Feeding method capable of increasing broiler productivity

A feeding method and production performance technology, which is applied in animal feed, animal husbandry, etc., can solve problems such as restricting the increase in feed intake of broilers, mismatching nutritional requirements, and affecting production performance, so as to improve the weight of slaughtered chickens and the performance of broilers Production performance, meeting nutritional needs, and improving production performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

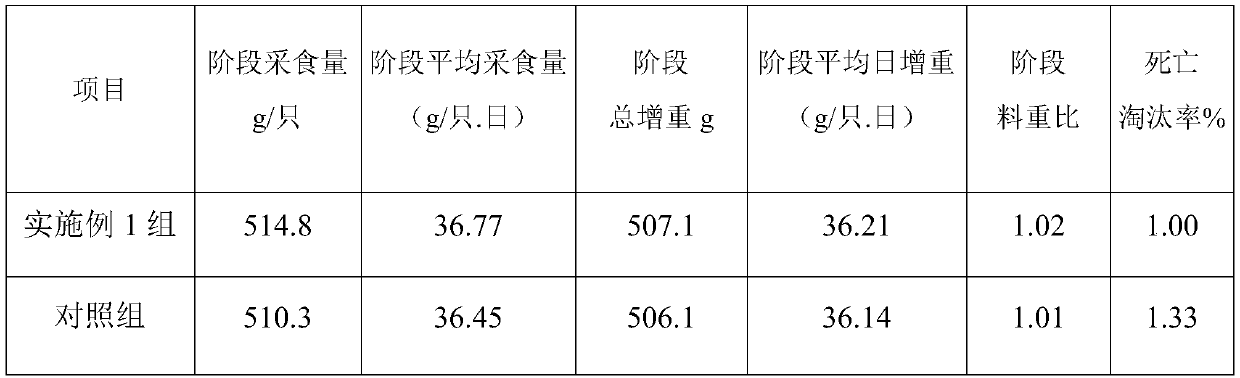

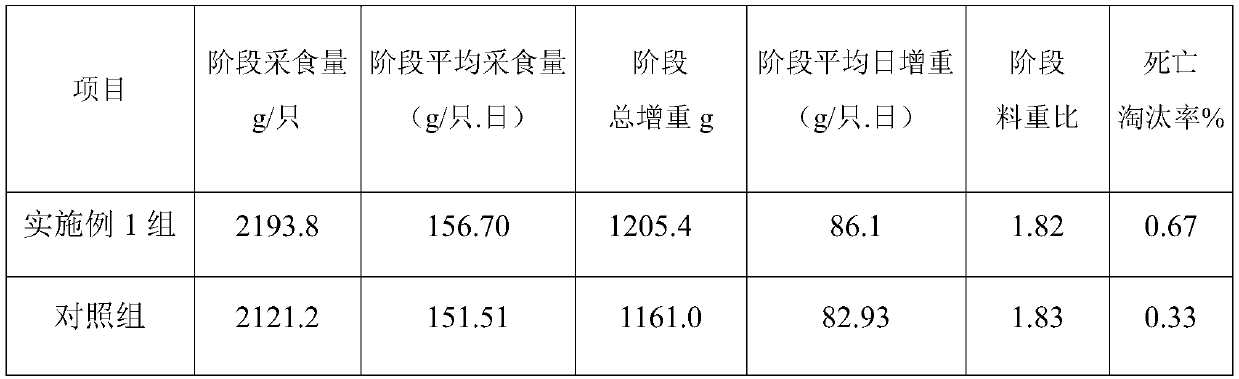

Embodiment 1

[0030] A feeding method for improving the production performance of broilers, the feeding method is divided into four stages, the first stage, hatching to 14 days old; the second stage, 14 days to 21 days old; the third stage, 21 days to 7 days before slaughter; in the fourth stage, from 7 days before slaughter to slaughter; in the second stage, the compound feed consists of corn, soybean meal, corn gluten meal, flour, duck oil, sodium chloride, stone powder, calcium hydrogen phosphate, choline chloride , amino acids, compound vitamins and compound minerals; the compound feed in the fourth stage consists of corn, soybean meal, corn gluten meal, flour, duck oil, sodium chloride, stone powder, calcium hydrogen phosphate, choline chloride, amino acids, compound Composition of vitamins and complex minerals.

[0031] The compound feed in the first stage is composed of the following raw materials in parts by weight: 582 parts of corn, 275 parts of soybean meal, 20 parts of corn glut...

Embodiment 2

[0045] A feeding method for improving the production performance of broiler chickens. The feeding method is divided into four stages. The first stage is from hatching to 14 days old; the second stage is 14 days to 21 days; the third stage is 21 days to 7 days before slaughter; the fourth stage is 7 days before slaughter to slaughter; the compound feed of the second stage is composed of corn, soybean meal, corn gluten meal, flour, duck oil, sodium chloride, stone powder, calcium hydrogen phosphate, choline chloride , amino acids, compound vitamins and compound minerals; the compound feed in the fourth stage consists of corn, soybean meal, corn gluten meal, flour, duck oil, sodium chloride, stone powder, calcium hydrogen phosphate, choline chloride, amino acids, compound Composition of vitamins and complex minerals.

[0046] The compound feed in the first stage is composed of the following raw materials in parts by weight: 568.4 parts of corn, 283 parts of soybean meal, 25 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com