Titanium-gypsum-based material for filling goaf and preparation method thereof

A titanium gypsum and base material technology, applied in the field of titanium gypsum base material and its preparation, can solve problems such as large differences in formulations, and achieve the effects of low cost, shortened final setting time, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 prepares titanium gypsum-based material

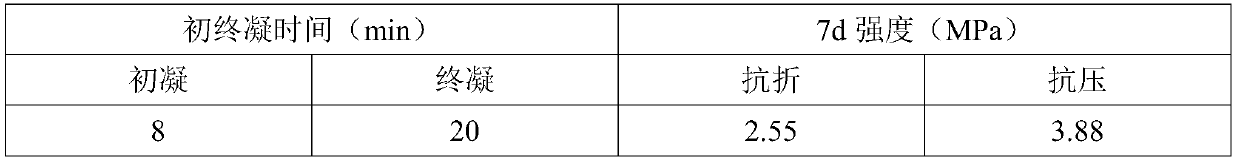

[0028] (1) A titanium gypsum-based material for goaf filling, according to titanium gypsum 80, desulfurization gypsum 6, 425 Portland cement 6, fly ash 3, silica fume 3, slag 2, sodium citrate 1‰ , sodium carboxymethyl cellulose 1‰, naphthalene-based water reducer 3‰, activator 1‰, standard thickness 90% prepared into a triple model, and cured for 7 days at a temperature of 20°C and a humidity of 55%. The relevant test data are shown in the table 1.

[0029] Table 1. Test related data of titanium gypsum material

[0030]

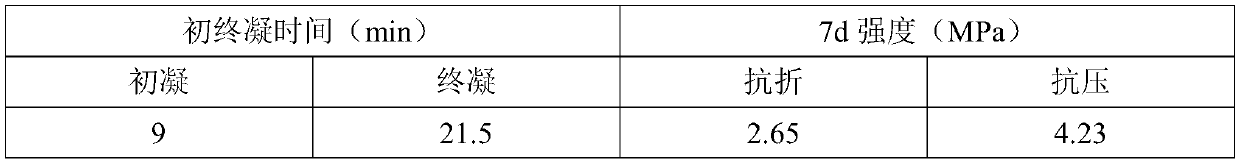

[0031] (2) A titanium gypsum-based material for goaf filling, according to titanium gypsum 75, desulfurization gypsum 5, 425 Portland cement 10, fly ash 5, silica fume 2, slag 3, sodium citrate 1‰ , sodium carboxymethyl cellulose 1.5‰, naphthalene-based water reducer 3‰, activator 1.3‰, standard thickness 95% prepared into a triple model, and cured for 7 days at a temperature of 20°C and a hu...

Embodiment 2

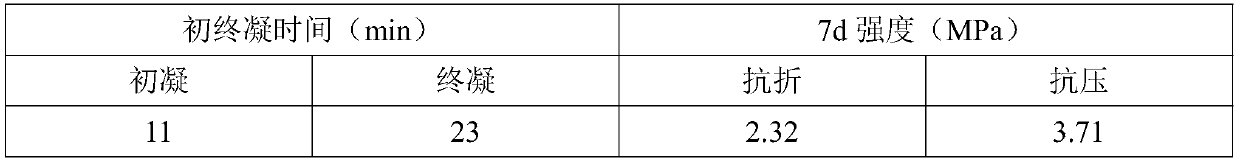

[0038] Take titanium gypsum, desulfurized gypsum, 425 Portland cement, fly ash, silica fume, slag respectively according to the ratio of (1) (2) (3) in embodiment 1, these several kinds of materials are fully mixed, and Pour the mixed materials into the mixed solution of naphthalene-based water reducer, sodium citrate, sodium carboxymethylcellulose, and activator and water that has been stirred, and stir evenly to prepare titanium gypsum-based materials 1, titanium For gypsum-based material 2 and titanium gypsum-based material 3, pour the three kinds of slurries into the Vicat instrument to test the initial and final setting time; at the same time, prepare the slurry according to the above slurry preparation method and pour it into a 40mm*40mm*160mm triple mold After 1.5-2 hours, demould, put it in an environment of 20±1°C and humidity 50-65% for 7 days, and then dry it at 42°C to test its 7d strength

[0039] The control group is set to use ordinary cement, and the cement-bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com