Unequal height metal grating and manufacturing method thereof

A manufacturing method and metal grating technology, applied in the field of integrated optics, can solve the problems of the same metal grating height and single performance parameters, and achieve good optical performance, flexible adjustment, and strong focusing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

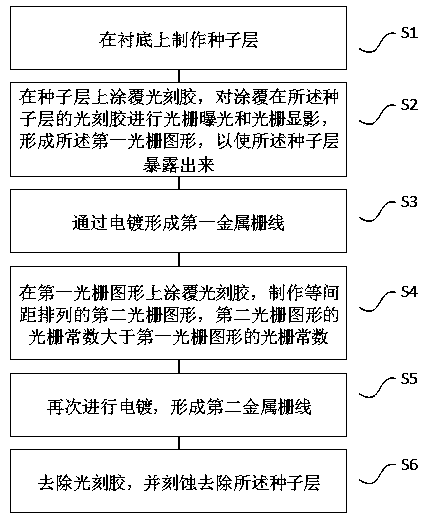

[0061] A method for manufacturing metal gratings with unequal heights, the flow chart is as follows figure 1 shown.

[0062] S1. Fabricate a seed layer 200 on the substrate 100 .

[0063] Such as figure 2 As shown, a 5nm Ti metal layer is first deposited on the substrate 100 by electron beam evaporation technology, and then a 10nm Au metal layer is deposited on the titanium metal layer.

[0064] S2. Coating photoresist 310 on the seed layer 200, performing grating exposure and grating development on the photoresist 310 coated on the seed layer 200, forming the first grating pattern, so that the seed Layer 200 is exposed.

[0065] Such as image 3 As shown, a layer of photoresist 310 is coated on the seed layer 200. The photoresist 310 adopts AZ6130 photoresist with a thickness of 3 microns and is exposed for 3 seconds to make the first grating pattern with 2 micron equidistant intervals, such as Figure 4 As shown, the seed layer 200 is exposed.

[0066] S3, forming the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Grating constant | aaaaa | aaaaa |

| Grating constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com