Processing device and method for polybutylene alloy powder

A polybutene alloy and processing device technology, applied in grain processing, separation methods, chemical instruments and methods, etc., can solve problems such as uneven dispersion of antioxidants, uneven particle packing pore density, OIT fluctuations, etc., and achieve improvement Uniform dispersion of additives, improvement of product quality, good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

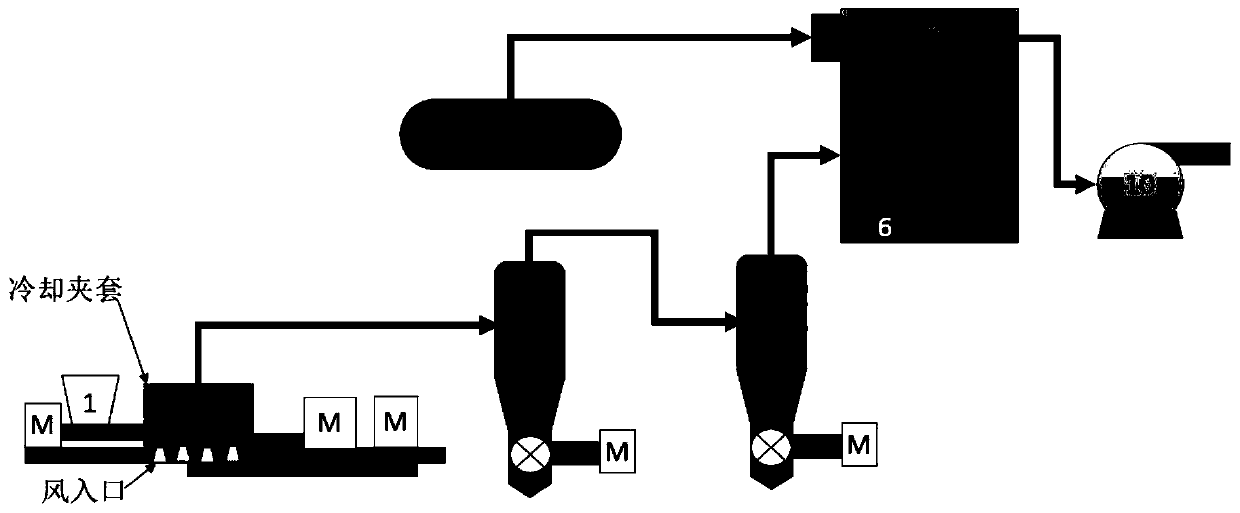

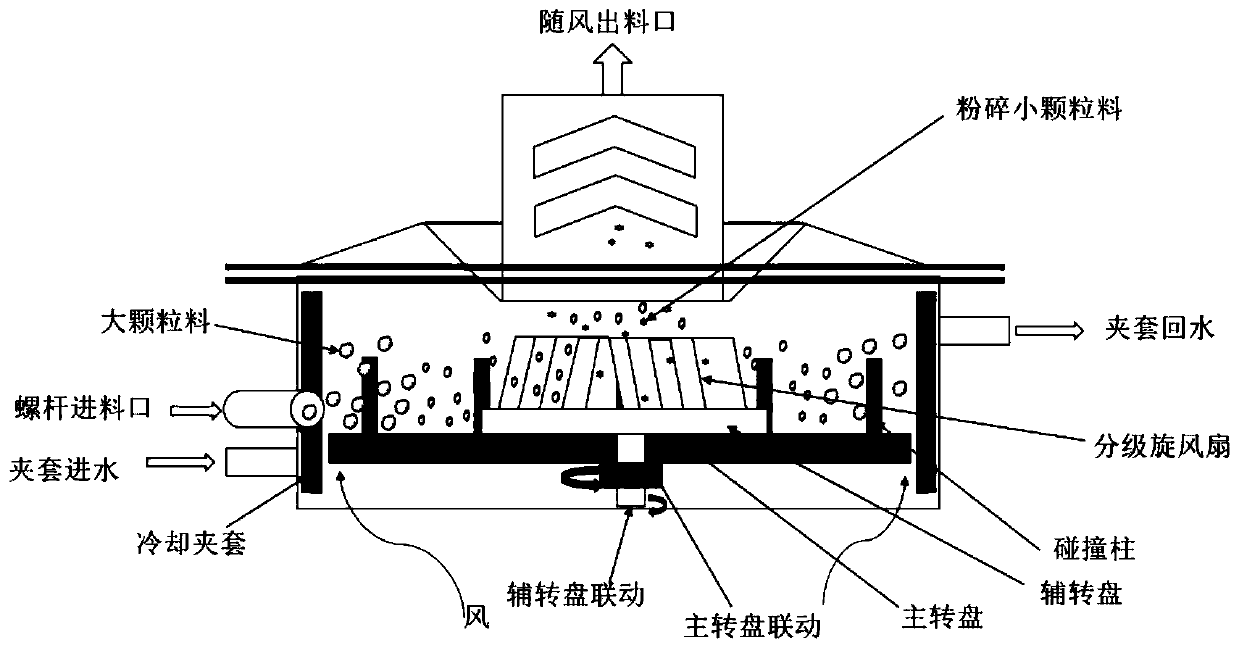

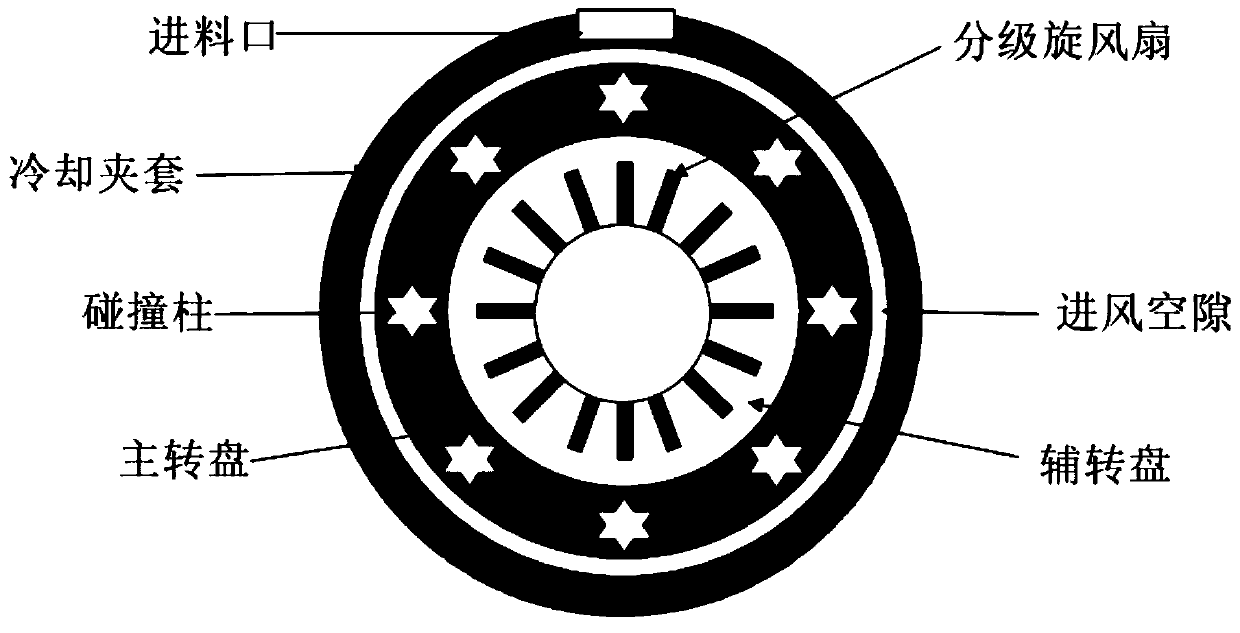

[0077] The structural representation of the processing device of the polybutene alloy powder provided by Example 1 of the present invention can be found in figure 1 As shown; wherein, 1 is a filling device, 2 is a grinding and pulverizing device, 3 is a primary screening device, 4 is a secondary screening device, 5 is a filtering device, 6 is a fine powder storage bin, and 7 is a blowback device, 8 is the draft inlet buffer storehouse, 9 is the purified air storage tank, 10 is the blower fan, and M is the motor; the internal structure and work flow chart of the milling and crushing device in the processing device of the polybutene alloy powder can be found in figure 2 As shown, the internal structure diagram of the milling and pulverizing device in the processing device of the polybutene alloy powder can be found in image 3 As shown; the air inlet at the bottom of the grinding and crushing device includes 8 evenly distributed air outlets, and the main turntable is fixed with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| The maximum diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap