PVA-based composite material and precursor thereof, remolded product, composite hydrogel, and composite film and preparation and application thereof

A composite hydrogel and composite material technology, which is applied in the field of PVA-based composite materials and their precursors, can solve problems such as toughness and other mechanical properties that cannot meet the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0103] The preparation of embodiment 1 composite material

[0104] Preparation method of composite material:

[0105] 1. Add 15 grams of PVA powder into 285 grams of deionized water, heat (95°C oil bath) to dissolve, and obtain a PVA aqueous solution with a mass fraction of 5%;

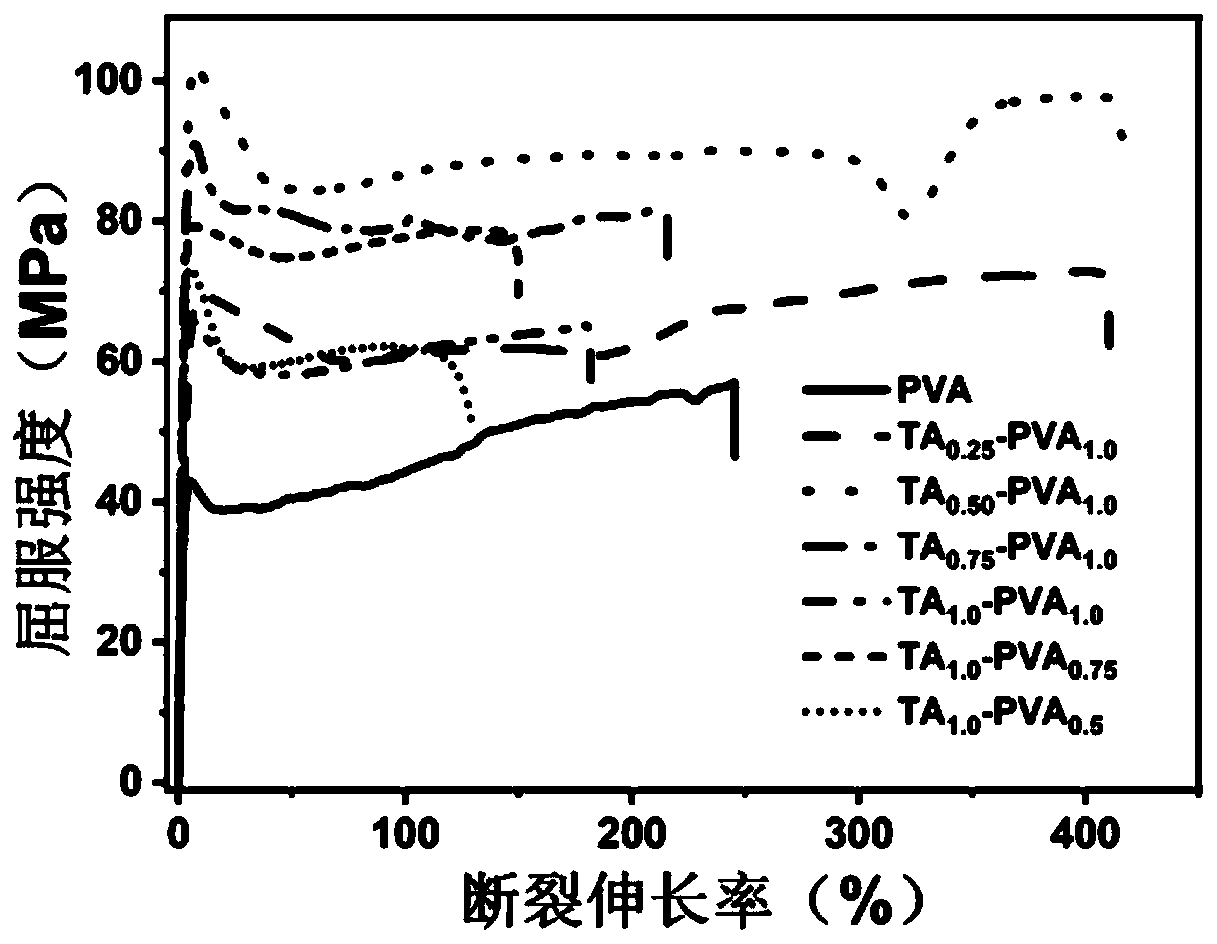

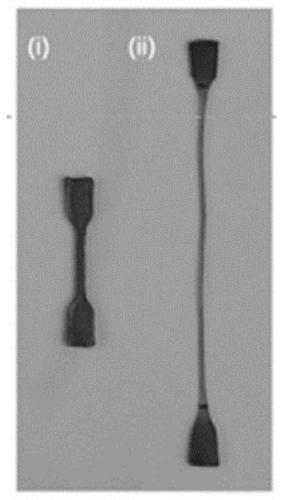

[0106] 2. Mix the 10mg / mL TA aqueous solution and the PVA solution diluted to 10mg / mL at a mass ratio of TA:PVA of 0.25:1.0,0.50:1.0,0.75-1.0,1.0-1.0,1.0-0.75 and 1.0-0.50 , under stirring, adjust the pH value of the above mixed solution to 2.0 with 1mol / L hydrochloric acid to obtain a precipitate;

[0107] 3. Centrifuge the precipitate with a centrifuge to obtain the precursor, and press it through a press (or glass sheet) and dry it.

[0108] Concrete yield test result is as shown in table 1 below:

[0109] Table 1 Test results of different mass ratios

[0110]

[0111] The reaction yield refers to the percentage of the dried mass of the precipitate obtained in the reaction to the sum of the ...

Embodiment 2

[0117] The preparation of embodiment 2 composite hydrogels

[0118] The PVA with a thickness of 150 μm and the TA with a thickness of 150 μm prepared in Example 1 were respectively 0.50 -PVA 1.0 Composite film, TA with a thickness of 150 μm 1.0 -PVA 0.50 The composite membrane was bubbled in deionized water until the sample was saturated with water (referred to as a hydrogel).

Embodiment 3

[0119] The preparation of embodiment 3 composite film

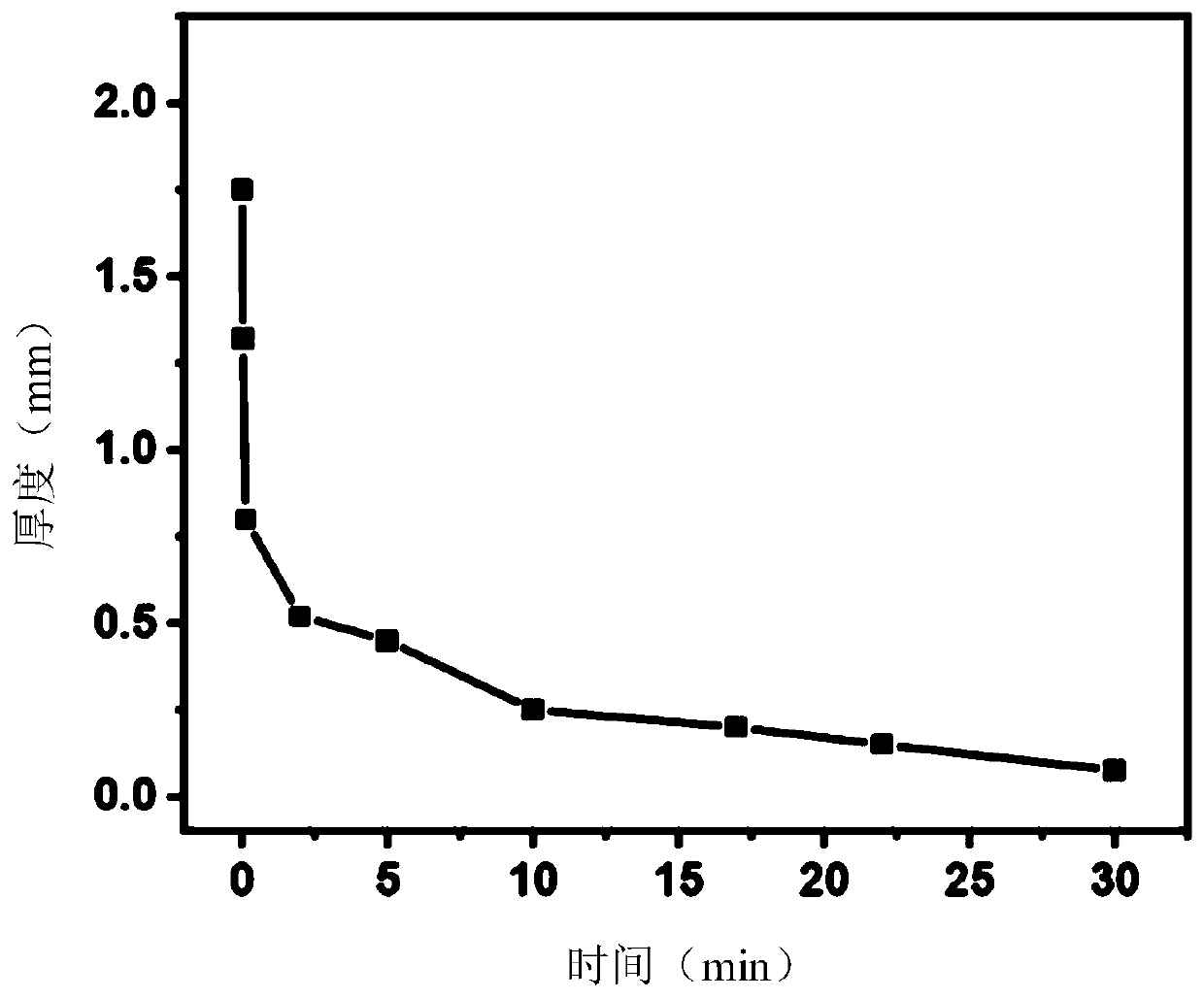

[0120] Film preparation process: the three composite hydrogels of Example 2 were biaxially stretched and fixed, and dried for 20 minutes to obtain a film with a thickness of about 30 μm (thickness can be controlled by the degree of stretching).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com