no ester tea polyphenols from tea leaves, comprising the following steps:

[0034] Step 1: Select fresh green tea leaves, wash them, dry them naturally, grind them to pulverize, pass through a 40-mesh sieve after pulverization, and obtain tea powder;

[0035] Step 2: After raising the temperature of pure water to 90°C, add the tea powder obtained in step 1 and mix. The ratio of solid to liquid between tea powder and pure water is 1g:15ml. After circular countercurrent extraction for 60 minutes, filter, and collect the filtrate to obtain extract Ⅰ;

[0036] Step 3: Adsorb the extract Ⅰ obtained in step 2 through an adsorption resin AB-8 column, the column flow rate is 1BV / h, and then desorb with 100% ethanol to obtain desorption solution Ⅱ;

[0037] Step 4: Put the desorption liquid II mentioned in step 3 under the condition of 65°C, after recovering ethanol in a vacuum, pass through the adsorption resin SA-...

Embodiment 2

[0039] A method for extracting low caffeine, no pesticide residue, and no ester tea polyphenols from tea leaves, comprising the following steps:

[0040]Step 1: select fresh green tea leaves, wash them, dry them naturally, grind them to pulverize, pass through a 60-mesh sieve after pulverization, and obtain tea powder;

[0041] Step 2: After raising the temperature of pure water to 80°C, add β-cyclodextrin according to the ratio of solid-liquid ratio of 1g: 60ml, stir and dissolve, add sodium bicarbonate to adjust the pH of the aqueous solution to the range of 7.5~9.0, and add in step 1 to obtain Mix the tea powder, the solid-liquid ratio of the tea powder and pure water is 1g:20ml, filter after circular countercurrent extraction for 40min, collect the filtrate to obtain the extract Ⅰ;

[0042] Step 3: Adsorb the extract Ⅰ obtained in step 2 through the adsorption resin AB-8 column, the flow rate on the column is 1.5BV / h, and then desorb with 50% ethanol-water solution to obta...

Embodiment 3

[0045] A method for extracting low caffeine, no pesticide residue, and no ester tea polyphenols from tea leaves, comprising the following steps:

[0046] Step 1: select fresh green tea leaves, wash them, dry them naturally, grind them to pulverize, pass through an 80-mesh sieve after pulverization, and obtain tea powder;

[0047] Step 2: After raising the temperature of pure water to 70°C, add β-cyclodextrin according to the ratio of material to liquid: 1g: 70ml, stir and dissolve, add sodium bicarbonate to adjust the pH of the aqueous solution to the range of 7.5~9.0, and add in step 1 to obtain Mix the tea powder, the solid-liquid ratio of the tea powder and pure water is 1g:10ml, filter after leaching for 30min, collect the filtrate to obtain the extract Ⅰ;

[0048] Step 3: Adsorb the extract Ⅰ obtained in step 2 through an adsorption resin AB-8 column, the flow rate on the column is 2BV / h, and then desorb with 70% ethanol-water solution to obtain desorption solution Ⅱ;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com